--- 18 ---

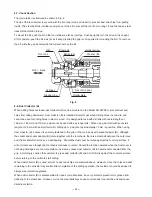

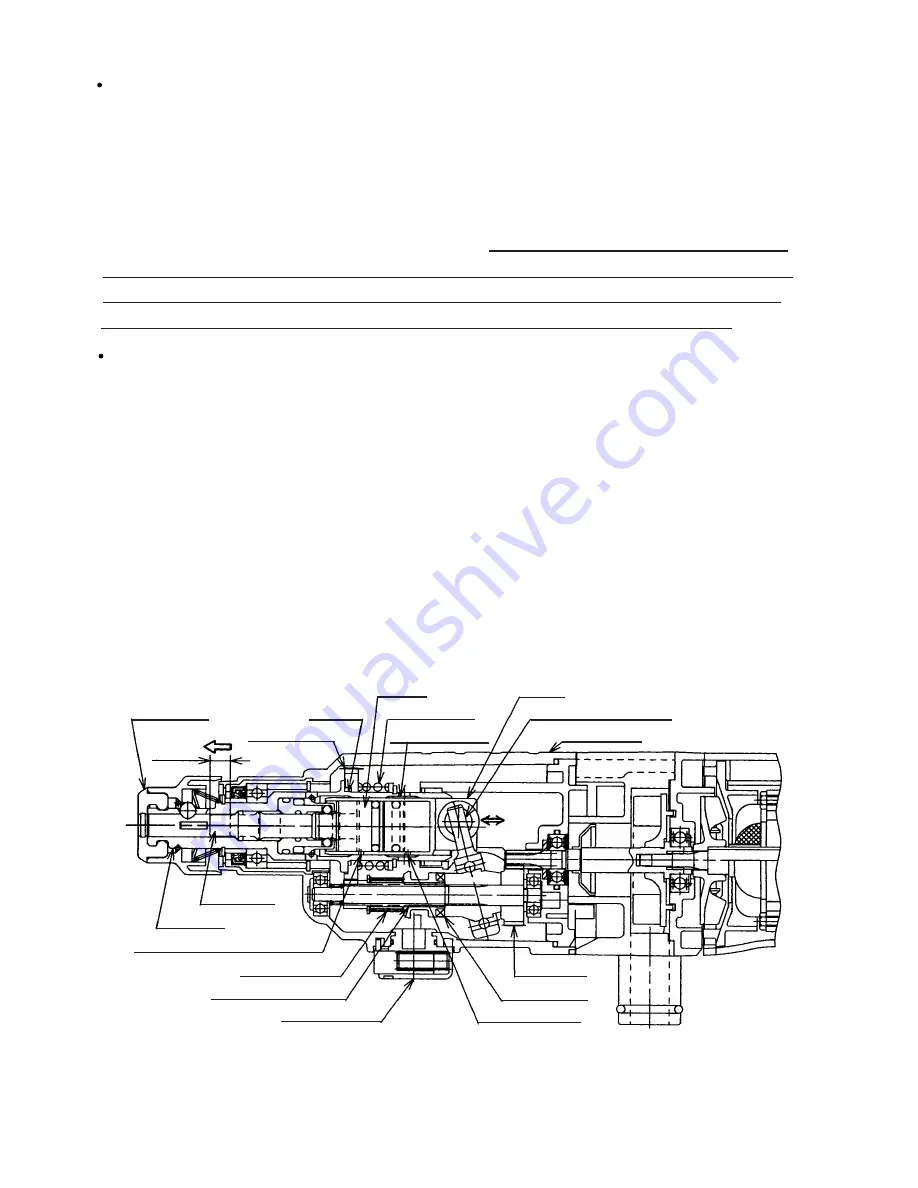

Small piston

respiratory hole

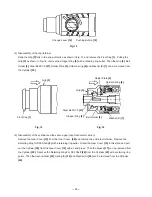

Hammering function

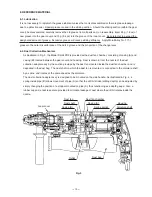

The piston reciprocates within the cylinder to move the striker in the same manner as in conventional rotary

hammers. As the piston reciprocates, the changing air pressure inside the air chamber between the piston

and the striker causes the striker to move and continuously strike against the end of the second hammer.

At the same time, the changing air pressure within the air chamber which moves the striker also provides an

"air cushion" which absorbs the impact of the hammering action. As air leakage from the air chamber would

weaken the air-cushion effect and reduce impact absorption, the O-ring (mounted on the striker) is extremely

important to seal the air. Although a special rubber material is utilized in construction of the O-ring to make its

effective service life as long as possible, wear cannot be fully avoided. Accordingly, it is recommended that

the O-ring be replaced approximately once a year, depending on the frequency of usage of the tool.

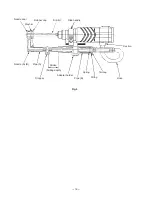

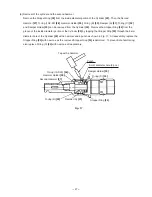

Idle hammering prevention mechanism

The idle hammering prevention mechanism in the Model DH 24PD2 is different from that of conventional rotary

hammers. When the drill bit is lifted from the concrete surface on completion of drilling, the second hammer

moves to the position indicated by the continuous lines in Fig. 6 and the protruding (lip) portion at the tip of the

striker is gripped by O-ring (C) mounted between the hammer holder and the damper holder. In this state,

should the piston continue to move so that the small piston respiratory hole is blocked by the inner wall of the

cylinder, the air in the air chamber will pass through the large piston respiratory hole and be released through

the air-escape slot and large cylinder respiratory hole provided on the inner wall of the cylinder. Accordingly,

there is no change in the air pressure within the air chamber, and movement of the striker (idle hammering

operation) is prevented. The gripping force of O-ring (C) on the striker is so small in comparison with the

conventional mouth system that practically no pressing force at all is required to restart the hammering

operation.

Piston

Front cap

Striker

Cylinder

Second

hammer

Moving

distance

Second gear

Fig. 6

First gear

Large piston respiratory hole

Claw

Coil spring

Reciprocating bearing

Gear cover

Air-escape slot

Air

chamber

Clutch spring

Second shaft spline

Change lever

Clutch claw

Summary of Contents for DH 24PD2

Page 26: ... 23 Fig 10 Dust collector B structure ...

Page 44: ......