English

36

CAUTION

If the spacers are not attached or if spacers of the

wrong size are used, the threads of the cutter and

the studs will not properly mesh, thereby causing

damage to the studs and the cutter edge. Be sure

to attach spacers correctly.

2

When using the W3/8" cutter

No spacers are required. Check and confirm that

only the cutter is attached.

For details, refer to the section on “Cutter life and

replacement” on page 38.

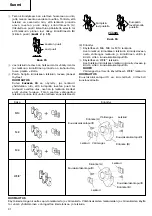

7. Correctly insert the stud guide.

The stud guide is used to prevent tilting during

cutting of studs. Correctly adjust the dial calibration

to the mark ( ) depending on the size of the stud

to be cut (

Fig. 3

).

CAUTION

If the size of the stud and the dial position to do

not agree, the cut section may be subjected to burrs

or its shape may be distorted, which may result in

damage to the main unit.

Fig. 3

8. Check plug receptacle.

If a receptacle jounces or a plug comes out easily

when a power cord is plugged in, the receptacle

needs to be repaired. Consult the nearest electric

service station for repair. Continued use of the

defective receptacle can result in overheating and

accidents.

HOW TO USE

CAUTIONS

䡬

Never bring the cutter near your fingers when

operating the trigger switch.

䡬

When cutting short studs, take caution as to not

place your fingers in the space between the stud

and main unit, such as the guard section (see

Fig.

4

), battery, etc.

䡬

After cutting, the cut section of the stud is very

sharp and therefore dangerous. Be very careful

when handling the stud.

Fig. 4

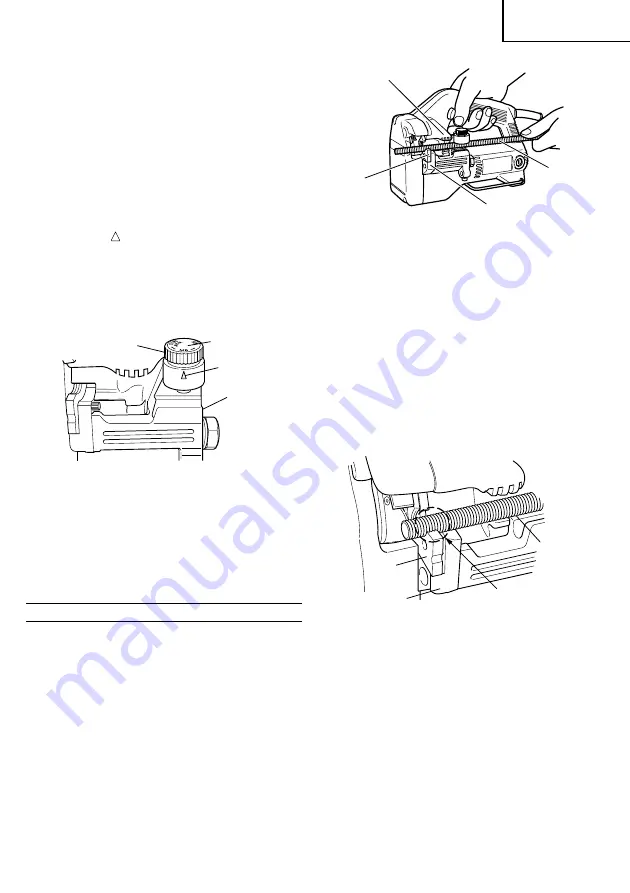

1. Normal cutting method

(1) Lightly pull the trigger switch and move bracket (A),

stopping with the cutter in the open position shown

in

Fig. 4

.

(The switch is a variable speed switch. Lightly pulling

the trigger switch will cause bracket (A) to move

slowly.)

(2) As shown in

Fig. 5

, set the stud to be cut in the

cutter on the bracket (B) side, making sure that the

threads correctly mesh with each other.

(3) While maintaining the stud in a horizontal position,

pull the trigger switch all the way to cut the stud

(

Fig. 4

).

(4) After cutting turn off the switch with bracket (A)

facing directly upward. The unit stops with the

cutter in the open position, thus making it easier

to proceed to the next operation.

Fig. 5

2. Cutting fixed lengths

When cutting several studs to the same length,

using the equipment in the following way will making

cutting operations more efficient.

(1) First cut one stud to the required length, and then

use it as a fixed length guide.

(2) Insert the stud used as a fixed length guide in the

stud attachment hole found on the main unit stud

guide and use the hexagonal bar wrench to tighten

and secure the hex. socket hd. bolt. Adjust at this

time so that the distance between the end of the

stud used as a fixed length and the cutter is the

necessary length.

(3) Insert the stud for cutting in the cutter, aligning the

end with that of the stud used as a cutting guide,

and then cut the stud.

Screw size

display

Dial

Mark

Stud guide

Guard section

Cutter

Stud

Bracket (B)

Cutter

Bracket (B)

Stud

Correctly mesh

Summary of Contents for CL 10SA

Page 43: ...English 42 ...