MODELS CR 12V/CR 12

−

1

−

1. NOTES ON DISASSEMBLY AND REASSEMBLY:

The circled numbers in the descriptions below correspond to the item numbers in the Parts Lists and ex-

ploded assembly diagrams.

1-1. Diassembly:

(1) Disassembly of the Upper Cover Ass’y

11

:

After removing the Base

1

and the Saw Blade

501

, take off the Insulation Cover

2

by pulling it

forward (toward the blade mounting end). Then, shift the Plunger

5

forward (toward the blade

mounting end) and loosen the four M5 x 16 Machine Screws

10

which secure the Upper Cover Ass’y

11

. The Upper Cover A’ssy can then be removed by lifting it upwards.

(2) Disassembly of the Plunger

5

from the Upper Cover Ass’y

11

:

First remove the two M5 x 12 Hexagon Socket Flat Hd. Screws

15

which secure the Connector

14

.

As these are seal lock screws which are secured by an adhesive agent, it may be necessary to heat the

Upper Cover Ass’y

11

to a temperature of 100°C - 150°C to permit their removal. The Plunger

5

can then be removed from the Upper Cover Ass’y

11

by pulling it out toward the front (toward

the blade mounting end) .

(3) Disassembly of the Gear Cover

26

from the Housing Ass’y

42

:

Remove the Brush Caps

39

, and take out the Carbon Brushes

40

. Next, remove the four D5 x 35

Tapping Screws

45

. The Gear Cover

26

(together with the Armature

30

and ralated parts) can then

be removed from the Housing Ass’y

42

.

(4) Disassembly of the Armature

30

from the Gear Cover

26

:

Remove the three M4 x 12 Machine Screws

44

. The Armature

30

(together with the Bearing Cover

29

) can the be removed from the Gear Cover

26

.

(5) Disassembly of the Bearing Cover

29

from the Armature

30

:

First, remove the C-Type Retaining Ring

27

from the Armature

30

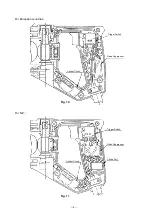

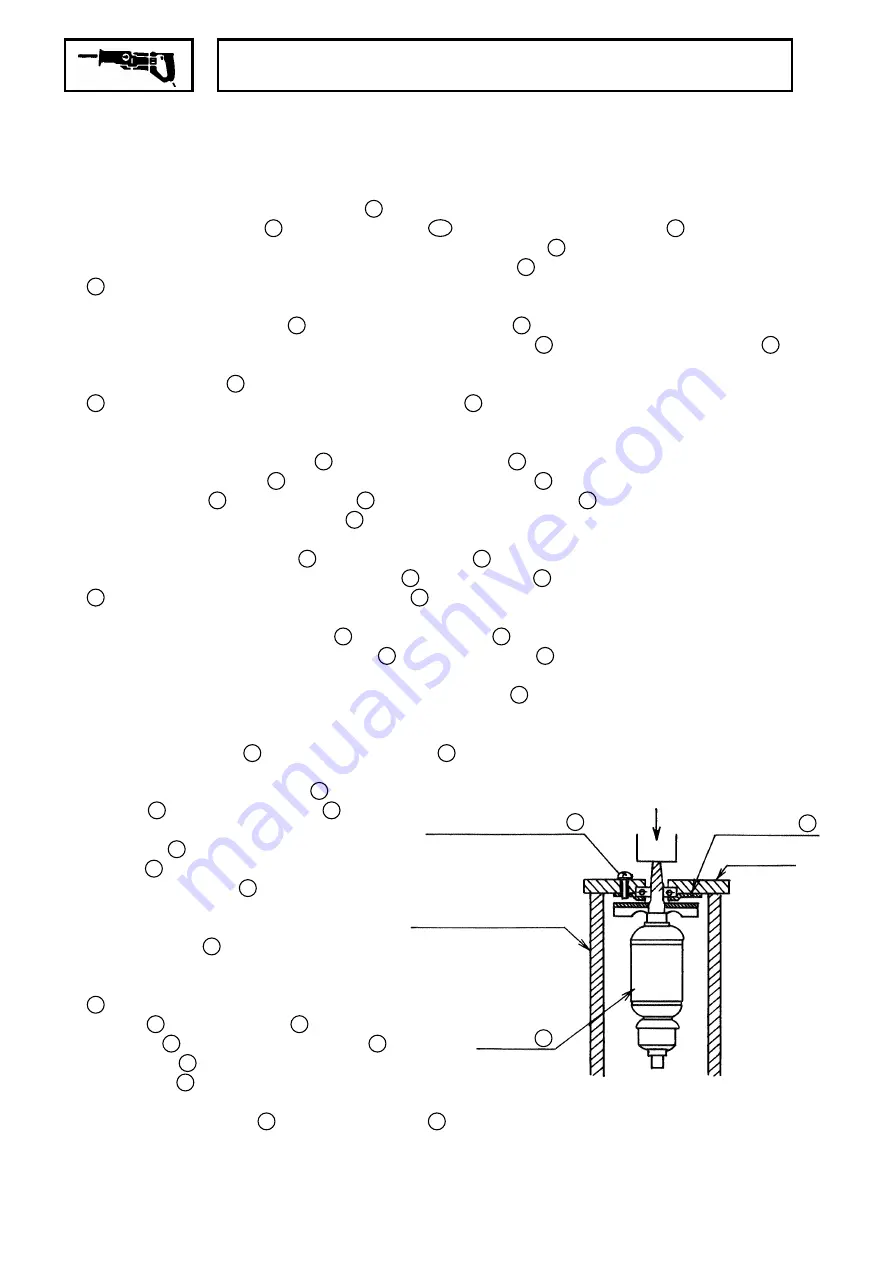

. Then, as illustrated in Fig.5,

mount the Armature on a J-173 Puller Attachment (special repair tool, Code No. 970954) , and

secure it in position with the three M4 x 12 Machine Screws

44

. Next, support the J-173 Puller

Attachment with an appropriate tubular jig (inner diameter of 80 mm or more, outer diameter of

130 mm of less) , and push down on the Pinion end of the Armature with a hand press to loosen and

remove the Armature

30

from the Bearing Cover

29

.

(6) Disassembly of the Gear Ass’y

21

and

Spindle

25

from the Gear Cover

26

:

Remove the M6 x 16 Hexagon Socket Flat

Hd. Screw

18

which secures the Balance

Weight

19

, and remove the Balance Weight

from the Gear Cover

26

. As this screw

is a seal lock screw which is secured by an

adhesive agent, it may be necessary to heat

the Gear Cover

26

to a temperature of

100°C - 150°C to permit its removal. Then,

through the hole provided in the Gear Ass’y

21

, remove the three M4 x 12 Flat Hd.

Screws

22

. The Gear Ass’y

21

, Bearing

Cover (A)

23

, 6202VVCM Ball Bearing

24

and Spindle

25

can be taken out of the

Gear Cover

26

in a single body. Finally,

push down on the gear-side end of the Spindle

to separate the Spindle

25

from the Gear Ass’y

21

. .

J-173 Puller

Attachment

Tubular Jig

Inner Dia: 80mm or more

Outer Dia: 130mm or less

M4 x 12 Machine Screws

44

(3 pcs)

Armature

30

Bearing Cover

29

Push

Fig. 5

Summary of Contents for CR12

Page 1: ......