7

English

(2) Install the dust collector hose for the power tool

in the accessory hose. (

Fig. 1

)

CAUTION

䡬

Do not use the dust collection hose when cutting

metal.

䡬

Always install a rubber cap on the dust collection

adapter when the dust collection hose is not used.

INSTALLING/REMOVING DIAMOND WHEEL

1. Installation

(1) Wipe the cutting dust from the spindle and washers.

(2) Make sure the rotation direction of the diamond

wheel conforms to the direction indicated on the

wheel guard and install the diamond wheel as shown

in

Fig. 2

and

3

.

• Install the wheel washer (B) (silver) on the inner

side when the hole diameter of the diamond wheel

is 22.2 mm.

• Install the wheel washer (C) (black) on the inner

side when the hole diameter of the diamond wheel

is 20.0 mm.

(3) Press the lock pin and secure the spindle. Tighten

the bolt adequately with the provided wrench.

(

Fig. 5

and

6

)

NOTE

䡬

Always use the provided wrench to secure the bolt.

䡬

Be careful because the bolt tightens to the left

(counterclockwise direction) to prevent it from being

loosened during cutting. (

Fig. 6

)

2. Removal

Remove the bolt with the provided wrench and

remove the diamond wheel. (

Fig. 6

)

CUTTING

1. Wheel guard adjustment (Fig. 4)

Adjust the wheel guard angle with the knob so dust

and debris from the material or sparks do not contact

the operator during the cutting operation.

2. Cutting procedures (Fig. 7)

(1) Place this tool on the material to be cut and align

the premarked line and the diamond wheel.

The cutting can be performed smoothly if you cut

straight ahead on the scribed line in the initial cut.

OPTIONAL ACCESSORIES (sold separately)

(1) Diamond wheels for dry cutting (segment type)

(2) Cutting wheels

(3) Wheel washer (A) (hole diameter 25.4mm)

Optional accessories are subject to change without notice.

APPLICATION

䡬

Cutting or scribing concrete

䡬

Cutting or scribing tile

䡬

Cutting or scribing stone

䡬

Cutting or scribing roof tile

䡬

Cutting steel

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specified on the product

nameplate.

2. Power switch

Ensure that the power switch is in the OFF position.

If the plug is connected to a power receptacle while

the power switch is in the ON position, the power

tool will start operating immediately, which could

cause a serious accident.

3. Extension cord

When the work area is removed from the power

source, use an extension cord of sufficient thickness

and rated capacity. The extension cord should be

kept as short as practicable.

4. Checking and installing the diamond wheel

Check the diamond wheel is a specified one and

is not cracked, broken or bent. Check the diamond

wheel is installed securely. For installation, refer to

“Installing/removing diamond wheel”.

5. Check that the knob used to secure the wheel guard

is tight.

Make sure that the knob that secures the wheel

guard is adequately tight.

If this knob is loose, it may result in injury to the

operator. (

Fig. 4

)

INSTALLING DUST COLLECTION HOSE

When cutting a material which generates cutting dust,

use the dust collection hose as follows:

(1) Remove the rubber cap and install the accessory

hose. (

Fig. 1

)

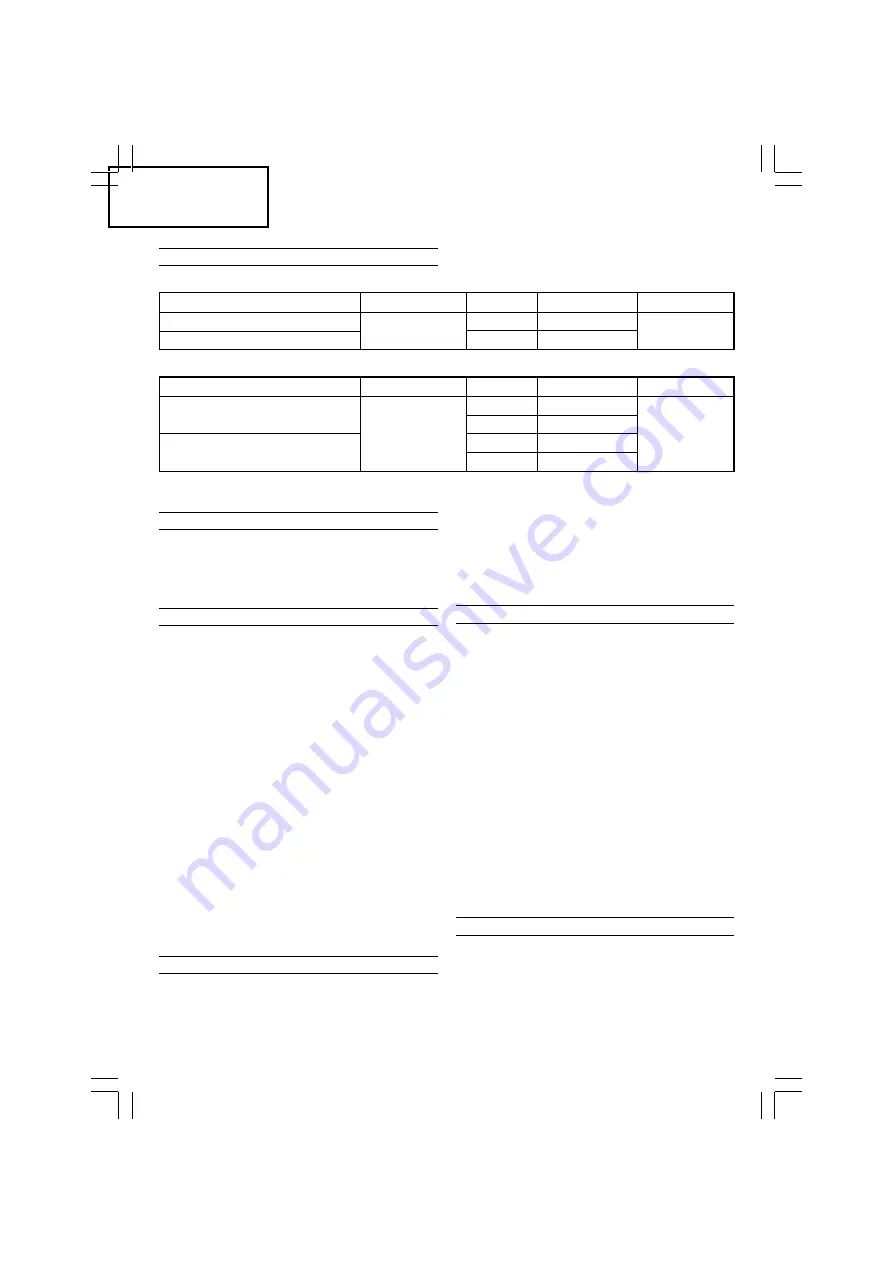

Type

Wheel dia. (mm)

Code No.

Thickness (mm)

Hole dia. (mm)

For concrete and masonry

305

985618

2.8

22.2

For abrasive materials

985619

3.0

Type

Wheel dia. (mm)

Code No.

Hole dia. (mm)

per pkg.

Metal cutting wheel

985609

22.2

305

985608

25.4

10 pcs.

Masonry cutting wheel

985611

22.2

985610

25.4

01Eng_CM12Y_WE

7/29/13, 3:10 PM

7