--- 6 ---

B. Anchor setting (hammering only)

Anchor setting adapter (SDS-plus shank)

Part name

W-1/4 Anchor setting adapter-A

W-5/16 Anchor setting adapter-A

W-3/8 Anchor setting adapter-A

W-3/8 Anchor setting adapter-A

Code No.

302976

302975

303621

302974

Anchor setting bar to permit anchor setting operation with the rotary hammer

Overall length

260

260

160

260

Part name

W-1/4 Anchor setting adapter-B

W-5/16 Anchor setting adapter-B

W-3/8 Anchor setting adapter-B

W-3/8 Anchor setting adapter-B

Code No.

302979

302978

303622

302977

Overall length

260

260

160

260

Internal cone type

External cone type

Anchor setting bar for manual anchor setting

Anchor setting adapter

Part name

W-1/4 Anchor setting adapter-A

W-5/16 Anchor setting adapter-A

W-3/8 Anchor setting adapter-A

W-1/2 Anchor setting adapter-A

W-5/8 Anchor setting adapter-A

Code No.

971794

971795

971796

971797

971798

Part name

W-1/4 Anchor setting adapter-B

W-5/16 Anchor setting adapter-B

W-3/8 Anchor setting adapter-B

W-1/2 Anchor setting adapter-B

W-5/8 Anchor setting adapter-B

Internal cone type

External cone type

Code No.

971799

971800

971801

971802

971803

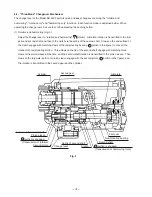

C. Large hole boring (ro hammering)

(Guide plate)

Center pin, core bit, core bit shank and guide plate

Core bit shank

(SDS-plus shank)

Core bit

Center pin

(1) Center pin (Do not use bit with outer diameter of 25 mm (31/32") and 29 mm (1-5/32").)

Center pin (A)

Core bit (outer diameter) 32, 35, 38 mm (1-1/4", 1-3/8", 1-1/2") Code No. 982684

Center pin (B)

Core bit (outer diameter) 45, 50 mm (1-25/32", 2")

Code No. 982685

Anchor setting bar

(2) Guide plate

Core bit (outer diameter ) (mm)

32 (1-1/4")

35 (1-3/8")

38 (1-1/2")

45 (1-25/32")

Code No.

982686

982687

982688

982689

Core bit (outer diameter ) (mm)

50 (2")

Code No.

982690