-5-

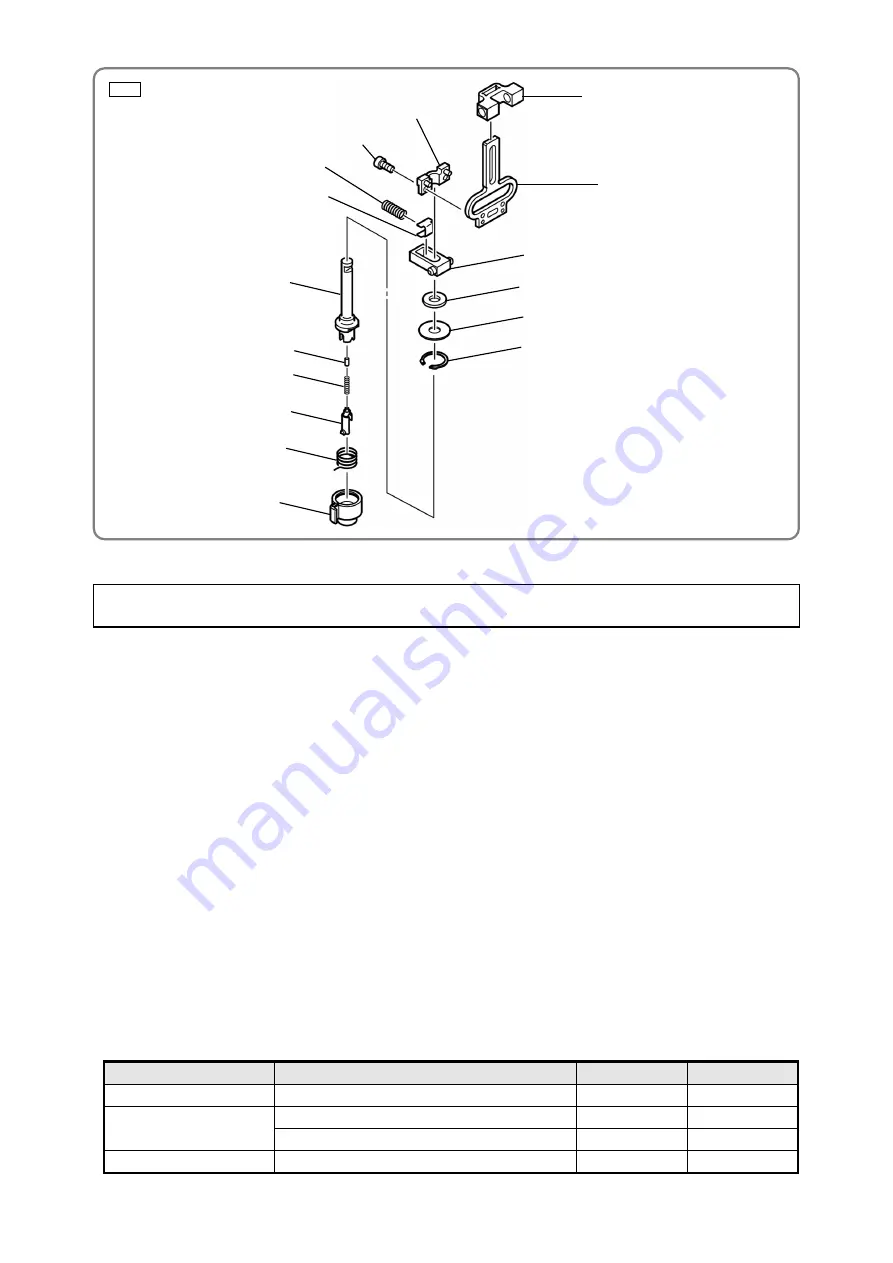

Fig. 7

Apply specified amount of grease to the following portions.

Nippeco SEP-3A grease

• Entire circumference of the Gear

[36]

, particularly its teeth

• Both sides of Washer (A)

[23]

(under the Orbital Cam

[38]

)

• Both sides and holes of the Orbital Cam

[38]

• Both sides and holes of the Balance Weight

[37]

• Outer circumference of Connecting Piece (A)

[33]

• Tooth flank of the Motor

[13]

• Outer circumference of the Steel Ball 5/32

[41]

• Entire circumference of Plunger (A)

[32]

Molub-Alloy No. 777-1 grease

• Inner diameter portion of the gear ass’y (grooves for grease and inner circumference of the needle

bearing: 0.5 g)

• Inner circumferences of Connecting Piece (A)

[33]

and Needle Bearing

[34]

(0.5 g)

• Sliding portion of the gear ass’y and the Balance Weight

[37]

Nippeco BC-4 grease

• Contact surfaces of the Spring Plate

[20]

and Plunger (B)

[25]

(0.5 g)

Please purchase the following grease as necessary.

Item

Registered part name

Net weight

Code No.

Molub-Alloy No. 777-1

Grease (Molub-Alloy No. 777-1) 75 g

75 g

325149

Nippeco SEP-3A

Grease (SEP-3A) 100 g

100 g

930035

Grease (SEP-3A) 2.5 kg 2.5

kg

930038

Nippeco BC-4

Grease (Nippeco BC-4) 75 g

75 g

372814

[31]

[17]

[32]

[18]

[25]

[19]

[26]

[20]

[29]

[27]

[30]

[28]

[21]

[24]

[22]

[23]

Lubrication points and type of lubricant