-12-

Fig. 17

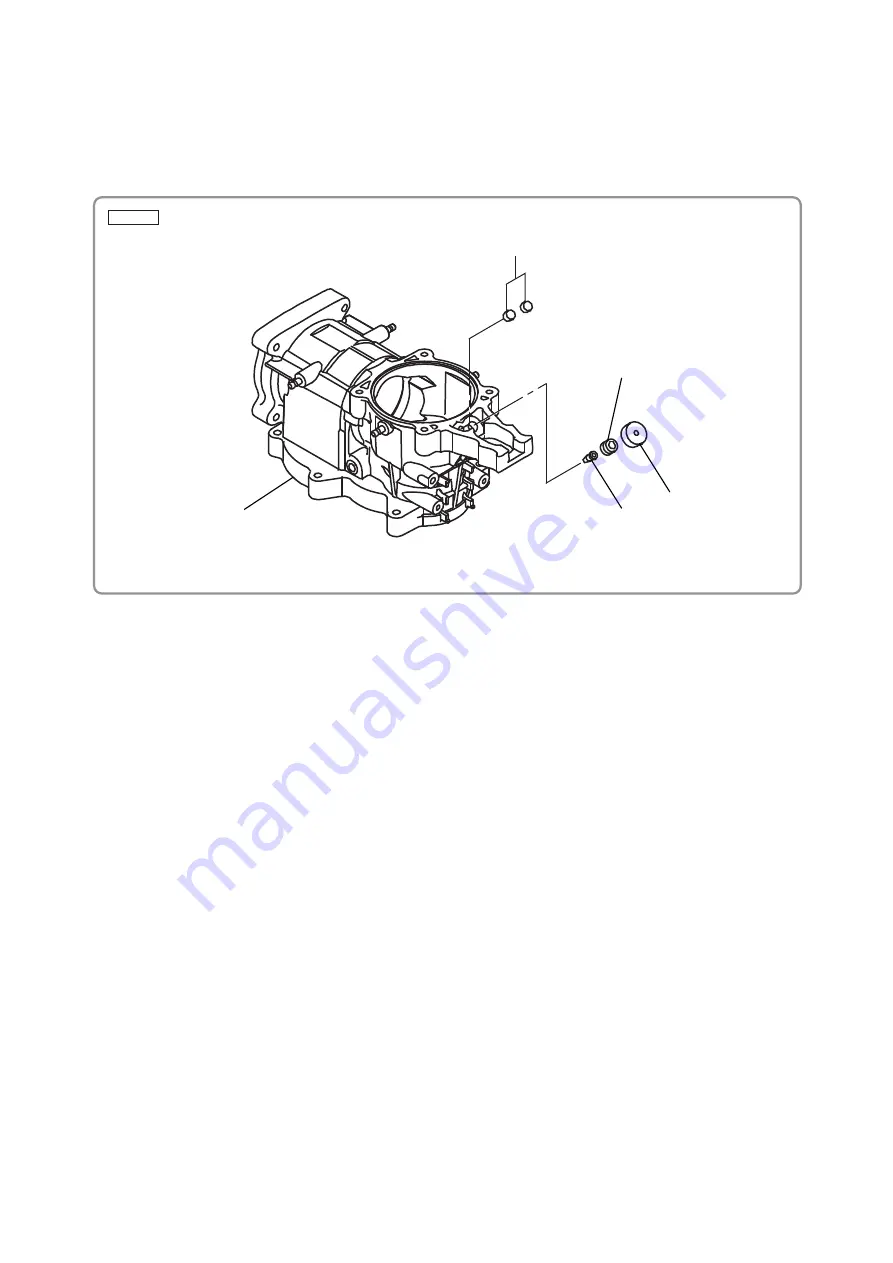

(8) Reassembly of the valve and felt

Make sure the Valve [111] is inserted in the Crank Case [89]. Grease will leak without the Valve [111].

After inserting the Valve [111], lock it with the Cap Screw [110]. Degrease the felt attaching portion of

the Crank Case [89], and then attach Felt (A) [109] with the hole on Felt (A) [109] matching the hole

on the Cap Screw [110]. Insert two Felts (B) [106] into the hole on the Crank Case [89].

2. Reassembly of the power supply unit

(1) Rotor ass’y

Before inserting the Rotor [134] into the Housing [48], mount the Rotor [134] on the Gear Cover [130].

Without the gear cover, the Rotor [134] will be strongly attracted and fixed to the Stator Sensor PCB

Set [42] by its own magnetic force. Be careful not to let your hand be suddenly pulled by the magnetic

force of the Rotor [134].

(2) Wiring of the controller set (See Fig. 18.)

• Connect the terminals of the three internal wires (red, white, and black) coming from the Stator

Sensor PCB Set [42] to the Controller Set [49] terminals of the same colors. Insert each terminal into

the mating terminal securely until it contacts the innermost end.

• Connect the 5-wire connector of the Stator Sensor PCB Set [42] to the Controller Set [49] connector.

Do not reverse the connector orientation.

• Connect the 8-wire connector of the Panel [112] to the Controller Set [49] connector. Do not reverse

the connector orientation.

(3) Wiring of the filter PCB set (See Fig. 18.)

• Connect the two terminal-equipped internal wires of the Controller Set [49] with those of the Filter

PCB Set [58]. The internal wires can be connected in any order. Insert each terminal into the mating

terminal securely until it contacts the innermost end.

• Connect the two core-exposed internal wires of the Filter PCB Set [58] to Pillar Terminal (A) [67].

[106]

[109]

[110]

[111]

[89]