48

Do not apply excessive force to the stop valve after fully opening. Otherwise, the stop valve will blow out due

to refrigerant pressure. At the test run, fully open the stop valve. Otherwise, these devices will be damaged.

(It is closed before shipment.)

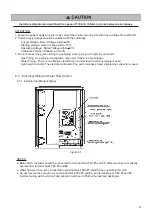

Caution for Opening Stop Valve

1. Do not apply an excessive force after fully opening the stop valve (Tightening Torque: < 5.0 N·m).

(This valve does not have a hard stop when opening, and allows for the complete removal of the valve

stem.)

2. Securely tighten the caps according to the torque specifications in Section 7.2.1 after each stop valve is

opened.

Hexagonal Wrench Size [mm]

Model

Gas Valve Liquid Valve

76, 96

5

5

114

, 136, 154

10

170 - 190

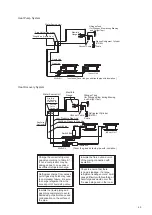

9.3 Charging Work

(1) An additional refrigerant charge is required according to total piping length. Refer to Table 9.1.

(2) After vacuum pumping work, check that the high/low pressure gas valve (low pressure gas valve is for

heat recovery system only), and liquid stop valve are fully closed.

Charge the additional refrigerant from the access port of liquid stop valve (acceptable error must

be within 0.5 kg).

(3) After refrigerant has been charged, fully open the liquid stop valve and gas stop valves.

Gas remaining at the O-ring or screw component may emit a hissing sound when removing the stop

valve cap. However, this is not leaking gas.

(4) If it proves impossible to dispense the specified (charged) quantity of refrigerant, follow the procedure

below.

(a) Fully open the stop valve at the gas line side (for heat recovery system, both stop valves of high/low

pressure and low pressure side).

(b) Operate the compressor in the cooling mode and charge the additional refrigerant from the access

port of the liquid stop valve. An acceptable error must fall within 0.5 kg. At this time, keep

the liquid stop valve slightly open.

(c) After the refrigerant is charged, fully open the liquid stop valve and the gas stop valve.

(d) Carefully calculate any additional refrigerant quantity for charging. If the quantity of additional

refrigerant is not correct, it might cause a compressor failure. The additional refrigerant must be

charged in a liquid condition.

(e) Refrigerant charge from the access port on the gas stop valve can lead to compressor failure.

Be sure to charge refrigerant from the access port on the liquid stop valve.

Refrigerant

Pressure

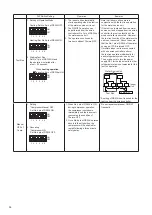

Stop Valve

Counterclockwise...Open

Clockwise...............Close

Only the charging

hose for R410A

can be connected.

Access Port

Cap

O-ring

(Rubber)

Hexagonal

Wrench

To open or

close the

stop valve

Closed before Shipment

Summary of Contents for AVWW-114FKFW

Page 2: ......