English

7

G

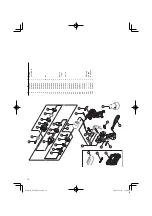

Table

2

Work

Suggestions

Drilling

Wood

Use

for

drilling

purpose.

Steel

Aluminum

Driving

Machine

screw

Use

the

bit

or

socket

matching

the

screw

diameter.

Wood

screw

Use

after

drilling

a

pilot

hole.

4.

Mounting

and

dismounting

of

the

bit.

(1)

After

inserting

a

driver

bit,

etc.

into

the

keyless

drill

chuck,

fi

rmly

grasp

the

ring

and

tighten

the

sleeve

by

turning

it

toward

the

right

(in

the

clockwise

direction

as

viewed

from

the

front)

(See

Fig.

6

).

○

If

the

sleeve

becomes

loose

during

operation,

tighten

it

further.

The

tightening

force

becomes

stronger

when

the

sleeve

is

tightened

additionally.

(2)

Dismounting

the

bit

Firmly

grasp

the

ring

and

loosen

the

sleeve

by

turning

it

toward

the

left

(in

the

counter-clockwise

direction

as

viewed

from

the

front)

(See

Fig.

6

).

CAUTION

○

When

it

is

no

longer

possible

to

loosen

the

sleeve,

use

a

vise

or

similar

instrument

to

secure

the

bit.

Set

the

clutch

mode

between

1

and

10

and

then

turn

the

sleeve

to

the

loose

side

(left

side)

while

operating

the

clutch.

It

should

be

easy

now

to

loosen

the

sleeve.

NOTE

○

There

is

a

plus

driver

bit

on

side

of

the

main

unit.

The

bit

can

be

removed

by

pulling

it

forward.

After

using

the

bit,

make

sure

to

fi

rmly

attach

it

to

the

main

body

again.

5.

Con

fi

rm

that

the

battery

is

mounted

correctly

6.

Check

the

rotation

direction

The

bit

rotates

clockwise

(viewed

from

the

rear

side)

by

pushing

the

R-side

of

the

selector

button.

The

L-side

of

the

selector

button

is

pushed

to

turn

the

bit

counterclockwise

(See

Fig.

7

).

(The

and

marks

are

provided

on

the

body.)

7.

Switch

operation

When

the

trigger

switch

is

pulled,

the

tool

rotates.

When

the

trigger

is

released,

the

tool

stops.

○

The

rotational

speed

of

the

drill

can

be

controlled

by

varying

the

amount

that

the

trigger

switch

is

pulled.

Speed

is

low

when

the

trigger

switch

is

pulled

slightly

and

increases

as

the

trigger

switch

is

pulled

more.

NOTE

○

A

peep

sound

may

be

produced

when

the

motor

is

about

to

rotate;

This

is

only

a

noise,

not

a

machine

failure.

MAINTENANCE

AND

INSPECTION

1.

Inspecting

the

tool

Since

use

of

as

dull

tool

will

degrade

e

ffi

ciency

and

cause

possible

motor

malfunction,

sharpen

or

replace

the

tool

as

soon

as

abrasion

is

noted.

2.

Inspecting

the

mounting

screws

Regularly

inspect

all

mounting

screws

and

ensure

that

they

are

properly

tightened.

Should

any

of

the

screws

be

loose,

retighten

them

immediately.

Failure

to

do

so

could

result

in

serious

hazard.

3.

Cleaning

on

the

outside

When

the

driver

drill

is

stained,

wipe

with

a

soft

dry

cloth

or

a

cloth

moistened

with

soapy

water.

Do

not

use

chloric

solvents,

gasoline

or

paint

thinner,

as

they

melt

plastics.

4.

Storage

Store

the

driver

drill

in

a

place

in

which

the

tempera

ture

is

less

than

40°C

and

out

of

reach

of

children.

5.

