5

English

STANDARD ACCESSORIES

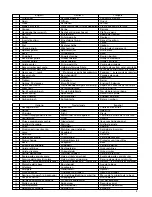

(1) Blades (No. 41, No. 42, No. 46) ................ 1 each

Refer to

Table 1

for use of the blades.

(2) Hexagon bar wrench ............................................... 1

(3) Splinter guard ........................................................... 1

Standard accessories are subject to change without notice.

OPTIONAL ACCESSORIES ... Sold separately

(1) Various types of blades

Refer to

Table 1

for use of the blades.

(2) Dust collecter

(3) Rectilinear guide

(4) Circular guide

(5) Bench stand (Model TR12-B)

Optional accessories are subject to change without notice.

APPLICATIONS

䡬

Cutting various lumber and pocket cutting

䡬

Cutting mild steel plate, aluminum plate, and copper

plate

䡬

Cutting synthetic resins, such as phenol resin and

vinyl chloride

䡬

Cutting thin and soft construction materials

䡬

Cutting stainless steel plate (with No. 95, No. 96

or No. 97 blade).

PRIOR TO OPPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specified on the product

nameplate.

2. Power switch

Ensure that the power switch is in the OFF position.

If the plug is connected to a receptacle while the

power switch is in the ON position, the power tool

will start operating immediately, which could cause

a serious accident.

3. Extension cord

When the work area is removed from the power

source, use an extension cord of sufficient thickness

and rated capacity. The extension cord should be

kept as short as practicable.

4. Mounting the blade

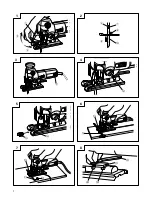

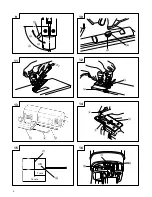

(1) Open the chip cover. (

Fig. 1

)

(2) Use the accessory hexagonal bar wrench to loosen

the blade set screw on the set ring, as shown in

Fig. 2

.

(3) Fully insert the blade mounting portion into the set

ring with the rear face of the blade engaged with

the groove and tighten the set screw. (

Fig. 2

).

(4) Close the chip cover. (

Fig. 1

).

NOTE:

Loosened set screw may cause the blade to be

damaged. Always ensure that the set screw is

securely tightened. Always ensure that the mounting

portion of the set ring is clean and claer of sawdust

to ensure proper blade mounting and set screw

clamping.

5. Adjusting the blade operating speed

The CJ110VA is equipped with the electric control

circuit which enables stepless speed control. To

adjust the speed, turn the dial shown in

Fig. 3

.

When the dial is set to “1”, the jig saw operates

at the minimum speed (700 /min). When the dial

set to “5”, the jig saw operates at the maximum

speed (3200 /min). Adjust the speed according to

the material to be cut and working efficiency.

CAUTION

At low speed (dial setting: 1 or 2) do not cut a wood

with a thickness of more than 10 mm or metal with

a thickness of more than 1 mm.

6. Adjusting the orbital operation

(1) This machine employs orbital operation which moves

the blade back and forth, as well as up and down.

Set the change knob shown in

Fig. 4

to “0” to

eliminate the orbital operation (the blade moves

only up and down). The orbital operation can be

selected in 4 steps from “0” to “III”.

(2) For the hard material, such as a steel plate, etc.,

decrease the o3rbital operation. For the soft material,

such as lumber, plastic, etc., increase the orbital

operation to increase work efficiency. To cut the

material accurately, decrease the orbital operation.

7. Cutting stainless steel plates

The CJ110VA model, when used with the No. 95,

No. 96 or No. 97 blade, can cut stainless steel

plates. Carefully read “Concerning cutting of stainless

steel plates” for proper operation.

8. Splinter guard

Using the splinter guard when cutting wood

materials will reduce splintering of cut surfaces.

Insert the splinter guard in the space between the

base and sub-base, push forward and attach (see

Fig. 5

).

SPECIFICATIONS

Voltage (by areas)*

(110V, 115V, 120V, 127V, 220V, 230V, 240V)

Power Input*

570W

Max. Cutting Depth

Wood 100 mm

Mild Steel 10 mm

No-Load Speed

700—3200/min.

Stroke

26 mm

Min. Cutting Radius

25 mm

Weight (without cord)

2.4kg

*Be sure to check the nameplate on product as it is subject to change by areas.