3.2 Installation

3.2.1 Suspension bolts

(1) Consider the pipe direction, wiring and maintenance

carefully, and choose the proper direction and location

for installation.

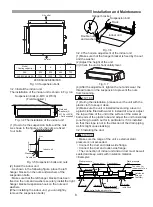

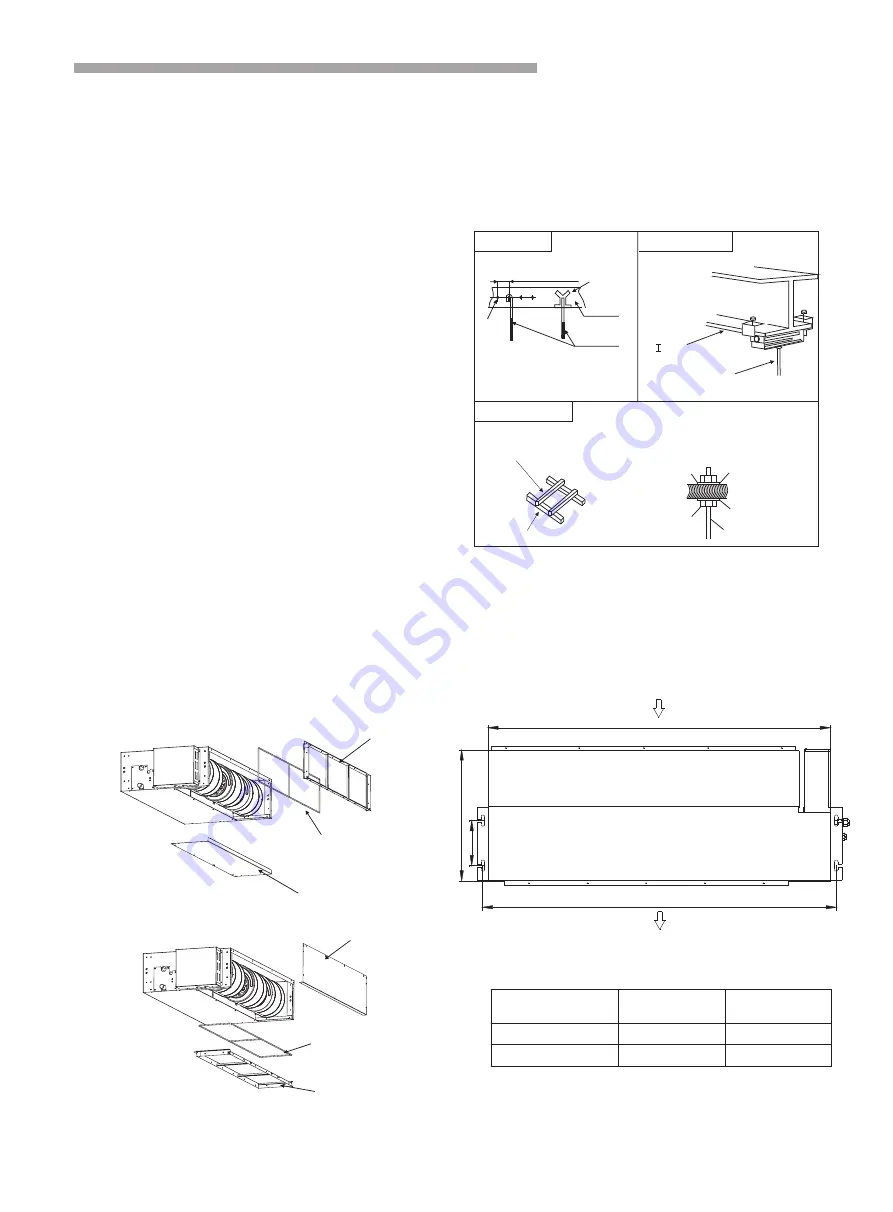

(2) Install the suspension bolts as shown in Fig. 3.2

below.

Fig. 3.2.1 Fixing the suspension bolts

·

For the concrete

·

For the steel beam

·

For the wooden beam

150 to160mm

Screw in

(

100 to150kg

)

Steel bar

Concrete

Suspension bolts

(W3/8 or M10)

“

”

shaped steel beam

Wood rib

60mm to 90mm

(

)

Wooden beam

Nut

Round washer

Square washer

Suspension bolts

7

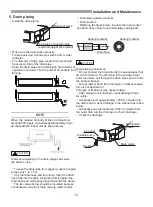

3.2.2 The position of the suspension bolts and the pipes

(1) Mark the positions of the

, the

positions of the refrigerant pipes and the drain pipes.

(2) The dimension are shown below.

suspension bolts

Installation and Maintenance

·

Optimum air distribution is ensured.

The air passage is not blocked.

Condensate can drain properly.

The ceiling is strong enough to bear the weight of the

indoor unit.

A false ceiling does not seem to be at an incline.

Sufficient clearance for maintenance and servicing

is ensured.(See Fig.3.1.1,Fig3.1.2 )

Piping between the indoor and outdoor units is within

the allowable limits.(refer to the installation of the

outdoor unit )

The indoor unit, outdoor unit, power supply wiring

and transmission wiring is at least 1 meter away from

televisions and radio, this prevents image interference

and noise in electrical appliances.

(Noise may be generated depending on the conditions

under which the electric wave is generated, even if a

one-meter allowance is maintained.)

Use suspension bolts to install the unit, check whether

or not the ceiling is strong enough to support the weight

of the unit. If there is a risk that the ceiling is not strong

enough, reinforce the ceiling before installing the unit.

For bottom intake, replace the chamber lid and the

intake-side flange in the procedure listed in fig.

(1)Remove the intake-side flange.

Remove the chamber lid.

(2)Reattach the removed chamber lid in the orientation

shown in FIG, reattach the removed the intake-side

flange in the orientation shown in Fig. 3.1.3, refer to

Fig.3.1.4 for the direction of the intake-side flange.

·

·

·

·

·

·

·

·

·

Do

not

install

the

indoor

unit

in

a machinery

shop

or

kitchen

where

vapor

from

oil

or

its

mist

flows to

the

indoor

unit

.

The

oil

will

deposit

on

the

heat

exchanger, thereby

reducing

the

indoor

unit

performance, and

may

deform

and

in

the

worst

case,

break

the

plastic

parts

of

the

indoor

unit.

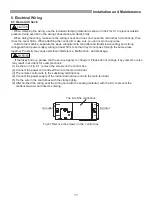

Suspension bolts

(W3/8 or M10)

Nut

Fig. 3.1.3

Fig. 3.1.4

Intake-side flange

Chamber lid

Intake-side flange

Chamber lid

Filter

(

invalid

for

Filter

(

invalid

for

some

models

)

some

models

)

.1

9K/12K/18K

Air inlet

Air outlet

b

15

4

44

7

a

Model

(

Cooling capacity

)

a

b

9K/12K

937

900

18K

1207

1170

Summary of Contents for DC Inverter Unitary Series

Page 81: ......

Page 82: ......

Page 84: ......

Page 87: ...4 SI L N SI L N N L SI L N SI L N N W V U 42K 48K 60K 9K 12K 18K 24K 36K...

Page 88: ...5...

Page 94: ...11...

Page 97: ...14...

Page 98: ...15 2...

Page 100: ...Version No 1939214 A...