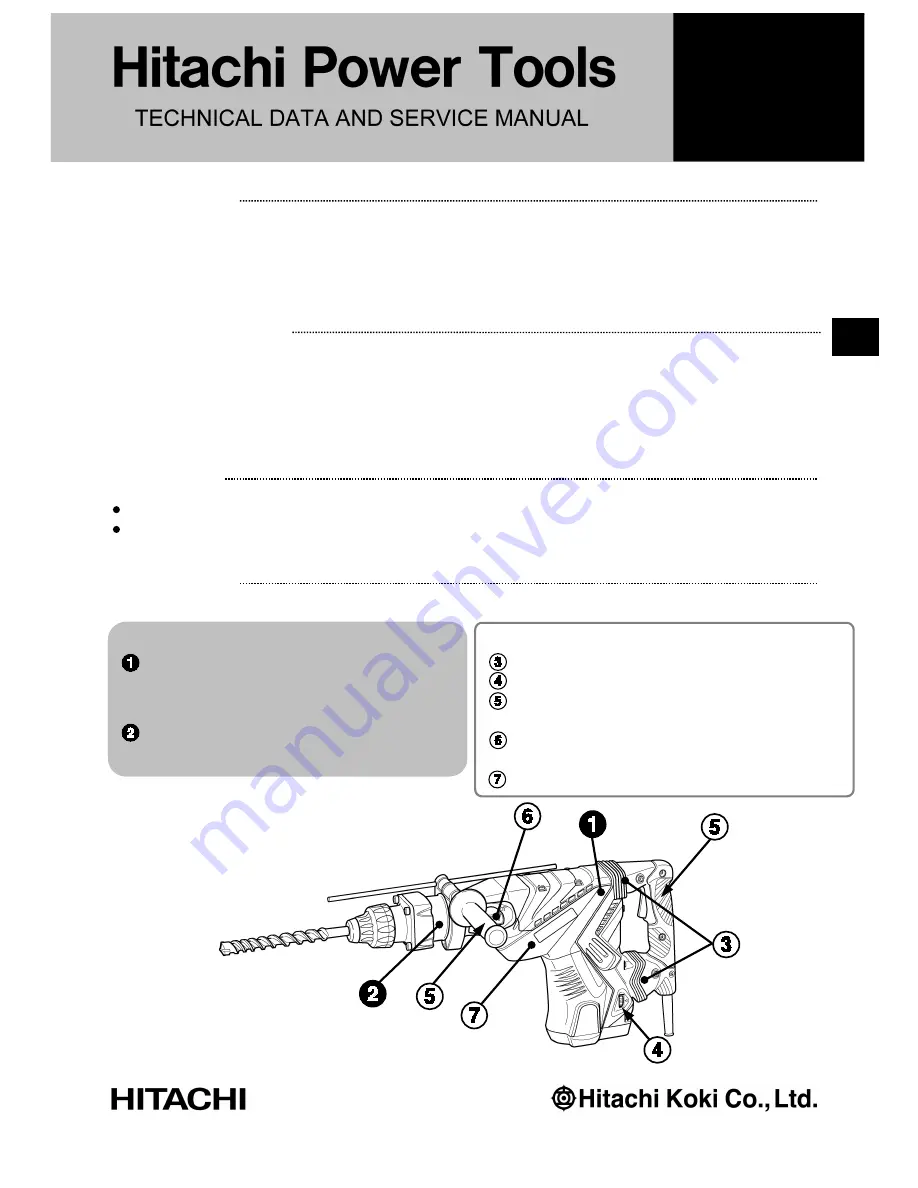

PRODUCT NAME

Hitachi Rotary Hammer

Model

DH 50MRY, DH 50MR

The new Model DH 50MRY is capable of drilling maximum 50-mm diameter holes into concrete and compatible

with SDS max shank tools. Equipped with the low vibration mechanism, the performance, durability and operability

are greatly improved. The Model DH 50MRY is released with the low-vibration hammer drill Model

DH 40MRY as our low-vibration series.

The new Model DH 50MR is an upgraded version of the current Model DH 50MB. The performance, durability and

operability are also improved greatly even though it is not equipped with the low vibration mechanism.

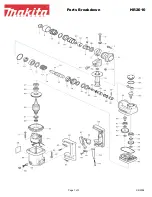

LIST Nos.

DH 50MRY: E499

DH 50MR: E498

Sep. 2007

Drilling holes in concrete and drilling anchor holes.

Demolishing and chiseling of concrete. Edging, gravel road digging, compacting and tamping, grooving,

cutting, stripping and roughing, etc.

MARKETING OBJECTIVE

APPLICATIONS

SELLING POINTS

International Sales Division

D

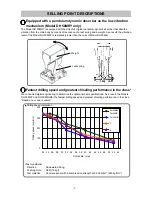

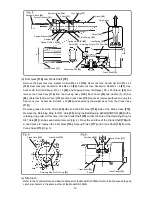

<New features>

Equipped with a pendulum dynamic absorber as

the low vibration mechanism (Model DH 50MRY

only)

Fastest drilling speed and greatest chiseling

performance in the class

<Same features as the conventional models>

Vibration-absorbing handle

Constant speed with variable speed control

Easy-to-operate and double-molded switch handle

and side handle

Variable lock mechanism for easy working-angle

adjustment of chisels etc.

Needle-pin type slip clutch

SPECIFICATIONS AND PARTS ARE SUBJECT TO CHANGE FOR IMPROVEMENT.