--- 4 ---

HITACHI

C --- 1

HITACHI

C --- 2

C 6SF/C 6MF

C 7SF/C 7MF

165 (6-1/2")

160 (6-1/4")

190 (7-1/2")

185 (7-1/4")

57 (2-1/4")

55 (2-5/32")

68 (2-11/16")

66 (2-19/32")

38 (1-1/2")

36 (1-3/8")

46 (1-13/16")

44 (1-23/32")

1,010

950

1,050

1,050

5,000

4,700

5,000

4,700

270/282

268

282/295

282

3.0 (6.6 lbs)

3.3 (7.3 lbs)

3.3 (7.3 lbs)

3.7 (8.2 lbs)

5,400

5,400

5,530

5,130

4,070

3,660

4,000

3,330

550

545

590

700

1,500

1,340

1,500

1,500

84

82

84

84

Provided

None

Provided

None

Steel/Aluminum

Steel

Steel/Aluminum

Steel

Plastic

Steel

Plastic

Steel

Plastic

Steel

Plastic

Steel

270/282

268

282/295

282

229

230

242

240

210

225

210

230

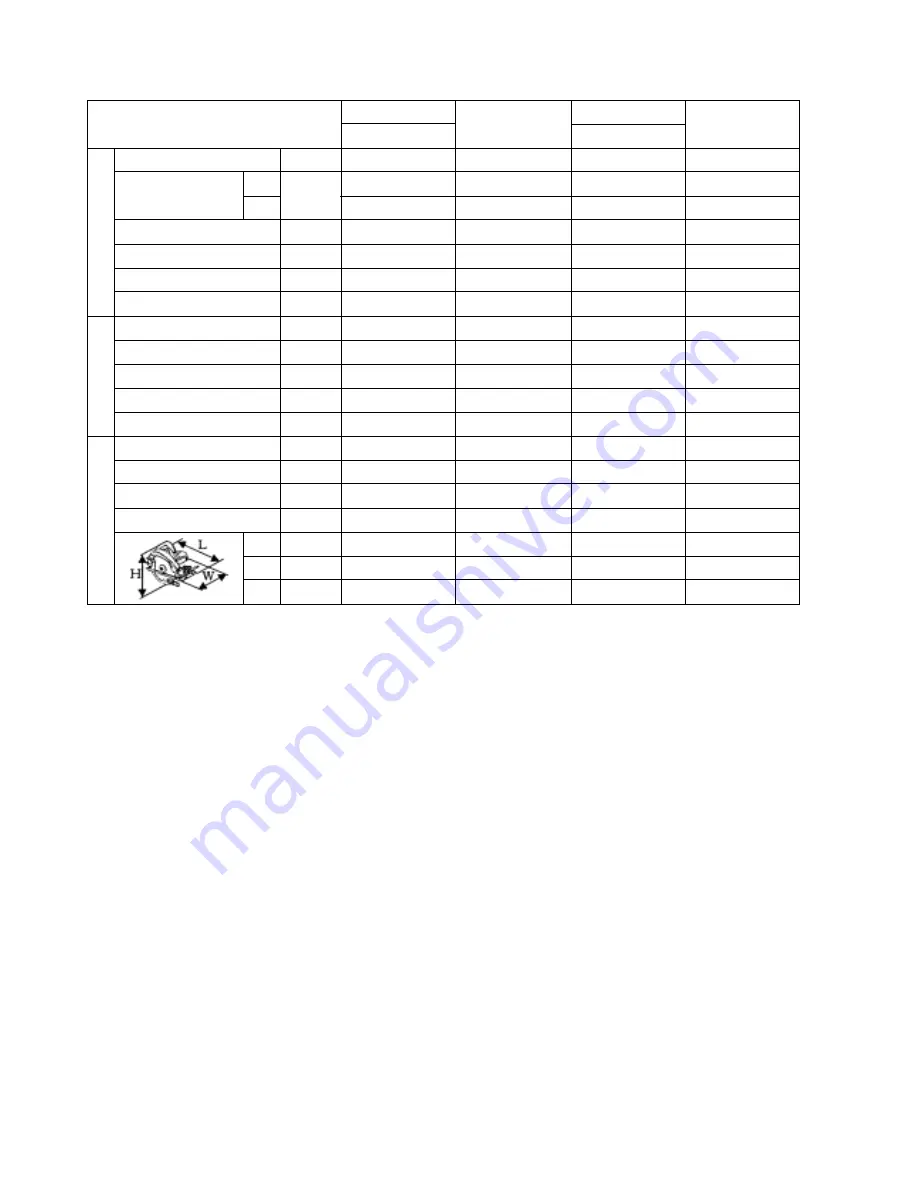

Maker

Model

Saw blade diameter

mm

Max. cutting

90˚

depth

45˚

Power input

W

No-load rotation speed

/min

Overall length

mm

Weight

kg

No-load rotation speed

/min

Full-load rotation speed

/min

Full-load output

W

Max. output

W

No-load noise

dB

Palallel adjustment

---

Material of base

---

Material of lower guard

---

Material of wing bolt/nut

---

L

mm

H

mm

W

mm

6. COMPARISONS WITH SIMILAR PRODUCTS

Catalog specifications

Characteristics*

Structure

7. PRECAUTIONS IN SALES PROMOTION

In the interest of promoting the safest and most efficient use of the Models C 6SF, C 6MF, C 7SF and C 7MF

Circular Saws by all of our customers, it is very important that at the time of sale the salesperson carefully

ensures that the buyer seriously recognizes the importance of the contents of the Handling Instructions.

7-1. Handling Instructions

Although every effort is made in each step of design, manufacture, and inspection to provide protection against

safety hazards, the dangers inherent in the use of any electric tool cannot be completely eliminated. Accordingly,

general precautions and suggestions for the use of electric power tools, and specific precautions and suggestions

for the use of the circular saw are listed in the Handling Instructions to enhance the safe and efficient use of the

tool by the customer. Salespersons must be thoroughly familiar with the contents of the Handling Instructions to

be able to offer appropriate guidance to the customer during sales promotion.

* Figures are based on 230 V motors

mm

Summary of Contents for C 6MF

Page 32: ......