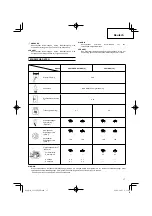

12

English

Carburetor

adjustment

(

Fig.

29

)

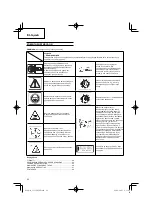

WARNING

○

The cutting attachment may be spinning during carburetor

adjustments.

○

Never start the engine without the complete clutch cover and

tube assembled! Otherwise the clutch can come loose and

cause personal injuries.

In the carburetor, fuel is mixed with air. When the engine is test

run at the factory, the carburetor is basically adjusted. A further

adjustment may be required, according to climate and altitude. The

carburetor has one adjustment possibility:

T

=

Idle

speed

adjustment

screw.

Idle

speed

adjustment

(

T

)

Check that the air

fi

lter is clean. When the idle speed is correct, the

cutting attachment will not rotate. If adjustment is required, close

(clockwise) the T-screw, with the engine running, until the cutting

attachment starts to rotate. Open (counter-clockwise) the screw

until the cutting attachment stops. You have reached the correct idle

speed when the engine runs smoothly in all positions well below the

rpm when the cutting attachment starts to rotate.

If the cutting attachment still rotates after idle speed adjustment,

contact your Hitachi dealer.

NOTE

Standard Idle rpm is 2200–2800 rpm.

WARNING

When the engine is idling the cutting attachment must under no

circumstances rotate.

Air

fi

lter

(

Fig.

30

)

The air

fi

lter must be cleaned from dust and dirt in order to avoid:

○

Carburetor

malfunctions

○

Starting

problems

○

Engine power reduction

○

Unnecessary wear on the engine parts

○

Abnormal fuel consumption

Clean the air

fi

lter daily or more often if working in exceptionally

dusty areas.

Cleaning

the

air

fi

lter

Remove the air

fi

lter cover and the

fi

lter (19). Rinse it in warm soap

suds. Check that the

fi

lter is dry before reassembly. An air

fi

lter

that has been used for some time cannot be cleaned completely.

Therefore, it must regularly be replaced with a new one. A damaged

fi

lter must always be replaced.

Fuel

fi

lter

(

Fig.

31

)

Drain all fuel from fuel tank and pull fuel

fi

lter line from tank. Pull

fi

lter element out of holder assembly and rinse element in warm

water with detergent.

Rinse thoroughly until all traces of detergent are eliminated.

Squeeze, do not wring, away excess water and allow element to air

dry.

NOTE

If element is hard due to excessive dirt buildup, replace it.

Spark

plug

(

Fig.

32

)

The spark plug condition is in

fl

uenced by:

○

An incorrect carburetor setting

○

Wrong fuel mixture (too much oil in the gasoline)

○

A dirty air

fi

lter

○

Hard running conditions (such as cold weather)

These factors cause deposits on the spark plug electrodes, which

may result in malfunction and starting di

ffi

culties. If the engine

is low on power, di

ffi

cult to start or runs poorly at idling speed,

always check the spark plug

fi

rst. If the spark plug is dirty, clean it

and check the electrode gap. Re-adjust if necessary. The correct

gap is 0.6 mm. The spark plug should be replaced after about 100

operation hours or earlier if the electrodes are badly eroded.

Mu

ffl

er

(

Fig.

33

)

Remove the mu

ffl

er and clean out any excess carbon from the

exhaust port or mu

ffl

er inlet every 100 hours of operation.

Cylinder

(

Engine

cooling

) (

Fig.

34

)

The engine is air cooled, and air must circulate freely around engine

and over cooling

fi

ns on cylinder head to prevent overheating.

Every 100 operating hours, or once a year (more often if conditions

require), clean

fi

ns and external surfaces of engine of dust, dirt and

oil deposits which can contribute to improper cooling.

NOTE

Do not operate engine with engine shroud or mu

ffl

er guard

removed as this will cause overheating and engine damage.

Angle

transmission

(

Fig.

35

)

Check angle transmission or angle gear for grease level about every

50 hours of operation by removing the grease

fi

ller plug on the side

of angle transmission.

If no grease can be seen on the

fl

anks of the gears,

fi

ll the

transmission with quality lithium based multipurpose grease up to

3/4. Do not completely

fi

ll the transmission.

Blade

WARNING

Wear protective gloves when handling or performing

maintenance on the blade. (

Fig.

36

)

○

Use a sharp blade. A dull blade is more likely to snag and thrust.

Replace the fastening nut if it is damaged and hard to tighten.

○

When replacing blade, purchase one recommended by Hitachi,

with a 25.4 mm (one inch)

fi

tting hole.

○

When installing a saw blade, always face the stamped side up.

In the case of a 3 tooth blade, it can be used on either side.

○

Use the correct blade for the type of work.

○

When replacing blades, use appropriate tools.

○

When cutting edges become dull, re-sharpen or

fi

le as shown

in the illustration. Incorrect sharpening may cause excessive

vibration.

○

Discard blades that are bent, warped, cracked, broken or

damaged in any way.

NOTE

When sharpening blade it is important to maintain an original

shape of radius at the base of the tooth to avoid cracking.

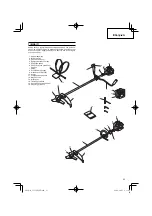

Nylon

head

Nylon line replacement

○

Remove the cutting body cap by pushing inward the locking

tabs on the side of the nylon head (

Fig.

37

). Take out the spool

(

Fig.

38

), hook the new nylon line into the hole of the spool, then

wind it around the spool in two stages (

Fig.

39

).

When the nylon line has been wound around the spool,

temporarily fasten it in the opening of the spool at about 10 cm

from the end. (

Fig.

40

) Then thread the nylon line through the

hole on the side of the nylon head and place the cutting body

cap in reverse order of the cap removal. Pull the right and left

nylon lines until they are secured about 15

–

16 cm from the end.

(

Fig.

42

)

NOTE

○

The nylon head is designed for nylon lines with an outer

diameter of 2.5 mm. Do not use nylon lines with a di

ff

erent outer

diameter.

○

Make sure that the right and left nylon lines are of equal length

since vibrations will otherwise increase.

Maintenance

schedule

Below you will

fi

nd some general maintenance instructions. For

further information please contact your Hitachi dealer.

Daily

maintenance

○

Clean the exterior of the unit.

○

Check that the harness is undamaged.

○

Check the blade guard for damage or cracks. Change the guard

in case of impacts or cracks.

000Book̲CG31EBS̲EE.indb 12

000Book̲CG31EBS̲EE.indb 12

2009/10/15 9:13:39

2009/10/15 9:13:39