PRODUCT NAME

Hitachi Engine Pole Saw

Models

CS 27EPAP(S)

CS 27EPA(S)

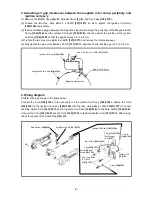

TROUBLESHOOTING GUIDE ---------------------------------------------------------------------------------------------- 1

1. Troubleshooting and correction ------------------------------------------------------------------------------- 1

REPAIR GUIDE ----------------------------------------------------------------------------------------------------------------- 3

1. Precaution on maintenance, inspection and repair ------------------------------------------------------ 3

2. Inspection criteria for each section and consumable parts -------------------------------------------- 3

CONTENTS

Page

LIST Nos.

CS 27EPAP: F021

CS 27EPA: F020

Sep. 2012

International Sales Division

䠟