8

○

For outstanding performance and reliability, always use Hitachi

nylon cutting line. Never use wire or other materials that could

become a dangerous projectile.

○

If the cutting head does not feed cutting line properly, check

that the nylon line and all components are properly installed.

Contact your Hitachi dealer if you need assistance.

3. Installation

(

Fig.

14

)

○

Install cutting head on gear case of grass trimmers/brush

cutters. The mounting nut is left-hand-threaded. Turn clockwise

to loosen/counterclockwise to tighten.

19

Fig.

14

For curved shaft models, the mounting nut is right-hand-threaded.

Turn counterclockwise to loosen/clockwise to tighten.

NOTE

○

Since the cutter holder cap is not used here, keep it for when a

metal blade is used, if so equipped.

○

Insert Allen wrench (19) into the hole of the gear case in order to

lock the cutter holder.

4. Adjusting line length

○

Set the engine speed as low as possible and tap the head on

the ground. The nylon line will be drawn out about 3 cm with

each tap. (

Fig.

15

)

Fig.

15

Also, you can extend the nylon line by hand but the engine must

be completely stopped. (

Fig.

16

)

Fig.

16

○

Adjust the nylon line to the proper length of 11–14 cm before

each operation.

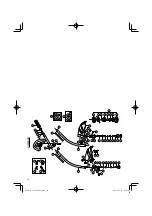

Installation

of

cutting

blade

(

Fig.

17

)

(If so equipped)

When installing a cutting blade, make sure that there are no cracks

or any damage in it and that the cutting edges are facing the correct

direction.

21

20

22

23

19

Fig.

17

NOTE

○

When installing cutter holder cap (20), be sure to set concave

side upward.

○

Insert the alien wrench (19) into the hole of the angle

transmission in order to lock the cutter holder (21). Please note

that the cutter

fi

xing bolt or nut (22) has left-handed threads,

(clockwise to loosen/ counter-clockwise to tighten). Tighten the

fi

xing bolt or nut with the box wrench.

○

If your unit is of a nut securing type and equipped with a cotter

pin, the blade must be retained with a new pin (23) each time

installed. (

Fig.

18

)

23

Fig.

18

CAUTION

○

Before operation, make sure the blade has been properly

installed.

○

If your unit is equipped with protection cover under a cutting

blade, check it for wear or cracks before operation. If any damage

or wear is found, replace it, as it is an article of consumption.

WARNING

For Hitachi heads, use only

fl

exible, non-metallic line

recommended by the manufacturer. Never use wire or wire

ropes. They can break o

ff

and become a dangerous projectile.

OPERATING

PROCEDURES

Fuel

(

Fig.

19

)

WARNING

○

The trimmer is equipped with a two-stroke engine. Always run

the engine on fuel, which is mixed with oil.

Provide good ventilation, when fueling or handling fuel.

○

Fuel contains highly

fl

ammable and it is possible to get the

serious personal injury when inhaling or spilling on your body.

Always pay attention when handling fuel. Always have good

ventilation when handling fuel inside building.

000Book̲CG22EAS̲Eng.indb 8

000Book̲CG22EAS̲Eng.indb 8

2010/01/18 17:16:09

2010/01/18 17:16:09