9

English

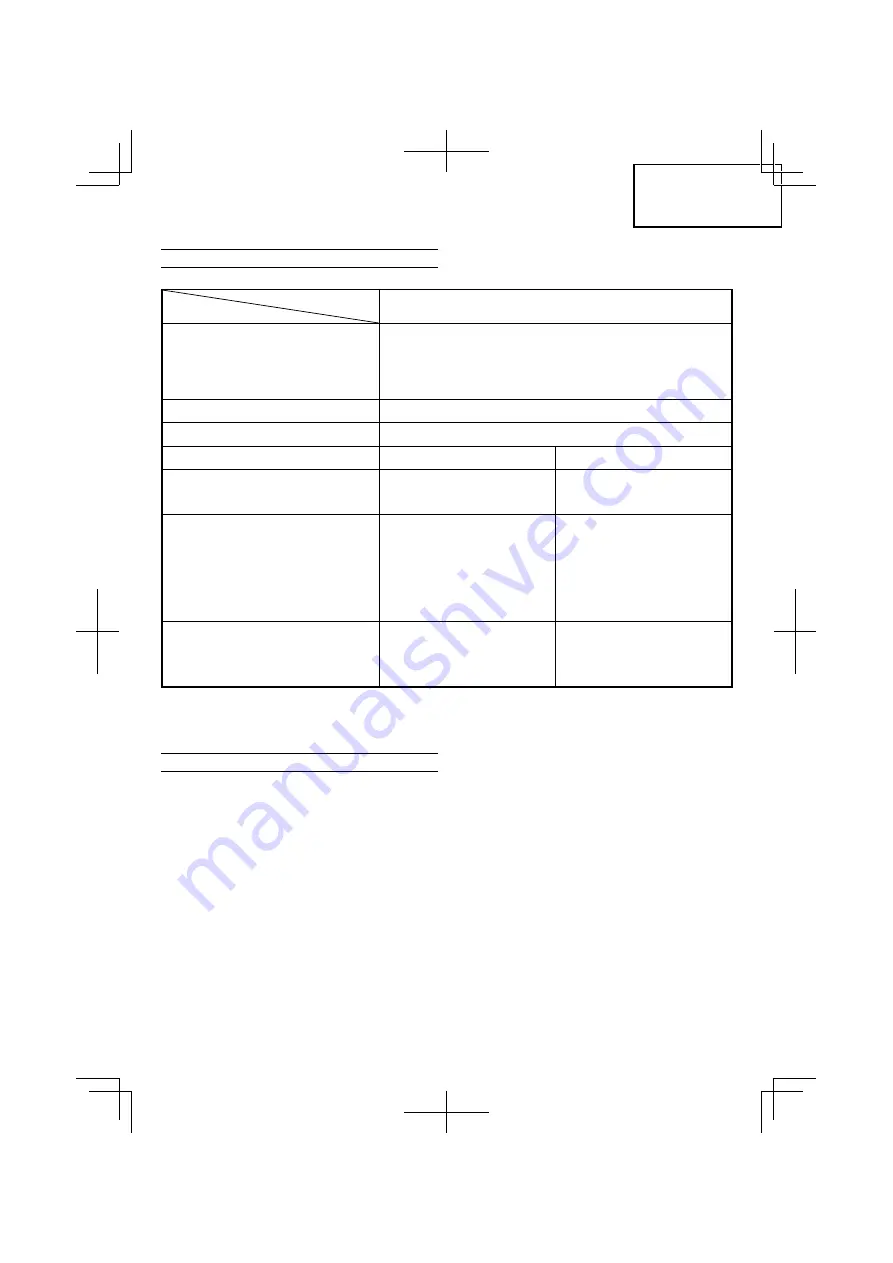

SPECIFICATIONS

Model

CG40EAS / CG40EAS (P)

Engine

Displacement (cm

3

)

Spark plug

Idling speed (min

-1

)

Speed of output shaft (min

-1

)

Max. engine output (kW)

39,8

NGK BPMR6A

2500

―

3000

9100

1.31

Fuel tank capacity (cm

3

)

1000

Dry weight (kg)

7.6

Cutting attachment

Type / Dia. (mm)

Nylon cord

Metal blade / 255

Sound pressure

level LpA

(dB (A))

(ISO22868)

Equivalent

Uncertainty

86

3

84

3

Measured sound

power level LwA

(dB (A))

Measured sound

power level LwA (dB (A))

Guaranteed sound

power level LwA (dB (A))

(ISO22868)

Racing

Uncertainty

(2000/14/EC)

Racing

(2000/14/EC)

Racing

108

3

108

110

107

3

107

109

Vibration level (m/s

2

) (ISO22867)

Equivalent (Front / Left handle)

Equivalent (Rear / Right handle)

Uncertainty

3.2

2.8

1.5

4.6

4.5

1.5

NOTE

Equivalent noise level/vibration level are calculated as the time-weighted energy total for noise/vibration levels under various working

conditions with the following time distribution: 1/2 Idle, 1/2 racing.

* All data is subject to change without notice.

ASSEMBLY PROCEDURES

Drive shaft to engine (Fig. 1)

Loosen tube locking bolt (1) about ten turns so that the bolt point will

not obstruct drive shaft tube to be inserted. When inserting drive

shaft tube, hold the tube locking bolt outward preventing inside

fi

tting from obstructing as well.

Insert the drive shaft into the clutch case of the engine properly on

the drive shaft tube meets the clutch case.

Some models may come with the drive shaft already installed.

NOTE

When it is hard to insert drive shaft up to the marked position on

the drive shaft tube, turn drive shaft by the cutter mounting end

clockwise or counter-clockwise. Tighten tube locking bolt lining

up the hole in the shaft tube. Then tighten clamp bolt securely

(1).

Installation of handle

Remove the handle bracket (2) from the assembly. (

Fig. 2

)

Place the handles and attach the handle bracket with four bolts

lightly. Adjust to appropriate position. Then attach it

fi

rmly with the

bolts.

Attach the protection tube to the drive shaft or handle using cord

clamps (3). (

Fig. 3

)

NOTE

If the protection tube is set apart from the handle or pipe, it will

be caught by something during operation and it may cause

serious injury. Do not set the protection tube apart from the

handle or pipe.

Throttle wire / stop cord

Remove air cleaner cover. (

Fig. 4

)

Connect stop cords. (

Fig. 5

)

Insert the stay (4) under the nut (5) screwed onto the outer end of

the throttle wire (6) and connect the end of the throttle wire (7) to the

carburetor (8). Then tighten the nut (5) to secure the throttle wire to

the stay (4). (

Fig. 6

)

NOTE

Check that the carburetor throttle returns to the idle position

and also that it can be opened wide by operating the throttle

lever.

Cover throttle wire and stop cords together with protective tube

provided up to air cleaner cover. (

Fig. 7

)

Some models may come with the drive shaft already installed.

000Book̲CG40EAS̲EE.indb 9

000Book̲CG40EAS̲EE.indb 9

2014/07/01 9:30:08

2014/07/01 9:30:08