--- 13 ---

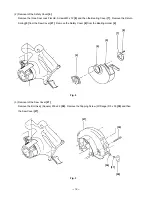

(4) Removal of the Handle Cover [45]

Remove the five Tapping Screws (W/Flange) D4 x 16 (Black) [46] to remove the Handle Cover [45].

(5) Disassembly of the Gear [1] and Motor (B) [19]

(a) Remove the Seal Lock Flat Hd. Screw M5 x 12 [3] to remove the Bearing Holder [2] and the Gear [1].

Remove the Gear [1] from the Bearing Holder [2].

(b) Remove Inner Cover (A) Ass'y [20], Inner Cover (B) [24] and Motor (B) [19] from the Housing [32].

Remove the Nylock Bolt (W/Flange) M4 x 12 [25] to remove Inner Cover (B) [24].

(c) Remove the Lock Lever [22] and the Spring [33], then remove the Ball Bearing 609VVC2PS2L [23] from

the pinion of Motor (B) [19]. Remove the two Special Bolts M5 [21] to remove Inner Cover (A) Ass'y [20].

Remove Motor (B) [19].

[20]

[21]

[22]

[19]

[23]

[1]

[2]

[3]

[33]

[32]

[24]

[25]

Fig. 4

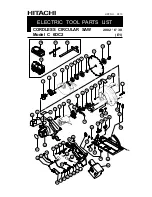

Summary of Contents for C 6DC2

Page 27: ......