--- 14 ---

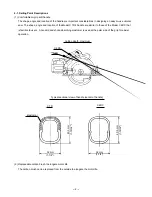

(4) Reassembly of the Bearing Holder [9] with the Spindle and Gear Set [8]

It becomes difficult to mount both the Bearing Holder [9] and the Spindle and Gear Set [8] to the Gear Cover

Ass'y [3] if grease gets in the metal chamber of the Gear Cover Ass'y [3]. Very lightly apply grease on the

metal sliding surface of the spindle being careful not to get grease in the metal chamber. If reassembly is still

difficult, push in the spindle turning laterally. Never tap the end of the spindle with a hammer. Otherwise the

Gear Cover Ass'y [3] may be damaged.

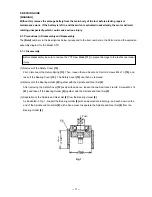

(5) Mounting the Magnet [40]

Mount the Magnet [40] to the Housing [34] aligning the notch at the outer circumference of the Magnet [40]

with the protrusion inside the Housing [34].

(6) Lubrication

Liberally apply the designated lubricants as follows.

Nippeco SEP-3A (Code No. 930035) within the gear cover: 8 to 9 gr. (0.282 to 0.317 oz)

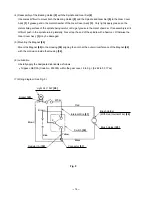

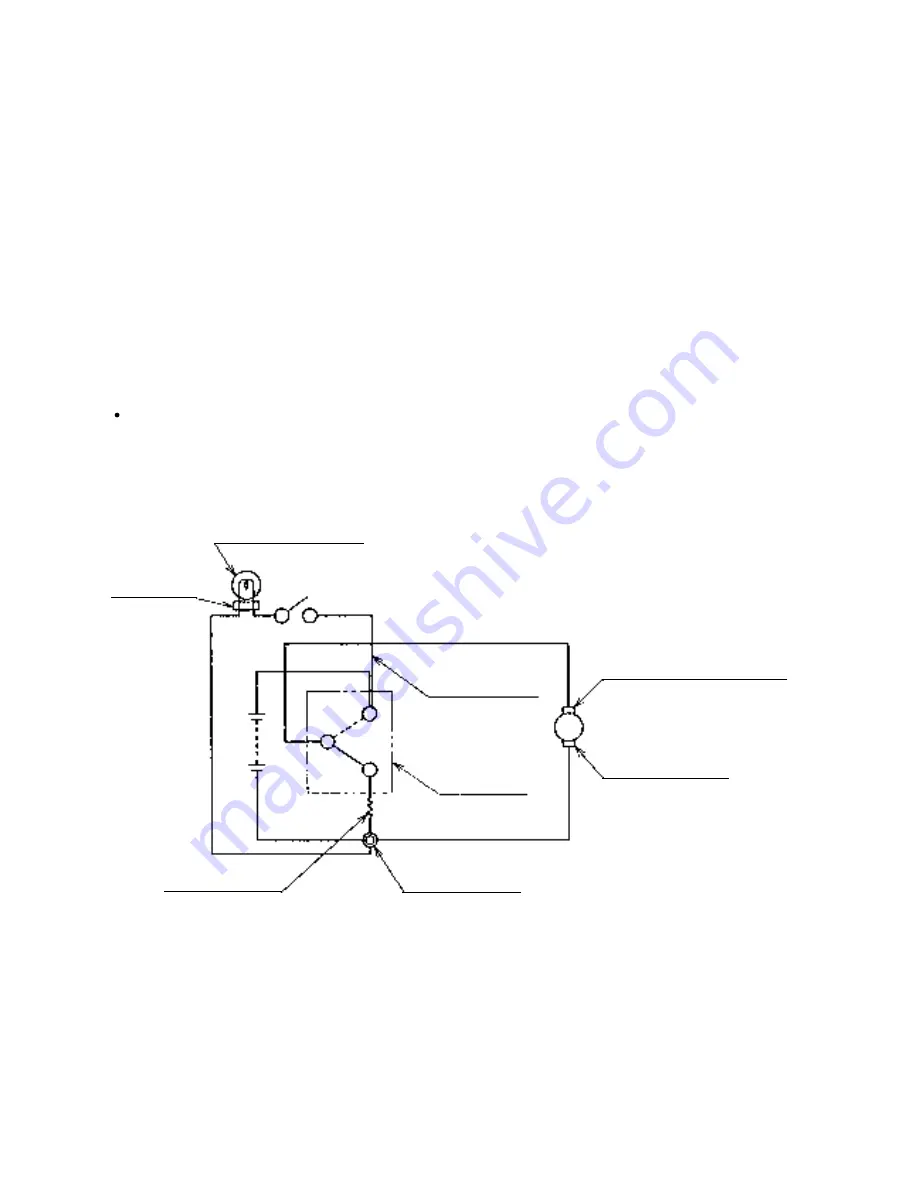

(7) Wiring diagram (See Fig. 5.)

Switch [30]

Socket [25]

Brush Holder [29]

Brush Holder

(With Red Internal Wire) [48]

Resistor (A) [39]

Connector [51]

Light 24 V 5 W [26]

Internal Wire [31]

Black

Fig. 5

Brown

Yellow

Brown

Blue

White

Red

3

2

1

Summary of Contents for C 7D

Page 25: ......