English

8

CAUTION

When the warming up operation is performed, hold

the side handle and the main body securely with

both hands to maintain a secure grip and be careful

not to twist your body by the jammed drill bit.

DRILLING AND DRIVING-IN OPERATIONS FOR

ANCHORS

Use the optional accessories for anchors, such as anchor

adapter and taper shank adapter.

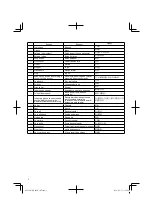

1. When a rotation hammering anchor adapter is used.

(1) Install the self-drilling anchor in the anchor adapter.

(

Fig. 8

)

(2) Turn ON the switch and drill a base hole with the self-

drilling anchor. (

Fig. 9

)

At the start of the hole-drilling slightly tilt the rotary

hammer to determine the hole position.

(3) After cleaning out dust with a syringe, attach the

plug to the anchor tip and drive in the anchor with a

manual hammer.

(4) After driving in the anchor, use the drift key to separate

the anchor. (

Fig. 10

)

(5) By employing a manual hammer or pliers, snap off

the tapered portion of the anchor. (

Fig. 11

)

CAUTION

Since the snapped-off tapered portion will fly about,

pay attention to the snapping direction.

2. When a taper shank adapter is used (Fig. 12)

(1) Install drill bit with taper shank in the taper shank

adapter.

(2) Turn the power on and drill a base hole to the depth

sounded by indicating groove on the drill bit.

(3) After cleaning out dust with a syringe, attach the plug

to the anchor tip and drive in the anchor with a

manual hammer.

(4) To remove the drill bit (taper shank), insert the cotter

into the slot of the taper shank adapter and strike the

head of the cotter with a manual hammer supporting

on a rest. (

Fig. 13

)

HOW TO HANDLE A CORE BIT

When a core bit is used, large diameter holes and blind

holes can be drilled. In this case, use optional accessories

for core bits (such as a center pin and core bit shank) for

more efficient operation.

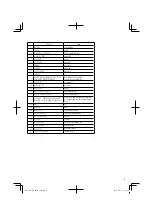

1. Mounting

CAUTION

Prior to mounting a core bit, always disconnect the

plug from the power supply receptacle.

(1) Mount the core bit on the core bit shank. (

Fig. 14

)

Before that, feed oil to the screw portion of core bit

shank for easy dismounting.

(2) Mount the core bit shank on the main body in the

same manner as in mounting the drill bit and the bull

point. (

Fig. 15

)

(3) Insert the center pin into the guide plate until it reaches

the extremity.

(4) Fit in the guide plate by aligning its concaved portion

with the core bit tip. When the position of the concave

is shifted by turning the guide plate right or left, the

guide plate never slips off even when the drill is used

in a downward direction. (

Fig. 16

)

2. Drilling holes

(1) Insert the plug into a receptacle.

(2) A spring is built in the center pin. By straightly and

gently pressing it to the wall or floor surface, the

entire surface of the core bit tip attains contact to

start the hole drilling job. (

Fig. 17

)

(3) When the hole depth reaches approximately 5 mm,

the hole position can be determined. Then remove

the center pin and guide plate from the core bit and

continue the hole drilling job.

CAUTION

When removing the center pin and guide plate, always

disconnect the plug from the receptacle.

3. How to dismount the core bit

Remove the core bit shank from the rotary hammer,

hold the core bit with one hand, and strongly strike

the head of the hexagonal shank portion of the core

bit shank with a manual hammer two or three times,

whereby the round head screw is loosened and the

rotary hammer is ready for disassembly. (

Fig. 18

)

HOW TO REPLACE GREASE

This machine is of full air-tight construction to protect

against dust and to prevent lubricant leakage. Therefore,

the machine can be used without lubrication for long

periods. Replace the grease as described below.

1. Grease replacement period

After purchase, replace grease after every 6 months

of usage. Ask for grease replacement at the nearest

Hitachi authorized Service center. Proceed for

replacement of grease.

2. Grease replenishment

CAUTION

Before replenishing the grease, turn the power off

and pull out the power plug.

(1) Remove the crank cover and wipe off the grease

inside. (

Fig. 19

)

(2) Supply 30g of Hitachi Electric Hammer Grease A

(Standard accessory, contained in tube) to the crank

case.

(3) After replenishing the grease, install the crank cover

securely.

NOTE

The Hitachi Electric Hammer Grease A is of the low

viscosity type. If necessary purchase from an Hitachi

authorized Service center.

MAINTENANCE AND INSPECTION

1. Inspecting the tool

Since use of a dull tool will degrade efficiency and

cause possible motor malfunction, sharpen or replace

the tool as soon as abrasion is noted.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure

that they are properly tightened. Should any of the

screws be loose, retighten them immediately. Failure

to do so could result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the

power tool. Exercise due care to ensure the winding

does not become damaged and/or wet with oil or

water.

01Eng_DH40SR_CKT

7/31/12, 3:13 PM

8

Summary of Contents for DH 40SR

Page 16: ...15 03ChT_DH40SR_CKT 12 7 31 15 01 15 ...

Page 17: ...16 03ChT_DH40SR_CKT 12 7 31 15 01 16 ...

Page 18: ...17 03ChT_DH40SR_CKT 12 7 31 15 01 17 ...

Page 19: ...18 A A 03ChT_DH40SR_CKT 12 7 31 15 01 18 ...

Page 20: ...19 03ChT_DH40SR_CKT 12 7 31 15 01 19 ...