-11-

• Carburetor ass’y

3. Disassembly and reassembly of the carburetor ass'y

[Tools required]

• Hex. bar wrench (4 mm)

• Pliers

(1) Disassembly

• Clamp both ends of the Insulator Clip

[147]

with pliers. The Insulator Clip

[147]

opens wider. Remove

the Insulator Clip

[147]

from the groove of the Carburetor Insulator

[149]

and move it toward the

Insulator Plate

[148]

.

• Pull out the Carburetor Insulator

[149]

from the Cylinder

[146]

. Be careful not to break the insulator.

• Remove the Choke Button

[191]

and Choke Rod Rubber

[192]

from Carburetor Ass'y (C3M)

[151]

.

• Lift up the Carburetor Bracket

[181]

and remove the Throttle Rod

[135]

from Carburetor Ass'y (C3M)

[151]

and the Throttle Lever

[134]

.

• Remove the Fuel Pipes

[105] [137]

from Carburetor Ass'y (C3M)

[151]

.

• Remove Fuel Pipe (FKM)

[150]

from the elbow joint.

• Loosen the two Bolts M5 x 55

[195]

by using a hex. bar wrench (4 mm), and then remove the

Carburetor Insulator

[149]

, Insulator Plate

[148]

, two Square Nuts (B) M5

[167]

, Carburetor Ass'y

(C3M)

[151]

, Carburetor Packing

[180]

, and Carburetor Bracket

[181]

.

• Remove the Fuel Pipe

[166]

from Carburetor Ass'y (C3M)

[151]

and the Carburetor Bracket

[181]

.

• Remove Fuel Pipe (FKM)

[150]

from Carburetor Ass'y (C3M)

[151]

.

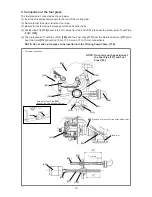

(2) Reassembly

Reassembly can be conducted by reversing the disassembly procedure. However, special attention

should be given to the following items.

• Subassemble the parts of the Carburetor Insulator

[149]

as shown in the figure below before mounting

the Carburetor Insulator

[149]

on the Cylinder

[146]

. Make sure the throttle valve and choke valve of

Carburetor Ass'y (C3M)

[151]

move smoothly after subassembly.

• Fit the lip portion of the Carburetor Insulator

[149]

along the groove of the Insulator Plate

[148]

when

mounting the Carburetor Insulator

[149]

on the Insulator Plate

[148]

.

• Be careful not to bend the Fuel Pipes

[105] [137] [150] [166]

. For details, see “4. Connection of the

fuel pipes.”

• For reassembly of the Throttle Rod

[135]

, first insert its tip into the throttle valve of Carburetor Ass'y

(C3M)

[151]

, and then fit the rod to the Throttle Lever

[134]

while pulling the Throttle Lever

[134]

.

• Apply 0.1 to 0.2 g of Alvania Grease RL3 to the sliding portions of the Choke Button

[191]

and Choke

Rod Rubber

[192]

(in the range of 16 to 20 mm from the end of the Choke Button

[191]

).

• Orient the Choke Button

[191]

and Choke Rod Rubber

[192]

correctly. Insert Cleaner Box (A)

[189]

into

the slit portion of the Choke Rod Rubber

[192]

when reassembling Cleaner Box (A)

[189]

.

[195]

[149]

[147]

[148]

[151]

[180]

[181]

[146]

Ends

[167]

Subassemble and mount to the cylinder.

[166]

[150]