-23-

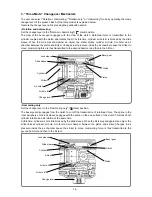

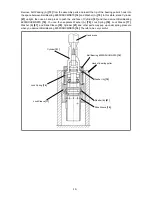

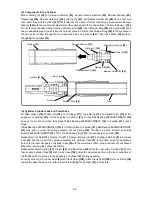

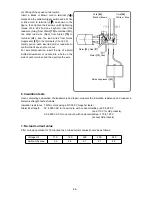

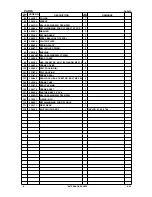

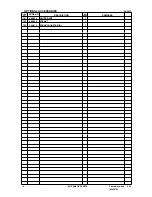

(C) Components in the Cylinder

Mount O-Ring (C)

[22]

on Second Hammer

[23]

, bundle Second Hammer

[23]

, Damper Washer

[24]

,

Damper (B)

[25]

, Damper Holder (A)

[26]

, O-Ring (A)

[27]

, and Damper Holder (B)

[28]

as one unit, and

then insert the unit into Cylinder

[21]

that is laid flat. Then push it further until it stops. Reassemble Damper

Washer

[24]

with the round inner diameter surface aligned with the round surface of Second Hammer

[23]

.

Do not reverse the assembling direction of Damper (B)

[25]

. Insert Stopper Ring

[29]

into Cylinder

[21]

and

use an adequate pipe to push it into the cylinder groove. Confirm that Stopper Ring

[29]

is firmly seated in

the groove by looking through the two inspection holes on Cylinder

[21]

. Then insert Striker

[30]

with O-

Ring

[62]

into Cylinder

[21]

.

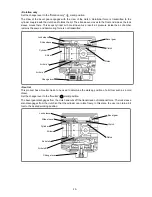

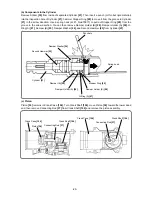

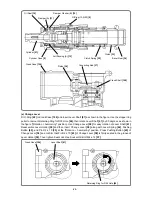

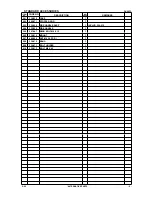

(d) Cylinder, Cylinder Case and Crank Case

Fit Slide Sleeve

[19]

, Washer (B)

[18]

, Lock Sleeve

[17]

, Lock Spring

[16]

, and Washer (A)

[15]

to the

periphery of Cylinder

[21]

. Fit these parts to Cylinder

[21]

so that Ball Bearing 6905DDUCMNS7S

[14]

does not come off, and then fully press-fit Ball Bearing 6905DDUCMNS7S

[14]

to Cylinder

[21]

until it

stops.

If Ball Bearing 6905DDUCMNS7S

[14]

is not firmly fitted to Cylinder

[21]

, Ball Bearing 6905DDUCMNS7S

[14]

may pop up under the spring pressure of Lock Spring

[16]

. Therefore, be sure to firmly push Ball

Bearing 6905DDUCMNS7S

[14]

. Then fit Felt Packing (A)

[13]

to the periphery of Cylinder

[21]

.

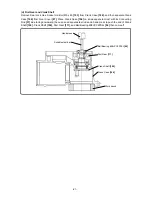

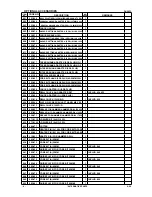

Reassemble Oil Seal

[10]

, Damper (A)

[11]

, Damper Washer (B)

[12]

, O-Ring (1AS-50)

[9]

in Cylinder

Case

[8],

and then insert the cylinder assembly into Cylinder Case

[8]

. In this case, align the depressed

portion in the inner periphery of Cylinder Case

[8]

with the projected portion in the periphery of Lock Sleeve

[17]

when inserting the cylinder assembly.

Reassemble Clutch Spring

[32]

, Clutch

[33]

, and Bevel Gear

[34]

from the rear end of Cylinder

[21]

, and

then couple Cylinder Case

[8]

with Crank Case

[104]

. Align the projected portion in the inner periphery of

Clutch

[33]

with the groove in the periphery of Cylinder

[21]

during assembly.

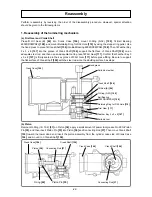

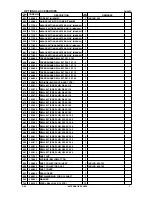

For easy coupling of Cylinder Case

[8]

with Crank Case

[104]

, rotate Crank Shaft

[106]

to move Piston

[36]

toward the upper dead end, and then insert Piston

[36]

into Cylinder

[21]

in this state.

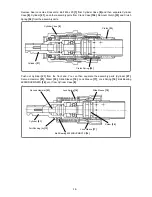

Damper (B)

[25]

Stopper Ring

[29]

Cylinder

[21]

Pipe

Groove

Hole (2 pcs.)

Damper Washer

[24]

Damper Holder (B)

[28]

O-Ring (A)

[27]

O-Ring (C)

[22]

Second Hammer

[23]

Damper Holder (A)

[26]

Cylinder

[21]