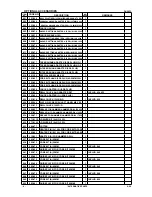

-29-

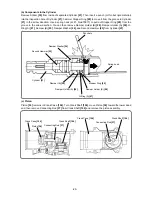

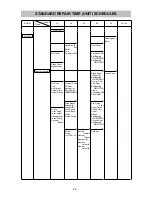

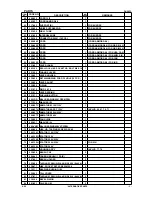

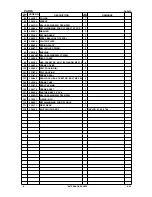

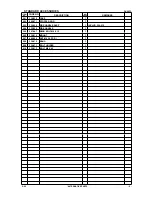

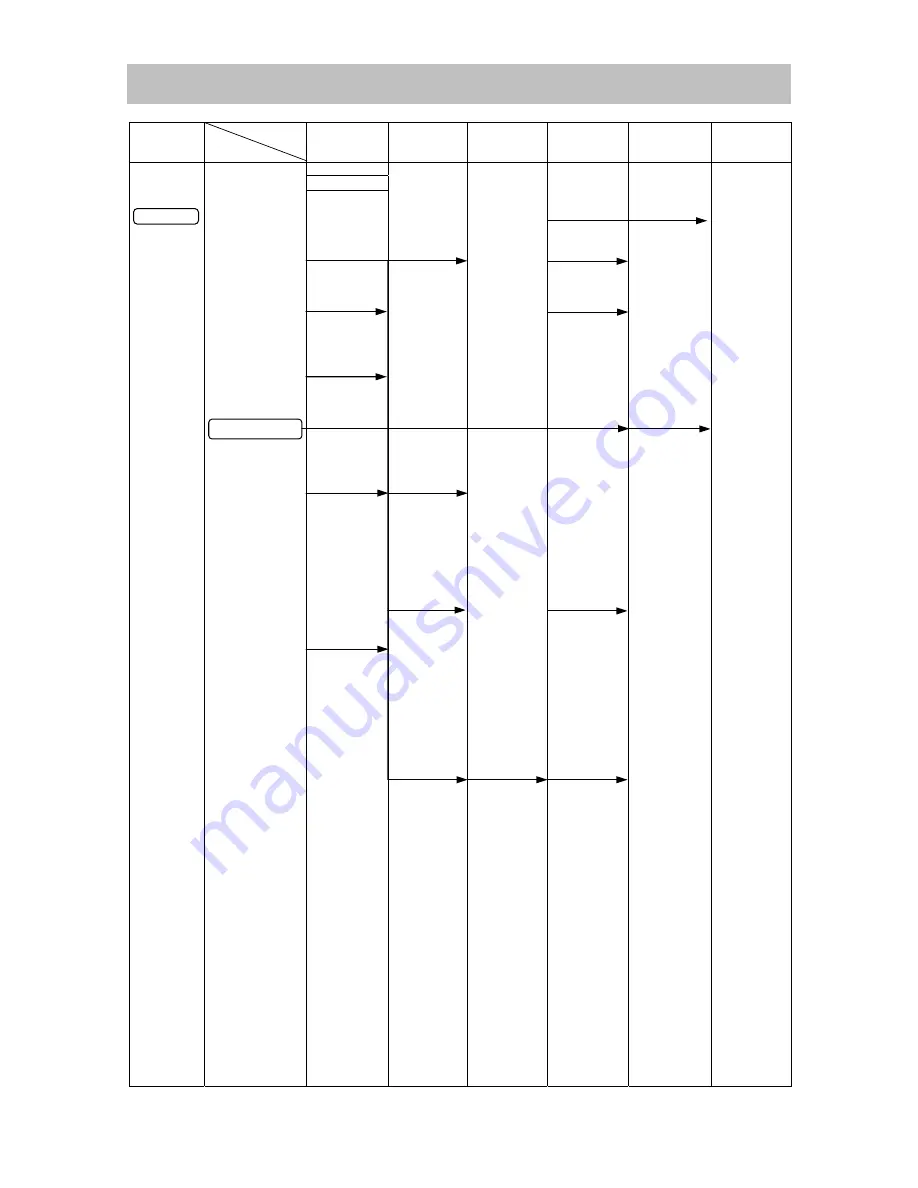

MODEL

Variable

Fixed

10

20

30

40

50

60 min.

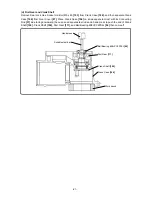

Work Flow

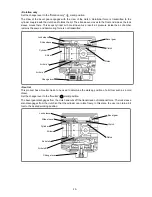

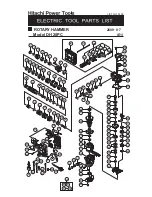

DH 28PC

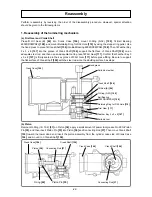

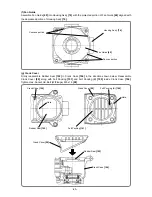

General Assembly

Tail Cover

Crank Cover

Rubber Seal

Front Cap

Grip

Ball Holder

Holder Plate

Holder Spring

O-ring

Lever Shaft

Lever Holder

Change Lever

Lever Spring

Pushing

Button

Handle (A). (B)

Set

Switch

Cord

Cord Armor D8.8

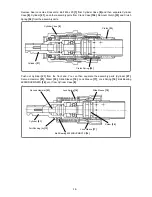

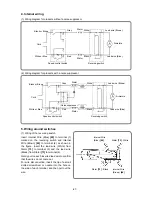

Cylinder Case

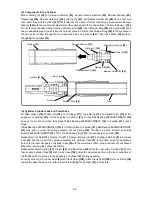

Oil Seal

Damper (A)

Ball Bearing

6905DDUCMNS7S

Slide Sleeve

Washer (A)

Washer (B)

Lock Spring

Lock Sleeve

Clutch

Clutch Spring

Striker

O-ring

(I.D 19.2) x 2

Second

Hammer

Damper

Washer

Damper (B)

Damper

Holder (A)

Damper

Holder (B)

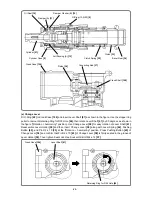

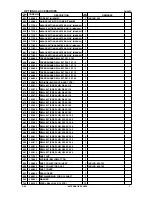

Gear Cover

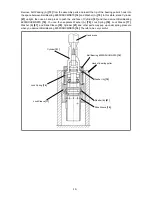

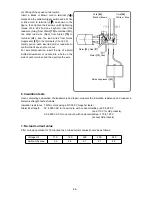

Armature Ass’y

Ball Bearing

6001DDCMPS2L

Ball Bearing

608VVC2PS2L

Crank Shaft

Oil Seal (B)

Ball Bearing

6002DDCMPS2L

O-ring (S-32)

First Gear

Ball Bearing

608VVC2PS2L

Piston

Connecting Rod

Bevel Gear

Slip Clutch

Ass’y

Bevel Pinion

Oil Seal (B)

Collar

Sleeve

Ball Bearing

6001DDCMPS2L

Second Gear

Ball Bearing

608VVC2PS2L

Cylinder

Housing Ass’y

Stator

Crank Case

STANDARD REPAIR TIME (UNIT) SCHEDULES