12

English

Guide

bar

(Fig.

35)

Before using the machine, clean the groove and oiler port (39) in the

bar with the special gauge o

ff

ered as an optional accessory.

Side

case

(Fig.

36)

Always keep the side case and drive area clean of saw dust and

debris. Periodically apply oil or grease to this area to protect from

corrosion as some trees contain high levels of acid.

Fuel

fi

lter

(Fig.

37)

Remove the fuel

fi

lter from the fuel tank and thoroughly wash it in

solvent. After that, push the

fi

lter into the tank completely.

NOTE

If

the

fi

lter is hard due to dust and dirt, replace it.

Chain

oil

fi

lter

(Fig.

38)

Remove the oil

fi

lter and thoroughly wash it in solvent.

Cleaning

the

cylinder

fi

ns

(Fig.

39)

When wood chips are caught between cylinder

fi

ns (40), the engine

may overheat, resulting in lower output. To avoid this, always keep

cylinder

fi

ns and fan case clean.

Every 100 operating hours, or once a year (more often if conditions

require), clean

fi

ns and external surfaces of engine of dust, dirt and

oil deposits which can contribute to improper cooling.

For long-term storage

Drain all fuel from the fuel tank. Start and let engine run until it stops.

Repair any damage which has resulted from use. Clean the unit with

a clean rag, or the use of high pressure air hose. Put a few drops of

two-cycle engine oil into the cylinder through the spark plug hole,

and spin the engine over several times to distribute oil.

Cover the unit and store it in a dry area.

CHAIN

SHARPENING

Parts

of

a

cutter

(Fig.

40,

41)

WARNING

○

Gloves should be used when sharpening chain.

○

Be sure to round o

ff

the front edge to reduce the chance of

kickback or tie-strap breakage.

41. Top plate

42. Working corner

43. Side plate

44. Gullet

45. Heel

46. Chassis

47. Rivet hole

48. Toe

49. Depth gauge

50. Correct angle on top plate (degree of angle depends on chain

type)

51. Slightly protruding “hook” or point (curve on non-chisel chain)

52. Top of depth gauge at correct height below top plate

53. Front of depth gauge rounded o

ff

LOWERING

DEPTH

GAUGES

WITH

A

FILE

1) If you sharpen your cutters with a

fi

le holder, check and lower the

depth.

2) Check depth gauges every third sharpening.

3) Place depth gauge tool on cutter. If depth gauge projects,

fi

le

it level with the top of the tool. Always

fi

le from the inside of the

chain toward an outside cutter. (

Fig.

42

)

4) Round

o

ff

front corner to maintain original shape of depth gauge

after using depth gauge tool. Always follow the recommended

depth gauge setting found in the maintenance or operator

manual for your saw. (

Fig.

43

)

GENERAL

INSTRUCTIONS

FOR

FILING

CUTTERS

File (54) cutter on one side of the chain from the inside out. File on

forward stroke only. (

Fig.

44

)

5) Keep all cutters the same length. (

Fig.

45

)

6) File enough to remove any damage to cutting edges (side plate

(55) and top plate (56)) of cutter. (

Fig.

46

)

SHARPENING

ANGLES

FOR

SHARPENING

SAW

CHAIN

1. Part Number

95VP

2. Pitch

0.325”

3. Depth Gauge Setting

0.025"

