8

English

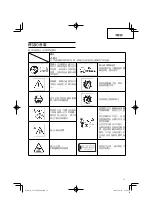

SPECIFICATIONS

MODEL

CG31EBS

CG31EBS

(

L

)

Engine

Size (ml)

30.8

Spark Plug

CHAMPION RCJ6Y

Fuel Tank

Capacity (l)

0.67

Dry Weight

(kg)

6.4

5.8

ASSEMBLY

PROCEDURES

Drive

shaft

to

engine

(

Fig.

1

)

Loosen tube locking bolt (1) about ten turns so that the

bolt point will not obstruct drive shaft tube to be inserted.

When inserting drive shaft tube, hold the tube locking bolt

outward preventing inside

fi

tting from obstructing as well.

NOTE

When it is hard to insert drive shaft up to the marked

position on the drive shaft tube, turn drive shaft by the

cutter mounting end clockwise or counter-clockwise.

Tighten tube locking bolt lining up the hole in the shaft

tube. Then tighten clamp bolt securely (1).

Installation

of

handle

Remove the handle bracket (2) from the assembly. (

Fig.

2

)

Place the handles and attach the handle bracket with four

bolts lightly. Adjust to appropriate position. Then

fi

x it

fi

rmly

with the bolts.

Fix protection tube on drive shaft or handle using cord

clamps (3). (

Fig.

3

)

NOTE

If the protection tube is set apart from the handle or pipe,

it will be caught by something during operation and it

may cause serious injury. Do not set the protection tube

apart from the handle or pipe.

Throttle

wire

/

stop

cord

Remove air cleaner cover. (

Fig.

4

)

Loosen and remove the screw from the throttle wire holder.

(

Fig.

6

)

Connect the terminals of the stop cords coming out from

the engine and shaft. (

Fig.

5

)

Hook the throttle wire end on the throttle of the carburetor.

Make sure that the throttle lever shown in the

Fig.15

is set

at the “idle” position.

Put the throttle outer end into the groove, and then cover

it with the throttle wire holder and

fi

x the holder with the

screw. (

Fig.

7

)

Then, install the cleaner cover.

Fix the protection tube which the stop cords and throttle

wire are passing through, on the pipe with the hip pad.

Then, as shown in the

fi

gure,

fi

x the protection tube on the

pipe and handle with the bands in the bag.

After

fi

xing, cut o

ff

the extra part of the band not to obstruct

the operation. (

Fig.

3

)

NOTE

If the protection tube is set apart from the handle or

pipe, it will be caught by something during operation

and it may cause serious injury.

Do not set the protection tube apart from the handle or

pipe.

Installation

of

blade

guard

(

Fig.

9

)

Install the blade guard on drive shaft tube against angle

transmission (4). Tighten the guard bracket

fi

rmly so that

the blade guard does not swing or move down during

operation.

Install the gear case and blade guard so that blade guard

contacts the gear case. (

Fig.10

)

CAUTION

The blade guard must be in place when operating.

If the blade guard is not in place when operating, you

may get the serious injury.

Installation

of

cutting

blade

(

Fig.

11

)

When installing a cutting blade, make sure that there are no

cracks or any damage in it and that the cutting edges are

facing the correct direction.

Align the notch hole of the cutter holder with the hole on the

gear case (Top the gear case) and insert the Allen wrench

to stop turning. Turn the

fi

xing nut clockwise and remove

the

fi

xing nut, cutter holder cap, and toothed lock washers.

The installation of the cutting blade is as follows: insert the

Allen wrench into the notch hole of the cutter holder and

the hole on the gear case. Then, install the cutting blade

(check the installing direction, as referring to

Fig.

13

), the

cutter holder cap and toothed lock washers onto the cutter

holder in this order. Finally, tighten the

fi

xing nut securely

by turning counterclockwise with the Combi box spanner.

(

Fig.

11

)

CAUTION

○

When installing the cutting blade, set its center hole to

the convex part of the cutter holder and hold it with the

concave surface of the cutter holder cap. Then, tighten

the

fi

xing nut to prevent the cutting blade from being

eccentric. (

Fig.

12

)

After installing the cutting blade, be sure to remove the

Allen wrench and Combi box spanner.

○

Before operation, make sure the blade has been

properly installed.

○

Cutter holder cap under a cutting blade, check it for

wear or cracks before operation. If any damage or wear

is found, replace it, as it is an article of consumption.

NOTE

The blade must be retained with a new cotter pin each

time installed. (

Fig.

11

)

OPERATING

PROCEDURES

Fuel

(

Fig.

14

)

WARNING

○

The Brush cutter is equipped with a two-stroke engine.

Always run the engine on fuel, which is mixed with oil.

Provide good ventilation, when fueling or handling fuel.

○

Fuel contains highly

fl

ammable and it is possible to get

the serious personal injury when inhaling or spilling on

your body. Always pay attention when handling fuel.

Always have good ventilation when handling fuel inside

building.

Fuel

○

Always use branded 89 octane unleaded gasoline.

○

Use genuine two-cycle oil or use a mix between 25:1

to 50:1, please consult the oil bottle for the ratio or

HITACHI dealer.

○

If genuine oil is not available, use an anti-oxidant added

quality oil expressly labeled for air-cooled 2-cycle

engine use (JASO FC GRADE OIL or ISO EGC GRADE).

Do not use BIA or TCW (2-stroke water-cooling type)

mixed oil.

000Book̲CG31EBS̲Tha.indb 8

000Book̲CG31EBS̲Tha.indb 8

2009/06/30 16:29:12

2009/06/30 16:29:12