6

NOTE

When it is hard to insert drive shaft up to the marked position on

the drive shaft tube, turn drive shaft by the cutter mounting end

clockwise or counter-clockwise. Tighten tube locking bolt lining

up the hole in the shaft tube. Then tighten clamp bolt securely.

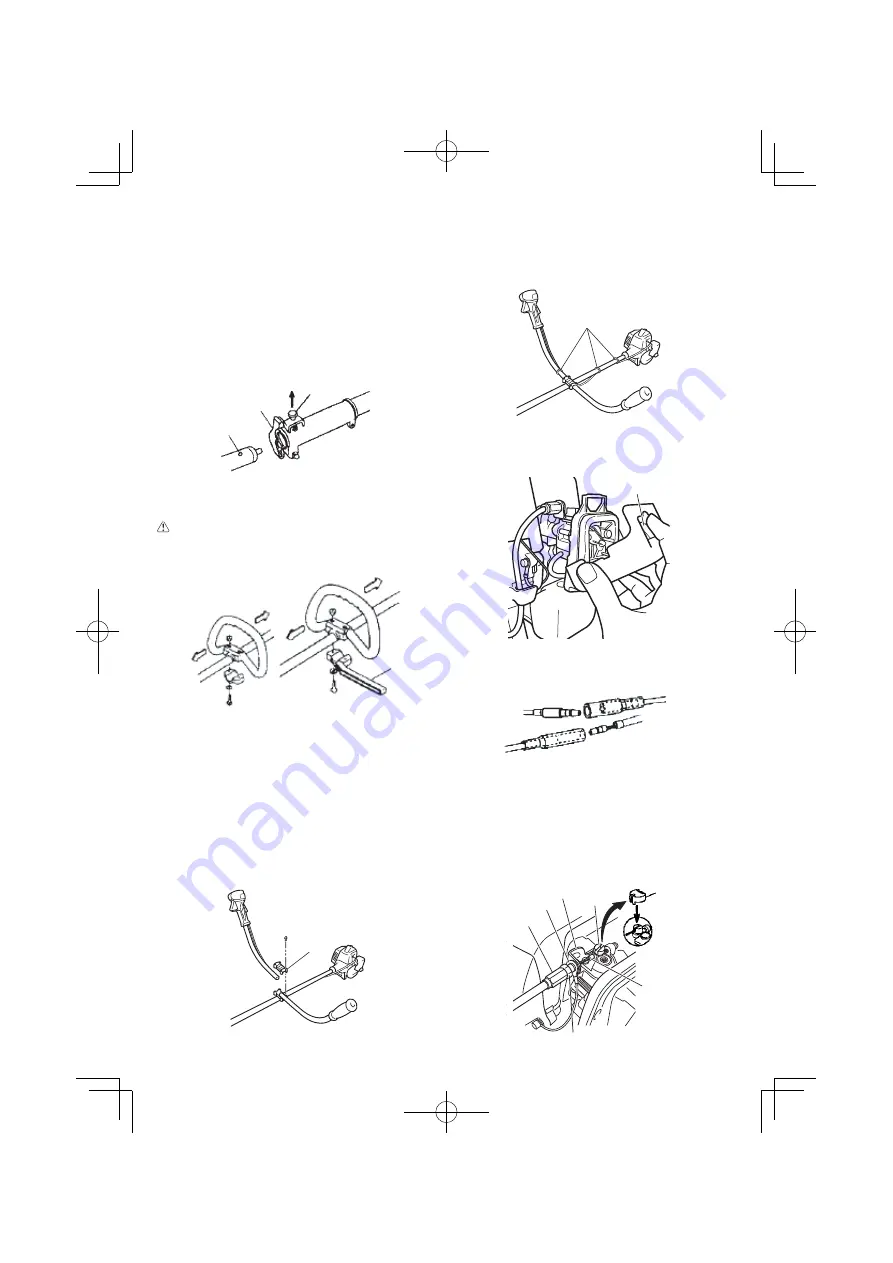

Installation

of

attachment

1. Join the attachment in place of it.

2. Make sure the lock pin (3)

fi

ts in the location hole (4) of tube and

that the tube will not come o

ff

. (

Fig.

2

)

3. Tighten the knob nut (5) securely. (

Fig.

2

)

3

5

4

Fig.

2

Installation

of

handle

WARNING

When you use steel/rigid blades on straight shaft trimmers or

brush cutters, always use a barrier bar (6) and shoulder harness

with the loop handle. (

Fig.

3

)

6

Fig.

3

Attach the handle to the drive shaft tube with the angle towards the

engine.

Adjust the location to the most comfortable position before

operation.

NOTE

If your unit has handle location label on drive shaft tube, follow

the illustration.

Remove the handle bracket (7) from the assembly. (

Fig.

4

)

Place the handles and attach the handle bracket with four bolts

lightly. Adjust to appropriate position. Then attach it

fi

rmly with the

bolts.

7

Fig.

4

Attach the protection tube to the drive shaft or handle using cord

clamps (8). (

Fig.

5

)

8

Fig.

5

Throttle

wire

/

stop

cord

Press the upper tab (9) and open the air cleaner cover. (

Fig.

6

)

9

Fig.

6

Connect stop cords. (

Fig.

7

)

Fig.

7

If the throttle outer end (10) is threaded on your unit, screw it and the

earth terminal (11) (if so equipped) into the cable adjuster stay (12)

all the way, and then tighten this cable end using the adjuster nut

(13) against the cable adjuster stay (12).

Connect throttle wire end (14) to carburetor (15) and install swivel

cap (16) (if so equipped) where is included in tool bag, onto swivel

(15) (

Fig.

8

).

Some models may come with the parts installed.

15

13

16

12

11

10

14

Fig.

8

000Book̲CG22EAS̲Eng.indb 6

000Book̲CG22EAS̲Eng.indb 6

2010/01/18 17:16:09

2010/01/18 17:16:09