--- 5 ---

1.6 (1/16")

1.2 (3/64")

2.0 (5/64")

30 (1-3/16")

300

4,000

1.7 (3.7 lbs.)

160

2700

2

Throw away

(8 edges)

Provided

80

112

200

230

146

7-7/8"

9-1/16"

5-3/4"

1.6 (1/16")

1.2 (3/64")

2.3 (3/32")

25 (63/64")

400

4,200

1.8 (4 lbs.)

220

2800

2

Throw away

(8 edges)

Provided

79

108

208

258

146

8-3/16"

10-5/32"

5-3/4"

HITACHI

1.6 (1/16")

1.2 (3/64")

2.3 (3/32")

25 (63/64")

400

4,700

1.7 (3.7 lbs.)

230

2900

2

Throw away

(8 edges)

Provided

79

108

184

250

146

7-1/4"

9-27/32"

5-3/4"

Maker

•

Model

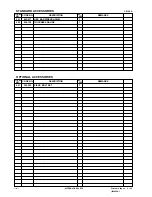

6. COMPARISONS WITH SIMILAR PRODUCTS

The specifications of the Model CE 16SA are compared with various other models in the table below. The primary

advantages of the Model CE 16SA in comparison with the other models are:

(1) Smallest grip and lightweight design

(2) Rapid cutting speed

(3) Powerful motor

(4) Throw-away blade that requires minimal maintenance

Unit

Item

Mild steel

Capacity

Nameplate and catalog

specifications

CE 16SA

CE 16

Aluminum plate

Stainless steel

mm

mm

mm

mm

W

min

-1

kg

W

min

-1

mm

Min. cutting radius

Power input

No-load stroke

Weight

Power output

Full-load stroke

Length of stroke

Type of blade

Scrap guide

No-load noise level 1 m

No-load vibration

Characteristics

dB

dB

mm

D

L

H

inch

D

L

H

External dimensions

B

C

1.6 (1/16")

0.7 (1/32")

2.0 (5/64")

20 (51/64")

350

2,200

1.9 (4.2 lbs.)

Throw away

(4 edges)

Provided

79

107

195

289

140

7-11/16"

11-3/8"

5-33/64"

Thickness gauge

Hex. bar wrench

1

1

1

1

1

1

1

H

L

Grip circumference D

Standard

accessories

Summary of Contents for CE 16SA

Page 21: ......