4. Side Plate Filing Angle

85°

5. Top Plate Angle

30°

6. File Guide Angle

10°

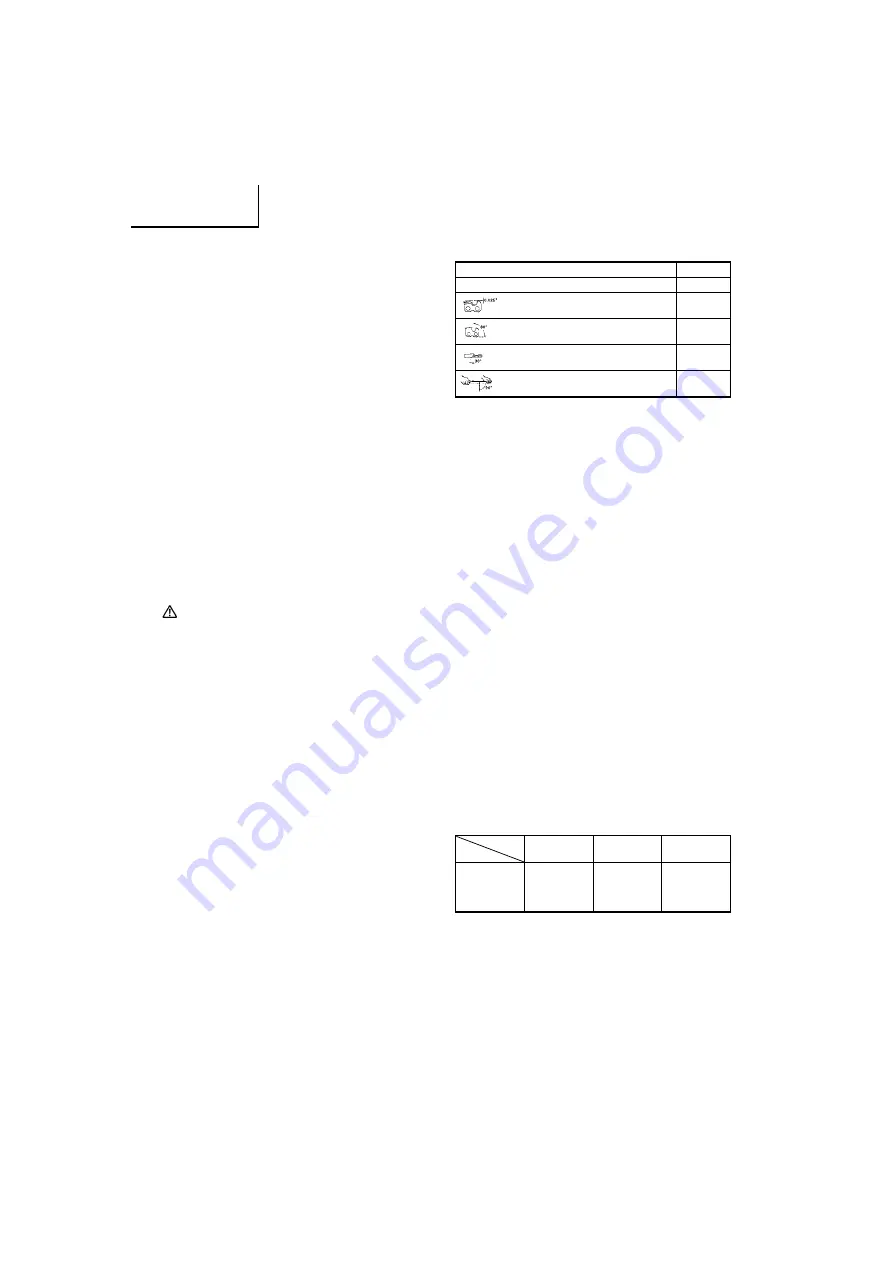

Maintenance

schedule

Below you will

fi

nd some general maintenance instructions. For

further information please contact HITACHI dealer.

Daily

maintenance

○

Clean the exterior of the unit.

○

Clean the chain oil

fi

lter port.

○

Clean the groove and oil

fi

lter port in the guide bar.

○

Clean the side case of saw dust.

○

Check that the saw chain is sharp.

○

Check that the bar nuts are su

ffi

ciently tightened.

○

Make sure that the chain transport guard is undamaged and that

it can be securely

fi

tted.

○

Check that nuts and screws are su

ffi

ciently tightened.

Especially inspect the bolt of mu

ffl

er and ensure that they are

properly tightened before starting engine. Should any of the

bolts be loose, retighten them immediately. Failure to do so

could result in serious hazard.

○

Check the tip of the bar. Please exchange it for the new one

when it is worn out.

○

Check the band of chain brake. Please exchange it for the new

one when it is worn out.

Weekly

maintenance

○

Check the starter, especially cord and return spring.

○

Clean the exterior of the spark plug.

○

Remove the spark plug and check the electrode gap. Adjust it to

0.6 mm or change the spark plug.

○

Clean the cooling

fi

ns on the cylinder and check that the air

intake at the starter is not clogged.

○

Clean the air

fi

lter.

Monthly

maintenance

○

Rinse the fuel tank with gasoline, and clean fuel

fi

lter.

○

Clean chain oil

fi

lter.

○

Clean the exterior of the carburetor and the space around it.

○

Clean the fan and the space around it.

NOTE

When ordering the parts to your nearest dealer, please use the

item numbers showing on the parts breakdown section in this

instruction.

BAR NO.

LENGTH-

TYPE

CHAIN NO.

MODEL NO.

OREGON

107498

105191

104968

105355

13”

15”

16”

18”

95VP-56

95VP-64

95VP-66

95VP-72

000Book̲CS40EA̲EE.indb 12

000Book̲CS40EA̲EE.indb 12

2010/09/03 14:50:32

2010/09/03 14:50:32