Reviews:

No comments

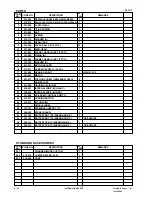

Related manuals for DS 7DF

Basic

Brand: Barbecook Pages: 48

KG845E

Brand: Euro-Pro Pages: 6

TACO BELL PROGRILL SL1577TB

Brand: Proluxe Pages: 13

BRL 3501 A

Brand: Flex Pages: 41

Prestige Pro PR0665-3

Brand: Napoleon Pages: 3

0915102

Brand: Hougen Pages: 15

BQ1084

Brand: Gasmate Pages: 16

CAT355HD

Brand: Cornwell Tools Pages: 4

27043

Brand: Jenn-Air Pages: 33

ESTIVALE PRIMA Series

Brand: Simogas Pages: 66

M18 CHX

Brand: Milwaukee Pages: 8

GDG1900

Brand: Gourmia Pages: 20

Bronco GR1031-014984

Brand: Kingsford Pages: 16

93727826

Brand: Bort Pages: 42

vida 910-05005

Brand: Paderno Pages: 35

10028749

Brand: Klarstein Pages: 11

HM-32

Brand: Hafco Pages: 27

GHD-50

Brand: Hafco Pages: 43