3

DP33KA/B

IMPORTANT SAFETY INSTRUCTION

1. Before returning an instrument to the customer, always

make a safety check of the entire instrument, including

but not limited to the following items.

a. Be sure that no built-in protective devices are

defective and/or have been deleted during servicing.

(1) Protective shields are provided on this chassis to

protect both the technician and the customer.

Correctly replace all missing protective shields,

including any removed for servicing convenience. (2)

When reinstalling the chassis and/or other assembly

in the cabinet, be sure to put back in place all

protective devices, including but not limited to,

nonmetallic control knobs, insulating fishpaper,

adjustment and compartment covers/shields, and

isolation resistor/capacitor networks. Do not operate

this instrument or permit it to be operated without

all protective devices correctly installed and

functioning. Servicers who defeat safety features

or fail to perform safety checks may be liable for

any resulting damage.

b. Be sure that there are no cabinet openings through

which an adult or child might be able to insert their

fingers and contact a hazardous voltage. Such

openings include, but are not limited to (1) spacing

between the picture tube and cabinet mask, (2)

excessively wide cabinet ventilation slots, and (3) an

improperly fitted and/or incorrectly secured cabinet

back cover.

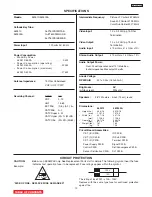

c. Antenna Cold Check – With the instrument AC plug

removed from any AC source, connect an electrical

jumper across the two AC plug prongs. Place the

instrument AC switch in the on position. Connect one

lead of an ohmmeter to the AC plug prongs tied

together and touch the other ohmmeter lead in turn to

each tuner antenna input, exposed terminal screw

and, if applicable, to the coaxial connector. If the

measured resistance is less than 1.0 megohms or

greater than 5.2 megohms, an abnormality exists that

must be corrected before the instrument is returned to

the customer. Repeat this test with the instrument AC

switch in the off position.

d.

Leakage Current Hot Check -

Plug the AC line cord

directly into a 120V AC 60Hz outlet

(do not use an

isolated transformer for this check). Turn the

A C

power ON. Using a Leakage Current Tester (Simpson’s

Model 228 or equivalent), measure for current from all

exposed metal parts of the cabinet (antennas,

screwheads,

overlays, control shafts, etc.)

particularly any exposed

metal part

having a return path to the chassis or to a

known earth ground (water pipe, conduit, etc.). Any

current measured must not exceed 0.5 MIU.

e. High Voltage – This receiver is provided with a

hold down circuit for clearly indicating that voltage has

increased in excess of a predetermined value.

Comply will all notes described in this Service Manual

regarding this hold down circuit when servicing, so

that this hold down circuit may correctly be operated.

f. Service Warning – With maximum contrast, operating

high voltage in this receiver is lower than 30.5 kV. In

case any component having influence on high voltage

is replaced, confirm that the high voltage with

maximum contrast is lower than 30.5 kV.

To measure H.V. use a high impedance H.V. meter.

Connect (-) to chassis earth and (+) to the CRT anode

button. (See the following connection diagram.)

Note: Turn power switch off without fail before the

connection to the anode button is made.

Chassis

ground

High Impedance

H.V. meter

Deflection P.W.B.

FBT

(TH01)

High voltage

connector

+ -

LEAKAGE

CURRENT

TESTER

DEVICE

UNDER

TEST

TEST ALL

EXPOSED

METAL

SURFACES

2-WIRE CORD

(READING

SHOULD NOT

BE ABOVE

0.5 mA)

EARTH

GROUND

ALSO TEST WITH

PLUG REVERSED (USING

AC ADAPTER PLUS

AS REQUIRED)

AC LEAKAGE TEST

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE RECEIVER TO THE CUSTOMER.

(READING

SHOULD NOT

BE ABOVE

0.5 MIU)

AC Leakage Test

Summary of Contents for 46F500A

Page 28: ...28 DP33KA B a Adjust Mode OSD continued ...

Page 29: ...29 DP33KA B a Adjust Mode OSD continued ...

Page 30: ...30 DP33KA B a Adjust Mode OSD continued ...

Page 56: ...56 DP33KA B Convergence For Outside Signal function ...

Page 111: ...PRINTED CIRCUIT BOARD SIGNAL P W B PART SIDE 111 DP33KA B TABLE OF CONTENTS ...

Page 112: ...DP33KA B PRINTED CIRCUIT BOARD SIGNAL P W B PATTERN SIDE 112 ...

Page 113: ...PRINTED CIRCUIT BOARD TERMINAL P W B PART SIDE 113 DP33KA B ...

Page 114: ...PRINTED CIRCUIT BOARD TERMINAL P W B PATTERN SIDE 114 DP33KA B ...

Page 115: ...DP33KA B PRINTED CIRCUIT BOARD POWER P W B PART SIDE 115 ...

Page 116: ...PRINTED CIRCUIT BOARD POWER P W B PATTERN SIDE 116 DP33KA B ...

Page 117: ...DP33KA B PRINTED CIRCUIT BOARD DEFLECTION P W B PART SIDE 117 ...

Page 118: ...PRINTED CIRCUIT BOARD DEFLECTION P W B PATTERN SIDE 118 DP33KA B ...

Page 119: ...DP33KA B PRINTED CIRCUIT BOARD CPT P W B PART SIDE 46F500A 119 ...

Page 120: ...PRINTED CIRCUIT BOARD CPT P W B PATTERN SIDE 120 DP33KA B ...

Page 121: ...PRINTED CIRCUIT BOARD 46F510 CONTROL P W B 121 DP33KA B ...

Page 122: ...DP33KA B PRINTED CIRCUIT BOARD DVI P W B PART SIDE 122 ...

Page 123: ...PRINTED CIRCUIT BOARD DVI P W B PATTERN SIDE 123 DP33KA B ...

Page 124: ...BLOCK DIAGRAM 124 DP33KA B TABLE OF CONTENTS ...

Page 125: ...125 DP33KA B WIRING DIAGRAM TABLE OF CONTENTS ...

Page 162: ......