-10-

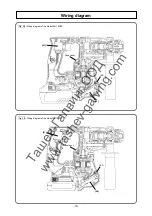

Fig. 15

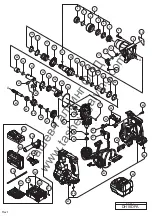

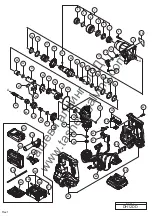

(4) Put the LED, main PCB ass’y, and stator FET PCB ass'y in housing (A) in this order.

(5) Mount the battery terminal to housing (A). Put the red and black internal wires between the stator FET

PCB ass’y and battery terminal in housing (A). Then, put the cable sleeve sheathed internal wire between

the main PCB ass’y and battery terminal in housing (A).

Fig. 14

Stator FET PCB ass’y

LED

Main PCB ass’y

Stator FET PCB ass’y

Battery terminal

Red and black internal wires

Main PCB ass’y

Cable sleeve

Stator FET PCB ass’y

Cable sleeve

Model DH 18DPA

Model DH 12DD

Battery terminal

Red and black internal wires

Main PCB ass’y

Та

ше

в

-

Га

лв

ин

г

ОО

Д

www.tashev-galving.com