GENERAL INFORMATION

- 11 -

Screwdrivers

Screwdrivers of various lengths and types are mandatory for the simplest tool kit. The two basic

types are the slotted tip (flat blade) and the Phillips tip. These are available in sets that often include an

assortment of tip size and shaft lengths.

As with all tools, use a screwdriver designed for the job. Make sure the size of the fastener. Use

them only for driving screws. Never use a screwdriver for

prying or chiseling metal. Repair or replace worn or

damaged screwdrivers. A worn tip may damage the

fastener, making it difficult to remove.

Phillips-head screws are often damaged by

incorrectly fitting screwdrivers. Quality Phillips

screwdrivers are manufactured with their crosshead tip

machined to Phillips Screw Company specifications.

Poor quality or damaged Phillips screwdrivers can back

out (cam out) and round over the screw head. In addition.

Weak or soft screw materials can make removal difficult.

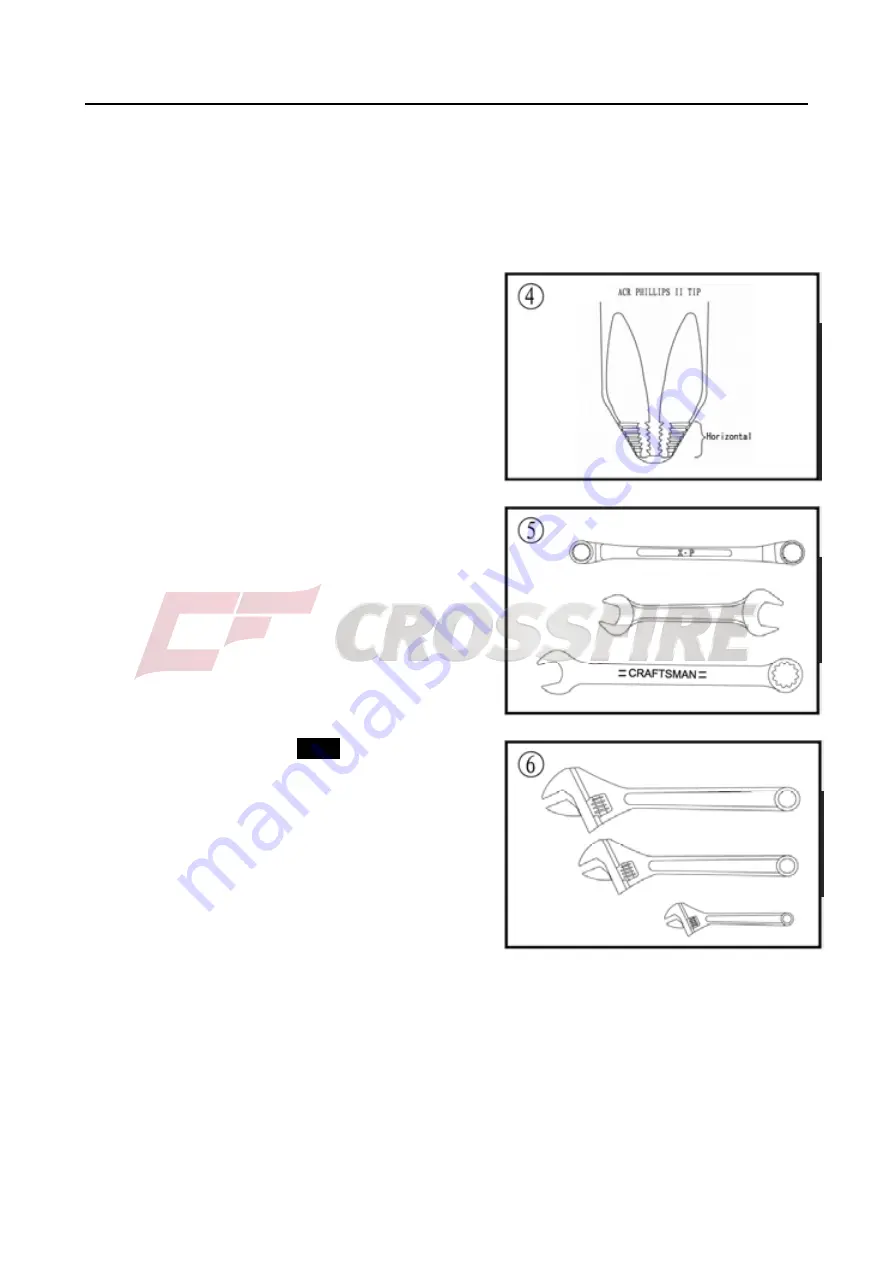

The best type of screwdriver to use on Phillips

screw is the ACR Phillips II screwdriver, patented by the

horizontal anti-cam out ribs found on the driving faces or

flutes of the screwdriver’s tip (figure 4). ACR Phillips II

screwdrivers were designed as part of a manufacturing

drive system to be used with ACR Phillips II screws, but

they work of tool companies offer ACR Phillips II

screwdrivers in different Tip size and interchangeable

bits to fit screwdriver bit holders.

NOTE

Another way to prevent cam out and to increase

the grip of a Phillips screwdriver is to apply valve

grinding compound or permute screw

&

socket

Gripper onto the screwdriver tip.After

loosening/tightening the screw, clean the screw

recess to prevent engine oil contamination.

Wrenches

Open-end, box-end and combination wrenches (figure 5) are available in a variety of types and

sizes.

The number stamped on the wrench refers to the distance of the fastener head.

The box-end wrench is an excellent tool because it grips the fastener on all sides. This reduces

the chance of the tool slipping. The box-end wrench is designed with either a 6 or 12-point opening.

For stubborn or damaged fasteners, the 6-point provides superior holding because it contacts the

fastener across a wider area at all six edges. For general use, the 12-point works well. It allows the

wrench to be removed and reinstalled without moving the handle over such a wide are.