34

Confidential to Customer

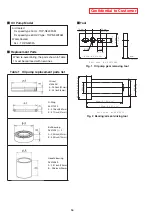

Ball Bearing

Shaft

Oil Seal

Driving-side

Rotor-side

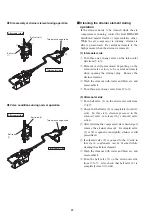

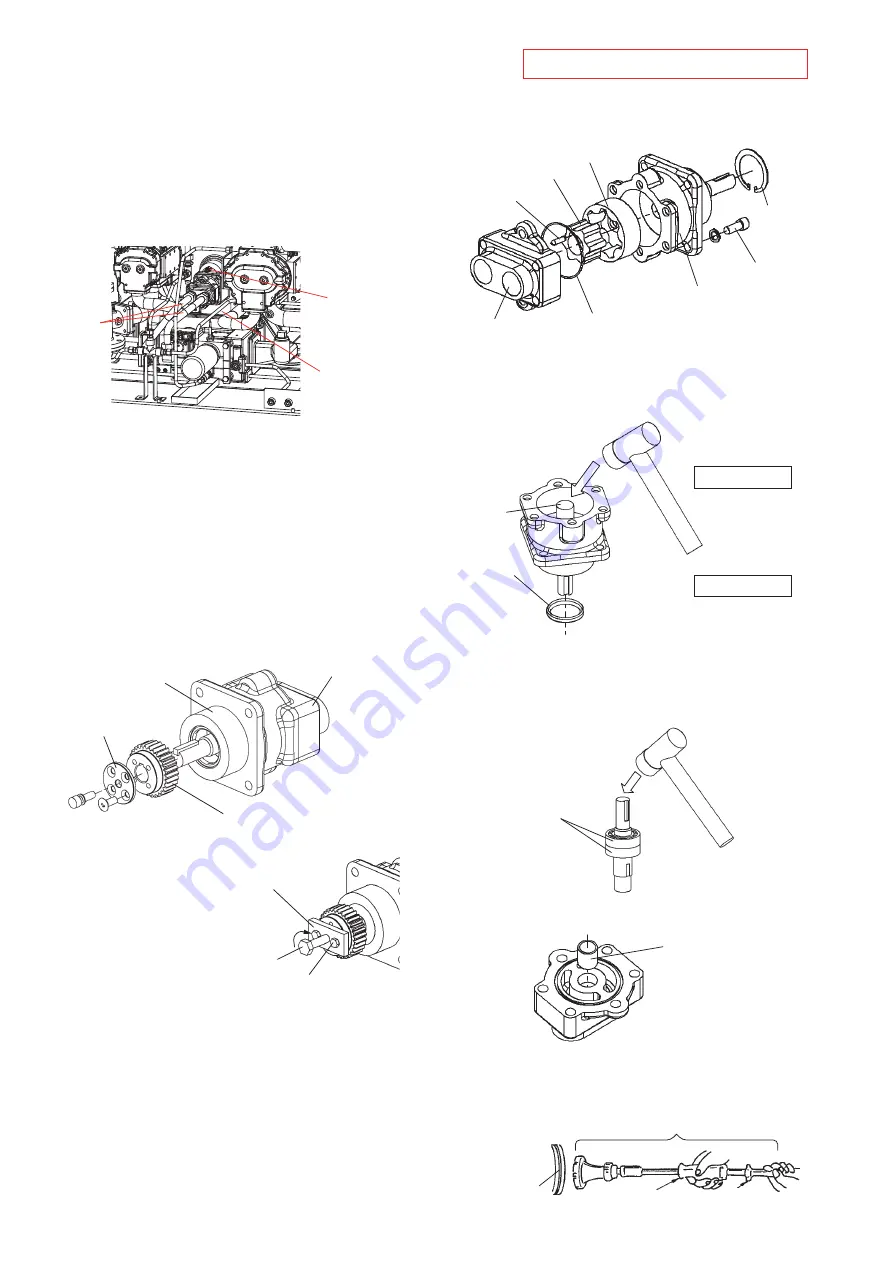

4.15 Maintenance of Oil Pump

4.15.1 Removal from the Gear Case

Remove the oil piping from the oil pump. Then, detach

the oil pump from the gear case. (When detaching the

oil pump, be careful not to damage the gear.)

4.15.2 Disassembling

①

Before disassembly, mark the matching positions on

the oil pump body and the bearing housing.

②

Remove the gear support attached to the oil pump

gear.

③

Pull out the oil pump gear using the gear removing

tool shown in Fig. 3, and then remove the key.

Gear Case

Oil Pump

Oil Piping

Gear Support

Housing

Oil Pump body

Oil Pump Gear

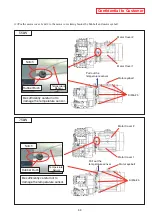

⑥

Hit the rotor-side end of shaft with a plastic or

wooden hammer; do not use a steel hammer. Thus,

the assembly of shaft, bearings and oil seal can be

removed.

Support Bolt, gear

M10 Bolt

M6 Bolt (2 places)

④

Loosen the bolts, and remove the bearing housing,

O-ring, outer rotor, inner rotor, and inner key in this

order.

⑤

Remove the snap ring.

(Removing procedure)

Fix the oil pump gear and

the gear removing tool with

M6 bolts, and remove the

gear using the axial force

of M10 bolt.

⑦

Place the removed assembly in a vice vertically; its

rotor-side end must be downwards. Hit the shaft

with a plastic or wooden hammer to remove the

bearings.

⑧

Remove the bush bearing from the bearing housing.

Inner Rotor

Outer Rotor

Inner Key

Oil Pump body

O-Ring

Housing

Bolt

Snap Ring

Bush Bearing

(Removing procedure)

Slide the hammer body to hit it strongly against the grip so

that the bearing will be removed by the impact.

Bearing Puller Set

Bush Bearing

Grip

Hammer Body