--- 12 ---

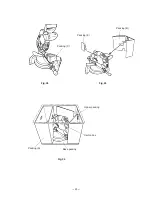

The laser line is adjusted to the width of the saw blade at the time

of factory shipment. Depending upon the cutting choice, align the

laser line with the left side of the cutting width (saw blade) or the

right side according to the following procedure. First, make a

right-angle ink line on the workpiece that is about 38 mm (1-1/2")

in height and 89 mm (3-1/2") in width. To cut the right side of the

ink line with the saw blade as shown in Fig. 11, align the left side

of the saw blade with the ink line on the workpiece and make a

groove of about 5 mm deep on the workpiece to the middle. Hold

the grooved workpiece by the vise as it is and do not move it.

Light up the laser marker. Then insert a 4 mm hex. bar wrench in

the 12 diameter hole on the side of the gear case, turn the hex.

socket set screw to move the laser line. (If you turn the hex.

socket screw clockwise, the laser line will shift to the right and if

you turn it counterclockwise, the laser line will shift to the left.)

(Fig. 10)

Thus the cutting position matches the laser line position. Align the

ink line on the workpiece with the laser line. When aligning the

ink line, slide the workpiece little by little and secure it by vise at a

position where the laser line overlaps with the ink line (Fig. 11).

Work on the grooving again and check the position of the laser

line. When the ink line and the laser line are overlapped, the

strength and weakness of light will change, resulting in a stable

cutting operation because you can easily discern the conformity of

lines. This ensures the minimum cutting errors.

Ink line

Saw blade

Fig. 9

WARNING:

Make sure before plugging the power plug into the receptacle that the main body and the laser

marker are turned off.

Exercise utmost caution in handling a switch trigger for the position adjustment of the laser line, as

the power plug is plugged into the receptacle during operation. If the switch trigger is pulled

inadvertently, the saw blade can rotate and result in unexpected accidents.

Do not remove the laser marker to be used for other purposes.

Workpiece

Cutting width

Move

4 mm hex.

bar wrench

Fig. 10

Laser line

Turn

Ink line

Laser line

Fig. 11

Groove

8. ADJUSTMENT AND OPERATION PRECAUTIONS

8-1. Position Adjustment of Laser Line (Models C 12LCH/C 12FCH)

Summary of Contents for C12FCH

Page 39: ... 35 Wiring diagram C 12LCH Fig 38 2 ...

Page 40: ... 36 C 12LCH Europe AUS NZL China Fig 39 1 Fig 39 2 ...

Page 41: ... 37 Fig 40 2 Wiring diagram C 12LC USA CAN Fig 40 1 ...

Page 42: ... 38 C 12LC Europe NZL Fig 41 1 Fig 41 2 ...

Page 43: ... 39 Fig 42 2 Wiring diagram C 12FCH USA CAN Fig 42 1 ...

Page 44: ... 40 C 12FCH Europe NZL Asia Fig 43 1 Fig 43 2 ...

Page 76: ... 10 ITEM NO CODE NO DESCRIPTION REMARKS NO USED 6 05 C 12LC Printed in Japan 050630N ...

Page 86: ... 10 ITEM NO CODE NO DESCRIPTION REMARKS NO USED 6 05 C 12FCH Printed in Japan 050630N ...

Page 87: ......