23

Reassembly

Reassembly can be accomplished by following the disassembly procedure in reverse. However, special

attention should be given to the following items.

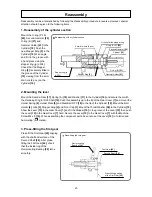

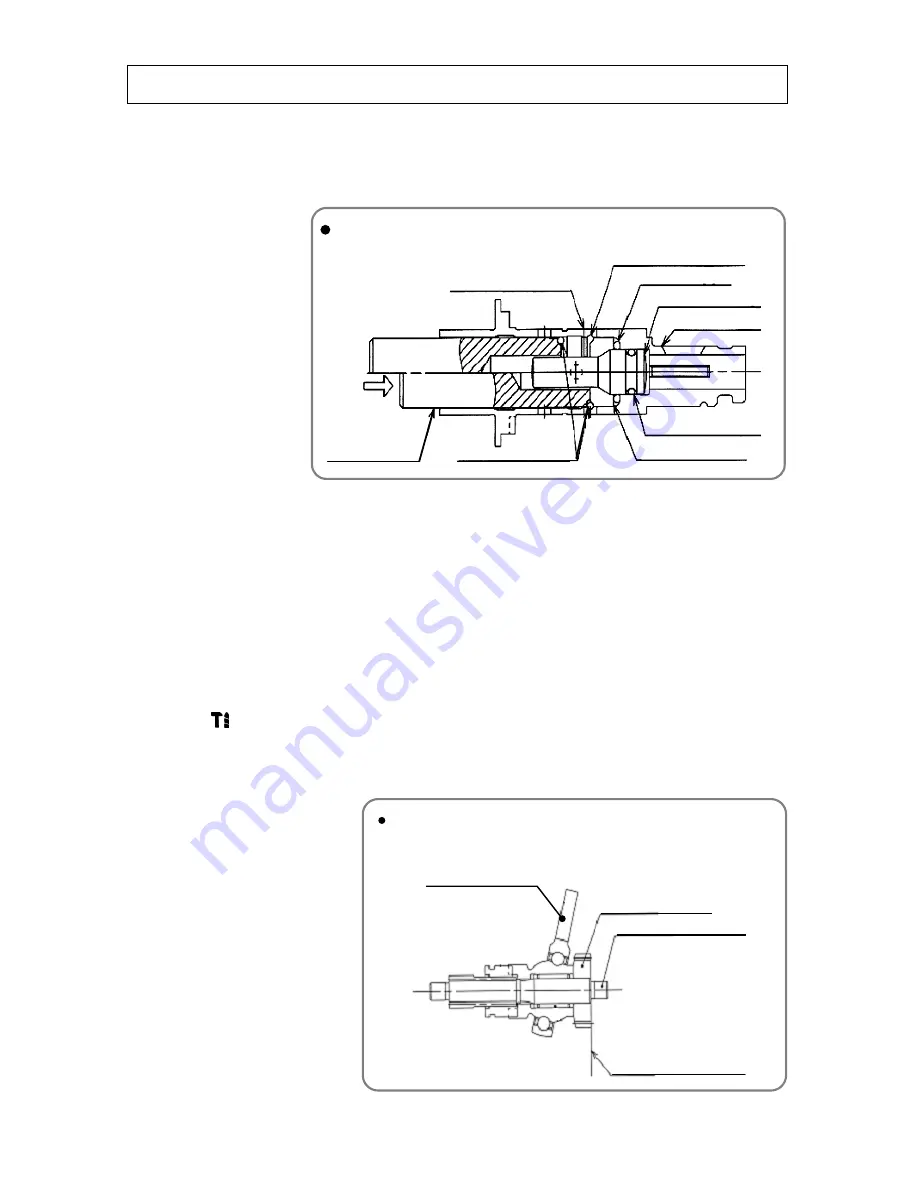

1. Reassembly of the cylinder section

Mount the O-ring (P-15)

[22]

, Second Hammer

[20]

,

O-ring (B)

[21]

and

Hammer Holder

[23]

in the

Cylinder

[19]

. Push the

new Stopper Ring

[2]

in the

Cylinder

[19]

at an angle

and fit it in the groove with

a hand press using the

stopper ring jig [J-234].

Check that the Stopper

Ring

[2]

is securely fitted in

the groove of the Cylinder

[19]

viewing from the 4 mm

dia. hole (2 pcs.) on the

Cylinder

[19]

.

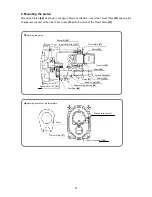

2. Mounting the lever

Mount the Second Gear

[17]

, Spring (A)

[16]

and Washer

[11]

to the Cylinder

[19]

and secure them with

the Retaining Ring for D25 Shaft

[10]

. Push this assembly up to the tip of the Gear Cover

[7]

and mount the

Holder Spring

[6]

, Holder Plate

[5]

and Steel Ball D7.0

[18]

to the tip of the Cylinder

[19]

. Mount the Ball

Holder

[4]

, Grip

[3]

, Stopper Ring

[2]

and Front Cap

[1]

. Mount the Thrust Washer

[26]

to the Cylinder

[19]

.

Show the Lever

[12]

in the Gear Cover

[7]

and fit the Stopper

[14]

in the groove of the Lever

[12]

then push

the Lever

[12]

in the Gear Cover

[7]

hard. Secure the Lever

[12]

to the Gear Cover

[7]

with the Machine

Screw M4 x 5

[15]

. When assembling the component parts, be sure to set the Lever

[12]

to “rotation and

hammering” (

marks).

3. Press-fitting the first gear

Press-fit the First Gear

[40]

aligning

with the shaft end surface of the

Second Shaft

[36]

. After press-

fitting the First Gear

[40]

, check

that the inside ring of the

Reciprocating Bearing

[38]

turns

smoothly.

Reassembly of the cylinder section

4 mm dia. hole (2 pcs.)

Groove for the stopper ring

O-ring (P-15)

[22]

Second Hammer

[20]

Cylinder

[19]

Stopper Ring

[2]

Stopper ring jig

[J-234]

Hammer Holder

[23]

O-ring (B)

[21]

Press-fitting the first gear

First Gear

[40]

Second Shaft

[36]

Reciprocating

Bearing

[38]

Press-fitting position

of the First Gear

[40]