--- 15 ---

(h) Install the Shift Arm [19] into the assembly reassembled in step (g).

With the ridge at the Shift Arm [19] facing the Motor [28] side, first install them on the unmarked side of the

assembly reassembled in step (g). Then insert the projections on the Shift Arm [19] into the holes in the

Rear Case [17] and make sure that the projections are fitted into the grooves in the Slide Ring Gear [20]

mounted within the Rear Case [17]. (See Fig. 13.)

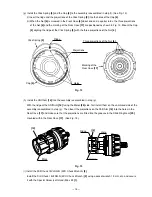

(g) Install the Click Spring [5] and the Cap [4] to the assembly reassembled in step (f). (See Fig. 12.)

(i) Insert the ridge and the projections of the Click Spring [5] into the holes of the Cap [4].

(ii) When the Nut [6] is screwed in the Front Case [9] about one and a quarter turns, the three projections

of the Nut [6] and the marking of the Rear Case [17] are positioned as shown in Fig. 12. Mount the Cap

[4] aligning the ridge of the Click Spring [5] with the three projections of the Nut [6].

Fig. 12

Click Spring [5]

Marking of the

Rear Case [17]

Holes

Ridge

Three projections of the Nut [6]

Cap [4]

Projections

Fig. 13

[19]

Ridge

[19]

Hole

Groove

Mark

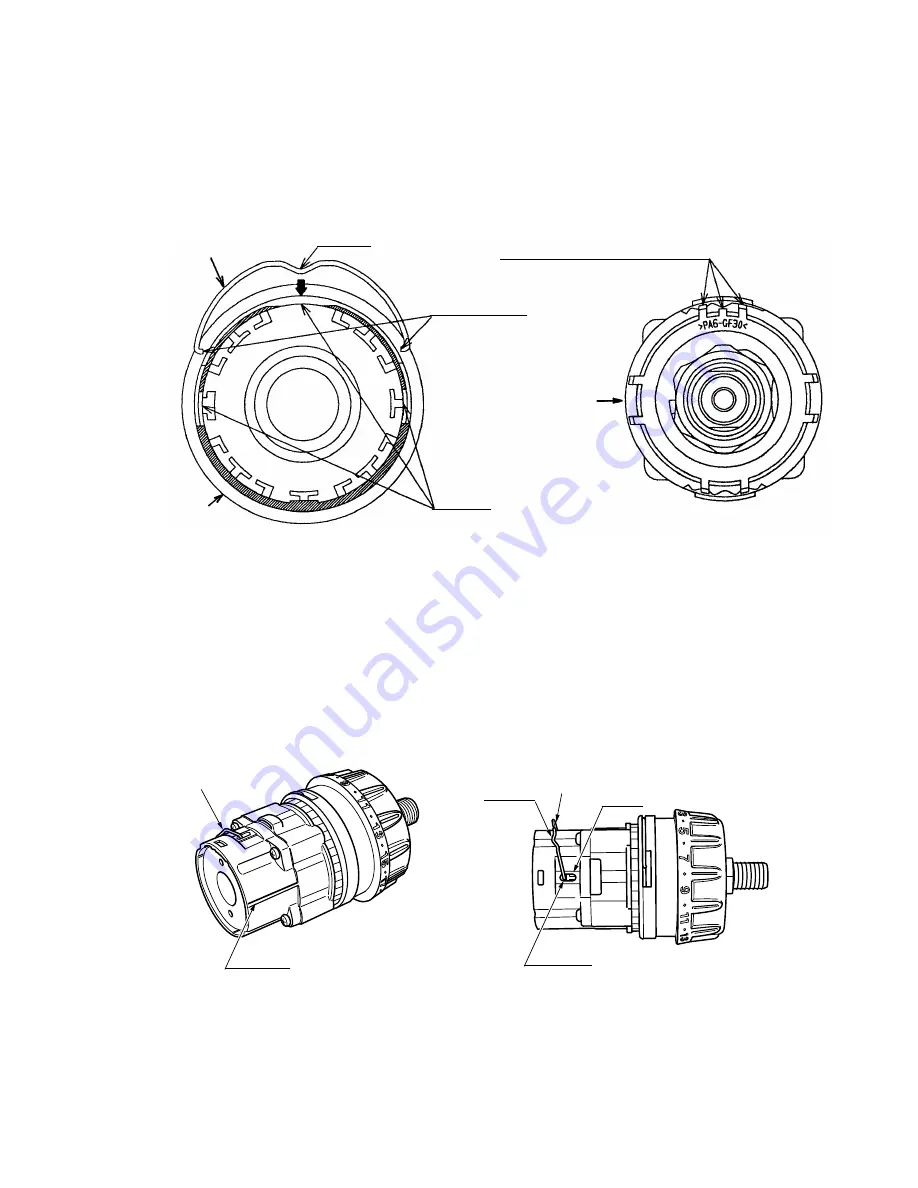

(i) Install the Drill Chuck 13VLRG-N (W/O Chuck Wrench) [2].

Install the Drill Chuck 13VLRG-N (W/O Chuck Wrench) [2] using a socket wrench 19 mm, etc. and secure

it with the Special Screw (Left Hand) M6 x 23 [1].