Reviews:

No comments

Related manuals for DH 24DVA

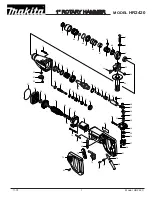

BHR202

Brand: Makita Pages: 3

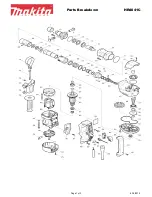

HR2432

Brand: Makita Pages: 4

HR3000C

Brand: Makita Pages: 4

HR2010

Brand: Makita Pages: 6

HR2420

Brand: Makita Pages: 5

HR4041C

Brand: Makita Pages: 3

HR4040C

Brand: Makita Pages: 14

HR4030C

Brand: Makita Pages: 13

HR2450F

Brand: Makita Pages: 18

HR2300

Brand: Makita Pages: 23

HR4510C

Brand: Makita Pages: 4

HR4013C

Brand: Makita Pages: 19

HR2010

Brand: Makita Pages: 3

HR2450 Series

Brand: Makita Pages: 5

HR2000

Brand: Makita Pages: 6

HR2010

Brand: Makita Pages: 16

HR1830F

Brand: Makita Pages: 28

HR2230

Brand: Makita Pages: 40