15

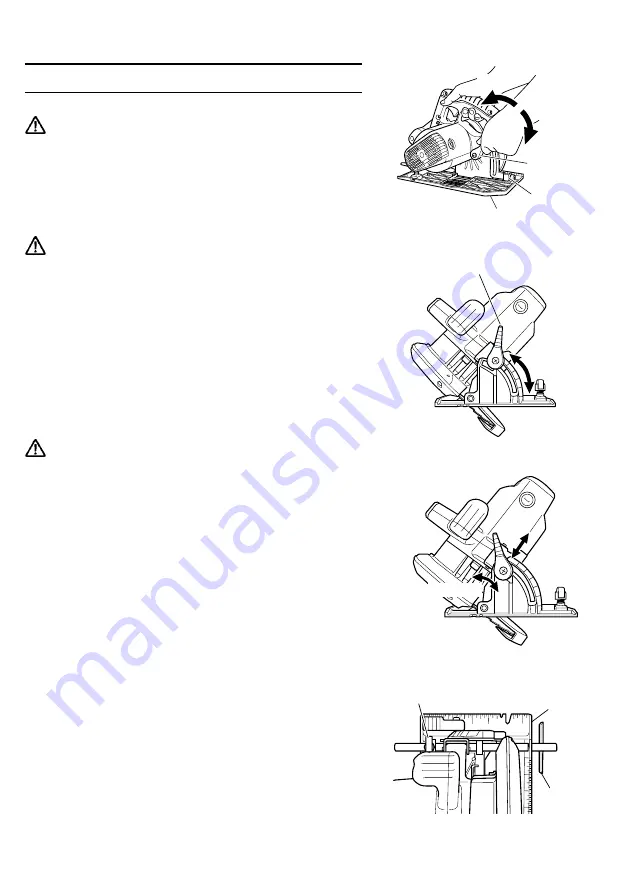

ADJUSTSING THE SAW PRIOR TO USE

WARNING:

To avoid serious accidents, ensure the switch

is in OFF position, and disconnect the plug

from the receptacle.

1. Adjusting the cutting depth (Fig. 10)

WARNING:

If the lever (A) is loose, injury can result.

Tighten it securely after adjustment.

To adjust cutting depth, loosen the lever (A)

and, while holding the base with one hand,

move the main body up and down to obtain

the prescribed cutting depth. After adjusting

to the prescribed cutting depth, tighten the

lever (A) securely.

2. Adjusting the angle of inclination

WARNING:

If the lever (A) is loose, injury can result.

Tighten it securely after adjustment.

You can incline saw blade from 0˚ to a

maximun angle of 55˚ in relation to the base.

As shown in Fig. 11 by loosing the lever (A) on

the bevel scale, the saw blade may be inclined

to an angle of 45˚ in relation to the base.

If you use inclination angle of over 45˚, as

shown in Fig. 12 move the lever (A) to inside,

the saw blade may be inclined to a maximum

angle of 55˚ in relation to the base.

Always ensure that the lever (A) is thoroughly

tightened after making the desired adjustment.

3. Regulating the guide (Rip fence)

The cutting position can be regulated by

moving the guide to the left or right after

loosening its wing-bolt. The guide may be

mounted on either the right or left side of the

tool. (See Fig. 13)

Fig. 10

Fig. 11

Wing Bolt, Lock Spring

Base

0˚ – 45˚

Fig. 12

Fig. 13

Guide

(Rip Fence)

Lever (A)

Tighten

Link

Base

Lever (A)

45˚ – 55˚

Loosen

Summary of Contents for C 7SB2

Page 22: ...22 ...

Page 23: ...23 ...

Page 24: ...401 Code No C99120213 Printed in China Hitachi Koki Co Ltd ...