5

English

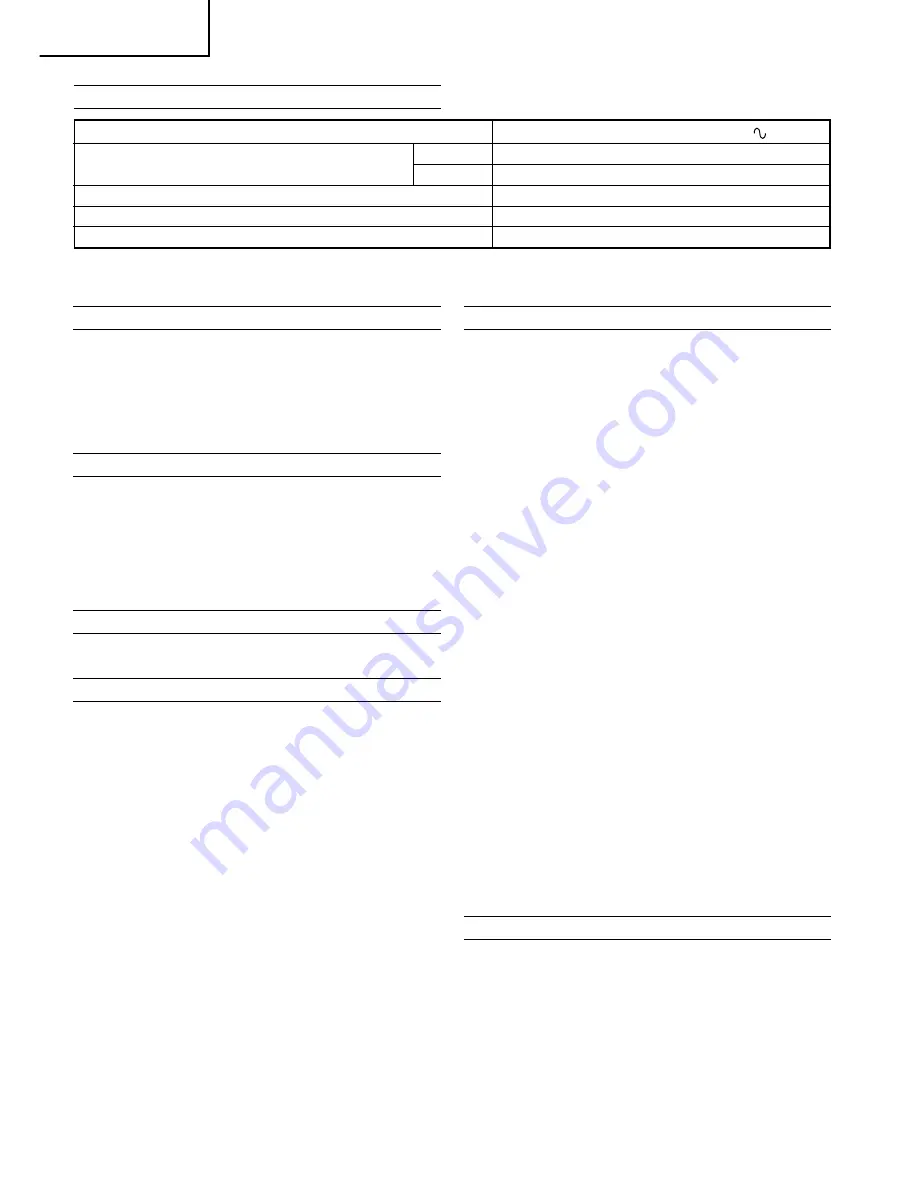

SPECIFICATIONS

STANDARD ACCESSORIES

(1) Saw Blade (Dia. 165 mm) (mounted on tool ) ..... 1

(2) Box Wrench ............................................................... 1

(3) Guide .......................................................................... 1

(4) Wing-bolt ................................................................... 1

Standard accessories are subject to change without

notice.

OPTIONAL ACCESSORIES (sold separately)

(1) Dust Collector Set

Connect the suction hose to collect saw dust with

the vacuum cleaner (see

Fig. 12

).

(2) Washer (A) ... for 16 mm (Inner dia. of saw blade)

... for 30 mm (Inner dia. of saw blade)

Optional accessories are subject to change without notice.

APPLICATION

Cutting various types of wood.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specified on the product

nameplate.

2. Power switch

Ensure that the power switch is in the OFF position.

If the plug is connected to a receptacle while the

power switch is in the ON position, the power tool

will start operating immediately, which could cause

a serious accident.

3. Extension cord

When the work area is removed from the power

source, use an extension cord of sufficient thickness

and rated capacity. The extension cord should be

kept as short as practicable.

4. Prepare a wooden workbench (Fig. 1)

Since the saw blade will extend beyond the lower

surface of the lumber, place the lumber on a

workbench when cutting. If a square block is utilized

as a workbench, select level ground to ensure it

is properly stabilized. An unstable workbench will

result in hazardous operation.

CAUTION

To avoid possible accident, always ensure that the

portion of lumber remaining after cutting is securely

anchored or held in position.

ADJUSTING THE SAW PRIOR TO USE

1. Adjusting the cutting depth

As shown in

Fig. 2

, hold the handle with one hand

while loosening the knob with the other.

The cutting depth can be adjusted by moving the

base to the desired position. In such manner adjust

the cutting depth and then securely retighten the

knob.

2. Adjusting the riving knife

Loosen the hexagonal – head bolt used to clamp

the riving knife, adjust the riving knife to the position

shown in

Fig. 3

and securely retighten the bolt.

3. Adjusting the angle of inclination

As shown in

Fig. 4 (A)

,

Fig. 4 (B)

by loosening the

knob on the incline gauge and the wing-bolt on the

base, the saw blade may be inclined to a maximum

angle of 45° in relation to the base. After having

completed the adjustment, reconfirm that the knob

and the wing-bolt are firmly tightened.

4. Adjusting the guide piece

On the circular saw, it is possible to make fine

adjustment of the fixing position of the guide piece,

where the saw blade and the premarked line are

to be aligned.

When the saw is shipped from the factory, the

linear portion of a notch on the guide piece is

aligned with the central position of the saw blade.

(

Fig. 5 (A)

)

Loosen the fixed screw on the guide piece, should

the fixing position be wrong, and make necessary

adjustment of the position. (

Fig. 5 (B)

)

5. Regulating the guide (Fig. 6)

The cutting position can be regulated by moving

the guide to the left or right after loosening its

wingbolt. The guide may be mounted on either the

right or left side of the tool.

CUTTING PROCEDURES

1. Place the saw body (base) on the lumber, and align

the premarked line with the saw blade by use of

the front scale. When the saw blade is not inclined,

the right-hand side (marked “O” on the guide piece)

is the reference (

Fig. 7 (A)

); when the saw blade

is inclined (45°), the left-hand side (marked “45” on

the guide piece) is the reference (

Fig. 7 (B)

).

2. Ensure that the switch is turned to the ON position

before the saw blade comes in contact with the

lumber. The switch is turned ON when the trigger

is squeezed; and OFF when the trigger is released.

*Be sure to check the nameplate on product as it is subject to change by areas.

Voltage (by areas)*

(110V, 220V, 230V, 240V)

Cutting Depth

90°

0 ~ 55 mm

45°

max. 40 mm

Power Input

950W*

No-Load Speed

4700/min

Weight (without cord)

3.5 kg