54

DP33KA/B

Note:

If only minor adjustments to convergence are

needed, the jig screen is not necessary. Use

digital data stored in memory and one color as a

reference (red, green, or blue). DO NOT CLEAR

DATA and WRITE to ROM memory.

2.12.4 Raster position adjustment

Adjustment preparation

(1) Position adjustment - This will move an entire

color. Use this adjustment to match colors at the

center of the screen. (Active video center from

external signal and physical screen center

should now match from phase adjustment).

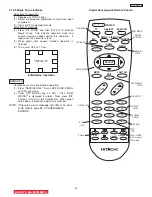

(2) Use the buttons below to switch color to adjust.

“INFO” - Green

“0” - Red

“ANT” - Blue

Adjustment procedure

(1) Press the FRZ button. Extra horizontal lines

appear to confirm raster position mode.

(2) Use the thumb stick to adjust position.

(3) Press FRZ again to exit raster position mode.

Notes:

(1) Other functions cannot be accessed when

in raster position adjustment mode. Press

FRZ and confirm extra horizontal lines

disappear to exit raster position mode.

(2) Press MENU to remove all colors displayed.

2.12.5 Convergence point adjustment

Adjustment preparation

(1) Select color to adjust.

“INFO” - Green

“0” - Red

“ANT” - Blue

(2) Use 4, 6, 2, and 5 to move the cursor position

(dotted lines).

(3) Use thumb stick to move the convergence point.

(4) Three adjustment modes are available:

1.

(3x3) Press “INFO” 5 times (only works

when DCU is in uncorrected state)

2.

(7x5) Press “0” 5 times

3.

(13x9) Press “ANT” 5 times

For touch-up, only the (13x9) mode is necessary.

This will adjust every cross-hatch intersection point

on the screen.

For complete adjustment, start with (3x3) mode. This

will adjust center point and eight edge points only,

but will greatly reduce adjustment time. Then use

(7x5) mode, and finally (13x9) mode to finish

convergence.

If “S” distortion appears between cross-hatch

lines repeat (7x5) mode to change calculation

process while adjusting to remove distortion,

then return to (13x9) mode to finish touch-up

convergence.

Adjustment procedure

(1) Receive any NTSC signal.

(2) Start adjustment at the center of the screen.

(3) Continue adjustment at next closest position.

(4) Adjust center area first, ending with edge sections.

(5) Press VID3 button to perform calculation operation.

This process will take about 1 second and no picture

will be seen at this time.

(6) After interpolation, check convergence again and

repeat (1)-(5) if necessary.

(7) When convergence is acceptable, press PIP MODE

to write data to ROM memory. ROM WRITE? is

displayed to alarm system that ROM will be

overwritten with new data. Press the PIP MODE

button again to write displayed data to ROM.

(8) DATA WRITE TO ROM will take approximately 4

seconds and no picture will be displayed.

(9) Green dots will be displayed when operation is

completed.

(10) Press MUTE to return to convergence pattern, then

confirm again convergence is acceptable.

(11) Press PIP MODE (ROM WRITE) mode, then press

SURF to initialize sensor data positions.

Notes: (1) Display only green for easier adjustment and

match to jig screen. Press “MENU”, THEN

PRESS “INFO”.

(2) Perform interpolation and data write to ROM

after green adjustment. Once green has been

confirmed to match jig screen, the jig screen can

be removed. Do not readjust the green color

after jig screen has been removed. This is now

your reference color.

(3) Display green and red only and match red to

green.

(4) Display all colors and match blue to green and

red. Touch-up red color if necessary.

(5) Existing DATA in ROM can be read by pressing

the SWAP button 2 times. This data can be used

after replacing a component (CRT, DY, etc.)

Where complete convergence adjustment is not

necessary, be careful not to overwrite this data.

DO NOT write cleared RAM data into ROM or a

complete convergence adjustment will be

necessary. Remember to try MAGIC FOCUS

before starting convergence adjustment to

minimize adjustment time.

(6) To confirm and fine tune the convergence at the

edge of the screen, press the SURF button on

the remote control while in the digital

convergence adjustment mode (DCAM) for

additional lines at the edge of the screen. Fine

tune the edge convergence as necessary. To

exit, press SURF again.

BACK TO ADJUSTMENTS

Summary of Contents for 46F500A

Page 28: ...28 DP33KA B a Adjust Mode OSD continued ...

Page 29: ...29 DP33KA B a Adjust Mode OSD continued ...

Page 30: ...30 DP33KA B a Adjust Mode OSD continued ...

Page 56: ...56 DP33KA B Convergence For Outside Signal function ...

Page 111: ...PRINTED CIRCUIT BOARD SIGNAL P W B PART SIDE 111 DP33KA B TABLE OF CONTENTS ...

Page 112: ...DP33KA B PRINTED CIRCUIT BOARD SIGNAL P W B PATTERN SIDE 112 ...

Page 113: ...PRINTED CIRCUIT BOARD TERMINAL P W B PART SIDE 113 DP33KA B ...

Page 114: ...PRINTED CIRCUIT BOARD TERMINAL P W B PATTERN SIDE 114 DP33KA B ...

Page 115: ...DP33KA B PRINTED CIRCUIT BOARD POWER P W B PART SIDE 115 ...

Page 116: ...PRINTED CIRCUIT BOARD POWER P W B PATTERN SIDE 116 DP33KA B ...

Page 117: ...DP33KA B PRINTED CIRCUIT BOARD DEFLECTION P W B PART SIDE 117 ...

Page 118: ...PRINTED CIRCUIT BOARD DEFLECTION P W B PATTERN SIDE 118 DP33KA B ...

Page 119: ...DP33KA B PRINTED CIRCUIT BOARD CPT P W B PART SIDE 46F500A 119 ...

Page 120: ...PRINTED CIRCUIT BOARD CPT P W B PATTERN SIDE 120 DP33KA B ...

Page 121: ...PRINTED CIRCUIT BOARD 46F510 CONTROL P W B 121 DP33KA B ...

Page 122: ...DP33KA B PRINTED CIRCUIT BOARD DVI P W B PART SIDE 122 ...

Page 123: ...PRINTED CIRCUIT BOARD DVI P W B PATTERN SIDE 123 DP33KA B ...

Page 124: ...BLOCK DIAGRAM 124 DP33KA B TABLE OF CONTENTS ...

Page 125: ...125 DP33KA B WIRING DIAGRAM TABLE OF CONTENTS ...

Page 162: ......