18

English

Type of

To process crown molding at

To process crown molding at

Crown Molding

positions

1

and

4

in Fig. 25.

positions

2

and

3

in Fig. 25.

Miter Angle

Bevel Angle

Miter Angle

Bevel Angle

Setting

Setting

Setting

Setting

45° Type

right 35.3°

left 30°

right 30°

left 35.3°

left 30°

right 30°

38° Type

right 31.6°

left 33.9°

right 33.9°

left 31.6°

left 33.9°

right 33.9°

( mark)

( mark)

( mark)

( mark)

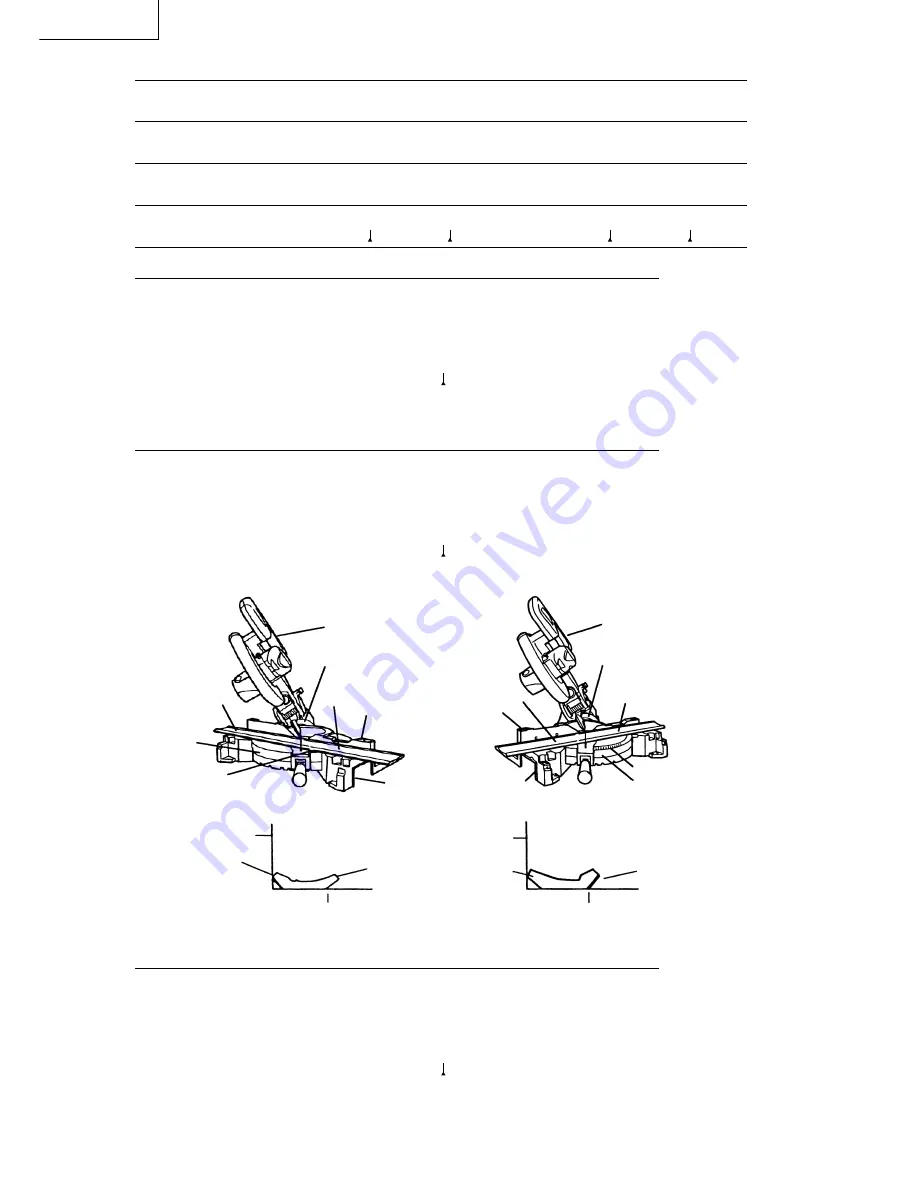

(1) Setting to cut crown moldings at positions

q

and

r

in Fig. 25 (see Fig. 26):

q

Turn the table to the right and set the Miter Angle as follows:

* For 45°

type crown moldings: 35.3°

* For 38°

type crown moldings: 31.6°

w

Tilt the head to the left and set the Bevel Angle as follows:

* For 45°

type crown moldings: 30°

* For 38°

type crown moldings: 33.9° ( mark)

e

Position the crown molding so that the upper surface (

A

in Fig. 24) contacts the fence as indicated

in Fig. 27.

(2) Setting to cut crown moldings at positions

w

and

e

in Fig. 25 (see Fig. 28):

q

Turn the table to the left and set the Miter Angle as follows:

* For 45°

type crown moldings: 35.3°

* For 38°

type crown moldings: 31.6°

w

Tilt the head to the left and set the Bevel Angle as follows:

* For 45°

type crown moldings: 30°

* For 38°

type crown moldings: 33.9° ( mark)

e

Position the crown molding so that the lower surface (

B

in Fig. 24) contacts the fence as in Fig.

29.

Fig. 26

Fig. 28

Fig. 27

Fig. 29

(3) Setting to cut crown moldings at positions

q

and

r

in Fig. 25 (see Fig. 30):

q

Turn the table to the right and set the Miter Angle as follows:

* For 45°

type crown moldings: 35.3°

* For 38°

type crown moldings: 31.6°

w

Tilt the head to the right and set the Bevel Angle as follows:

* For 45°

type crown moldings: 30°

* For 38°

type crown moldings: 33.9° ( mark)

e

Position the crown molding so that the upper surface (

B

in Fig. 24) contacts the fence as indicated

in Fig. 31.

q

Bevel

Angle Scale

r

Fence

Base

Miter Angle Scale

Table

Head

Miter Angle Scale

Bevel

Angle Scale

e

Base

Table

Head

Fence

w

Table on Base

Fence

A

B

Fence

Table on Base

B

A