-5-

1. Safety Instructions

In the interest of promoting the safest and most efficient use of the Model M 12VE and M 12SE

Routers by all of our customers, it is very important when concluding a sale that the salesperson

carefully ensure that the buyer seriously recognizes the importance of the Handling Instructions,

and fully understands the precautions listed on the caution plate attached to each tool.

A. Handling instructions

Although every effort is made in each step of design, manufacture, and inspection to provide

protection against safety hazards, the dangers inherent in the use of any electric power tool cannot

be completely eliminated. Accordingly, the Handling Instructions list general precautions and

suggestions on the use of electric power tools, and specific precautions and suggestions on the use

of the Router to enhance the safe, efficient use of the tool by customers. Salespersons must

therefore be thoroughly familiar with the Handling Instructions in order to offer appropriate guidance

to customers during sales promotion activities.

B. Caution plate

(1) The following cautions are listed on the Name Plate attached to the main body.

[ For the USA and Canada ]

[ For Australia, New Zealand, Asia and South Africa ]

2. Special Precautions

The Handling Instructions and caution plate describe precautions on using this router. However,

salespersons should instruct customers to strictly observe the following precautions that require

special attention:

(1) Groove cutting (for a cutting depth of 20 mm or more) with a straight bit must be performed in

several times because the bit generates large recoil force during cutting.

(2) Excessively high feeding speed may not only damage the motor and/or the bit, but may also

roughly cut surfaces. A feeding speed too low may leave traces of burn on cut surfaces.

(3) The parallel or straight guide must be attached on the right side facing the feeding direction of

the router. Attaching the guide on the left side will increase the recoil force of the bit and may

result in sloppy cutting.

(4) The collet chuck must always be tightened after the bit is inserted. Tightening the collet chuck

without the bit being inserted may deform the collet chuck and disable bit insertion.

(5) After tightening the collet chuck, make sure that the lock pin returns to its original position. Using

the router with the lock pin engaged with the armature shaft may damage the lock pin and

armature shaft.

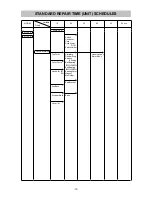

PRECAUTIONS ON SALES PROMOTION