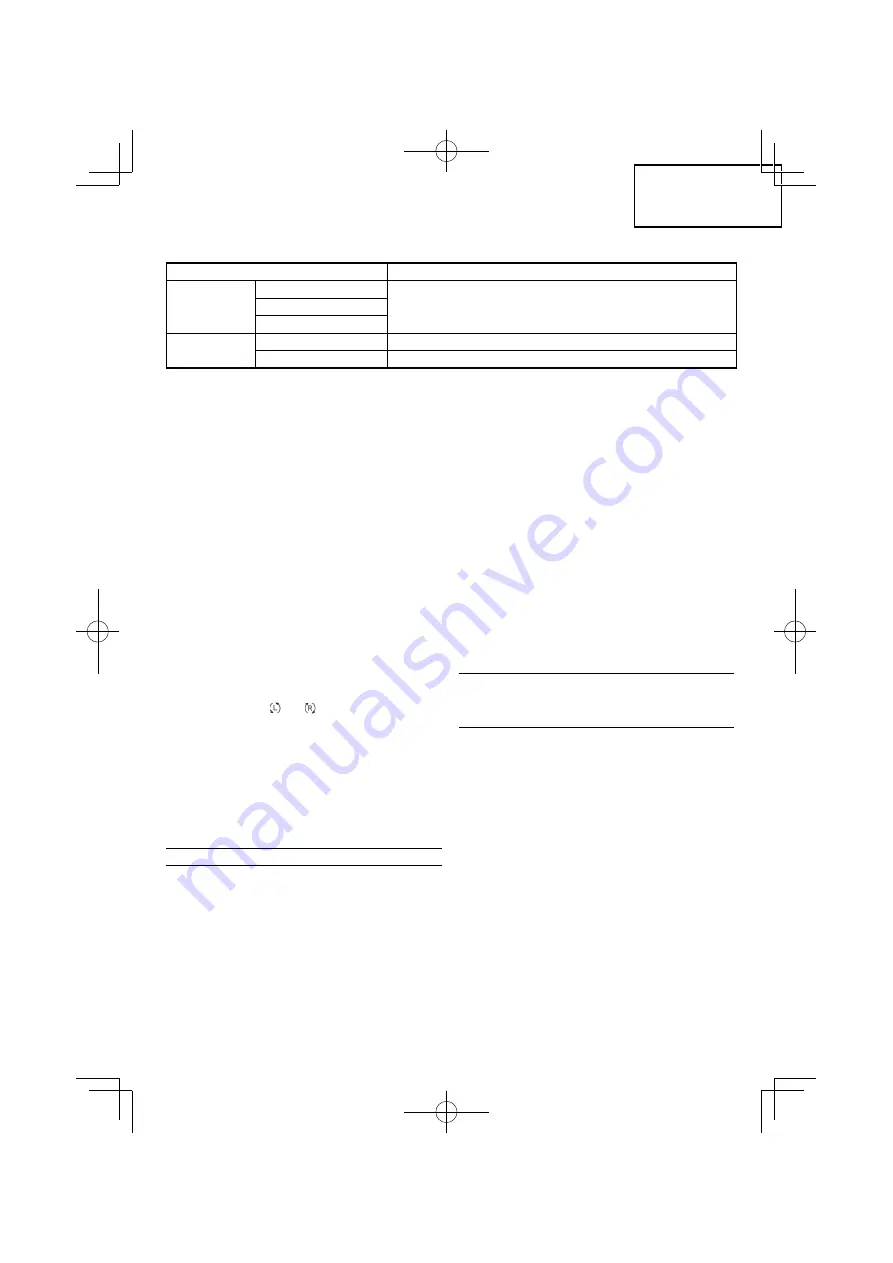

Service

parts

list

A

:

Item

No.

B

:

Code

No.

C

:

No.

Used

D

:

Remarks

CAUTION

Repair,

modi

fi

cation

and

inspection

of

Hitachi

Power

Tools

must

be

carried

out

by

a

Hitachi

Authorized

Service

Center.

This

Parts

List

will

be

helpful

if

presented

with

the

tool

to

the

Hitachi

Authorized

Service

Center

when

requesting

repair

or

other

maintenance.

In

the

operation

and

maintenance

of

power

tools,

the

safety

regulations

and

standards

prescribed

in

each

country

must

be

observed.

MODIFICATIONS

Hitachi

Power

Tools

are

constantly

being

improved

and

modi

fi

ed

to

incorporate

the

latest

technological

advancements.

Accordingly,

some

parts

(i.e.

code

numbers

and/or

design)

may

be

changed

without

prior

notice.

NOTE

Due

to

HITACHI’s

continuing

program

of

research

and

development,

the

speci

fi

cations

herein

are

subject

to

change

without

prior

notice.

000Book̲DS7DF̲Tha.indb 7

000Book̲DS7DF̲Tha.indb 7

2009/05/22 18:49:27

2009/05/22 18:49:27