7

28. BLADES AND ACCESSORIES MUST BE SECURELY MOUNTED TO THE TOOL.

Prevent potential injuries to yourself or others. Blades, cutting implements and

accessories which have been mounted to the tool should be secure and tight.

29. KEEP MOTOR AIR VENT CLEAN.

The tool’s motor air vent must be kept clean so that air can freely flow at all

times. Check for dust build-up frequently.

30. OPERATE POWER TOOLS AT THE RATED VOLTAGE.

Operate the power tool at voltages specified on their nameplates.

If using the power tool at a higher voltage than the rated voltage, it will result in

abnormally fast motor revolution and may damage the unit and burn up the

motor.

31. NEVER USE A TOOL WHICH IS DEFECTIVE OR OPERATING ABNORMALLY

If the tool appears to be operating unusually, making strange noises, or other-

wise appears defective, stop using it immediately and arrange for repairs by a

Hitachi authorized service center.

32. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF.

Don’t leave tool until it comes to a complete stop.

33. CAREFULLY HANDLE POWER TOOLS.

Should a power tool be dropped or struck against hard materials inadvertently

it may be deformed, cracked, or damaged.

34. DO NOT WIPE PLASTIC PARTS WITH SOLVENT.

Solvents such as gasoline, thinner, benzine, carbon tetrachloride, and alcohol

may damage and crack plastic parts. Do not wipe them with such solvents.

Wipe plastic parts with a soft cloth lightly dampened with soapy water and dry

thoroughly.

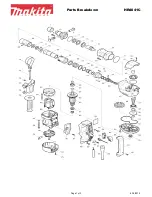

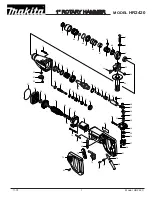

35. USE ONLY AUTHENTIC HITACHI REPLACEMENT PARTS.

Replacement parts not manufactured by Hitachi may void your warranty and

can lead to malfunction and resulting injuries. Authentic Hitachi parts are avail-

able from your dealer.

Summary of Contents for DH 24VB

Page 26: ...26 ...