2

Equipped with the new lithium-ion battery

Each of the Types BCL 1430 and EBM 1830 lithium-ion batteries is equipped with the overdischarge

protection circuit, overload protection circuit, and voltage monitoring circuit for each cell to prevent

reduction of the battery life due to overdischarge (overuse) or overcharge (excessive charging) of the

battery. The number of charging/discharging is about 1,500. Precautions for use of the Types BCL 1430

and EBM 1830 lithium-ion batteries.

Each of the Types BCL 1430 and EBM 1830 lithium-ion batteries is equipped with a protective function that

automatically stops output to extend the battery life. The motor may stop automatically in either of the

following case or even if the switch is depressed continuously during operation. This is because the

protective function is activated. The battery is not faulty.

The motor may stop automatically when the remaining battery level is low (when the battery voltage is

decreased to about 8V (Type BCL 1430)/when decreased to about 12 V (Type EBM 1830)). Charge the

battery immediately in such case.

The motor may stop if the Models DH 14Dland DH 18DL are overloaded. In such case, release the switch

and eliminate the cause of the overload problem. Then the Models DH 14DL and DH 18DL are operable.

Replaceable carbon brush for longer motor life

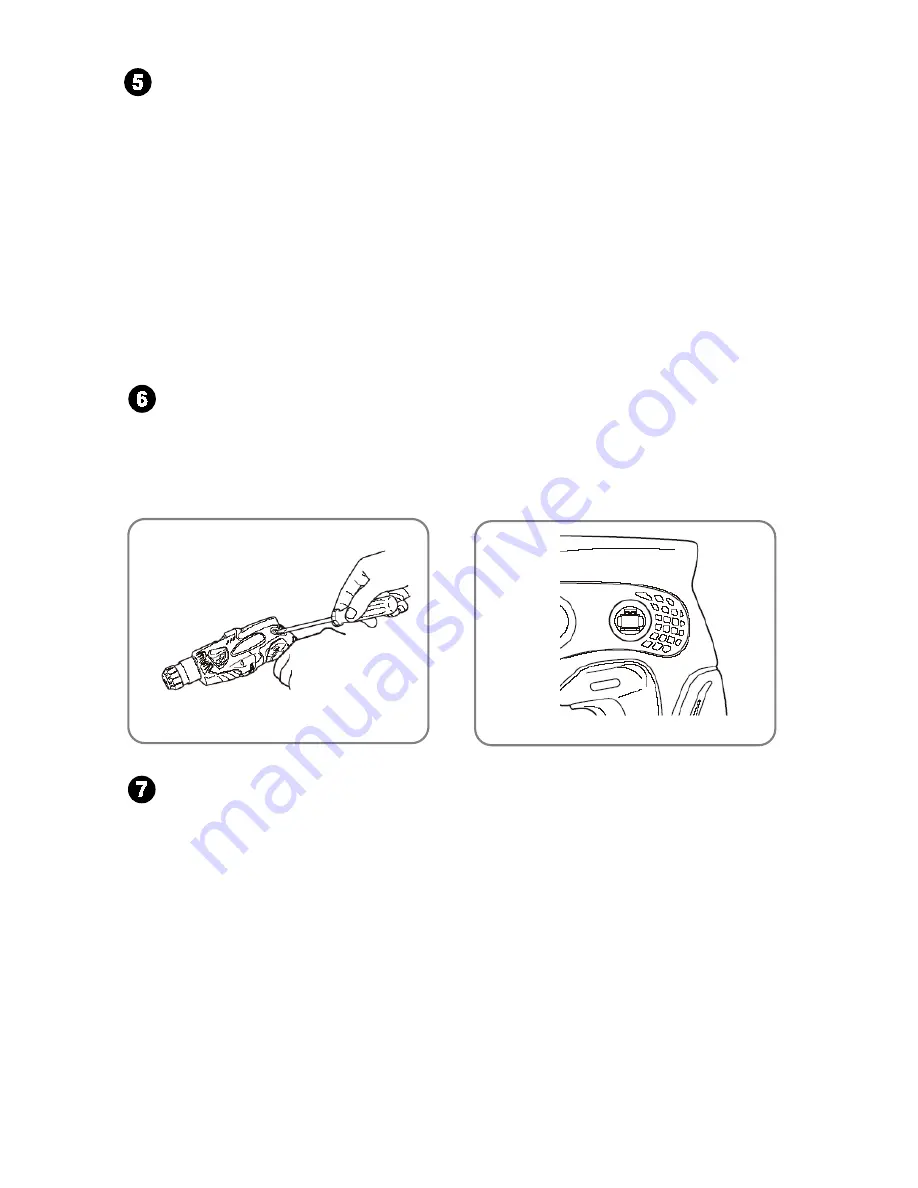

The carbon brushes are replaceable from the outside. Take out the carbon brush by first removing the

brush cap and then hooking the protrusion of the carbon brush with a slotted head screw driver, etc. When

installing the carbon brush, choose the direction so that the nail of the carbon brush agrees with the contact

portion outside the brush tube. Then push it in with a finger Lastly, install the brush cap.

Idle striking prevention mechanism

The idle striking prevention mechanism in the Models DH 14DL, DH 14DMR, DH 18DL and DH 18DMR are

different from those of conventional hammer drills in other classes. When the drill bit is lifted from the

concrete surface on completion of drilling or during no-load operation, the reciprocating bearing that

converts rotation into reciprocating motion stops to prevent idle striking.

Upon lifting the drill bit from the concrete surface, the tool shaft (cylinder) is moved forward about 5 mm by

the force of spring (B). Then the clutch is moved forward by the thrust plate that is connected to the cylinder

to disengage the clutch from the reciprocating bearing. Thanks to the needle bearing on the second shaft,

the reciprocating bearing can idle. Accordingly, rotation of the second shaft is not transmitted to the

reciprocating bearing and the reciprocating bearing stops to stop the striking motion of the piston and the

striker. The pressing force of spring (B) is as low as 1.0 kg to 2.0 kg in comparison with the conventional

mouth system. The Models DH 14DL, DH 14DMR, DH 18DL and DH 18DMR are also suitable for drilling in

upward direction.