English

38

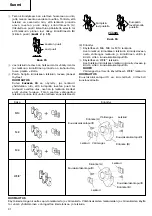

Fig. 10

CAUTION

This trimmer is specially designed for Studs Cutter.

The flange on studs cut with a hacksaw or disc

grinder is too large for this trimmer so that the

trimmer does not rotate and it is not possible to

remove flange.

CUTTER LIFE AND REPLACEMENT

1. Cutter life

As is shown in

Fig. 11

, repeated cutting can cause

breaking and warping of the cutter edge. Using the

cutter in this condition can produce flange on the

cutting location of the studs so that the threads are

distorted. This will prevent clean cuts and make it

impossible to insert the nut.

Fig. 11

As is shown in

Fig. 12

, the edge is found on four

locations on the cutter. Use the method described

below to change the attachment direction of the

cutter to allow a total of four usages.

If the nut does not fit on the screw due to breaking

and warping of the edge, change the cutter

attachment direction to use the edge without

breaking and warping or replace with a new cutter.

Fig. 12

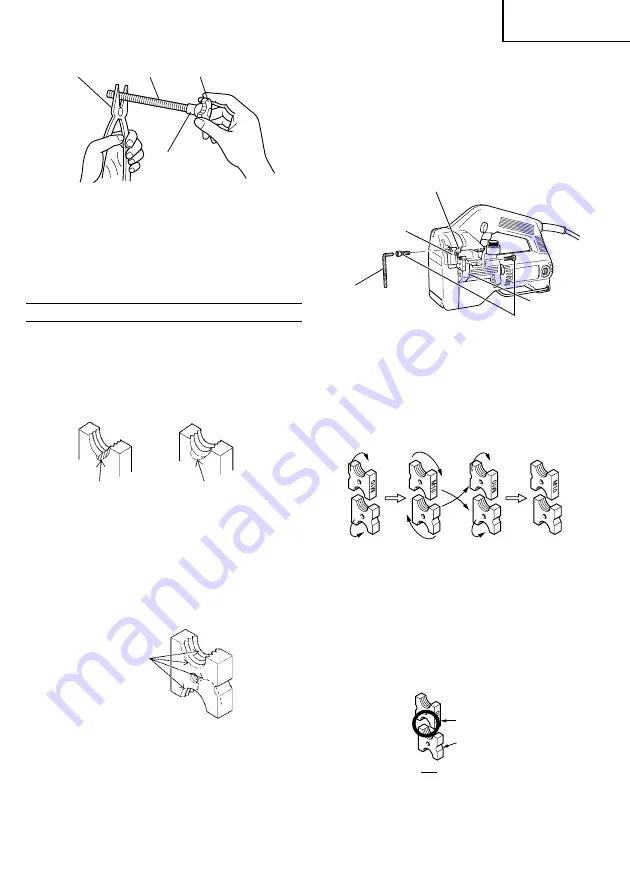

2. Changing the cutter attachment direction or replacing

the cutter

(1) Before removing:

1

Pull the trigger switch lightly to slowly operate

bracket (A) and set the cutter in an open condition.

2

Next, make absolutely certain that you turn off the

switch and unplug the power cord from the outlet.

(2) Removal

WARNING!

To prevent accidents, always be sure to turn the

switch OFF and unplug the power cord from the

receptacle.

Use the accessory hexagonal bar wrench to remove

the hex. socket hd. bolt. It is now possible to remove

the cutter and spacer.

Fig. 13

(3) Before attaching

1

There are four edges on the cutter. As shown in

Fig. 14

, by changing the position of the edge it is

possible to use the blade four times.

Fig. 14

2

There is directionality for cutter attachment in order

to change the position of the edge. Check that the

cutter has been attached so that the side without

the notch on the cutter can be seen on bracket (A)

(movable side) when seen from the main unit viewed

from the front or that the notch on the cutter

surface on bracket (B) (fixed side) can be seen (

Figs.

2

and

15

).

Fig. 15

3

If there is breakage or warping on the cutter edge

or if there are bulges on the cutter attachment

surface, use a file to the areas flat.

Breaking

Warping

Four edges

on the cutter

1st time

2nd time

3rd time

4th time

Stud

Entrance

Grip

Pliers

Bracket (A)

Hex. bar

wrench

Bracket (B)

Hex. socket hd. bolt

Cutter

Notch side

Side without notch

DO

Turning to

the back side

(

)

Turning to

the back side

(

)

Re-

insertion

(

)

Turning to

the back side

(

)

Summary of Contents for CL 10SA

Page 43: ...English 42 ...