61

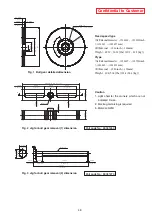

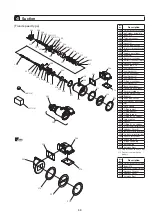

608

623

602

605

601

625

626

624

632

610

614

615

611

613

612

E76

627

E39

E39

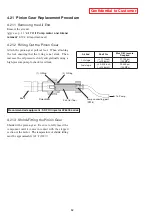

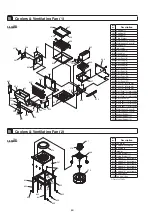

678

679

631

633

681

686

940

671

629

628

F47

634

630

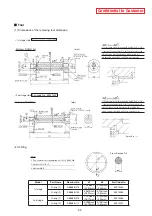

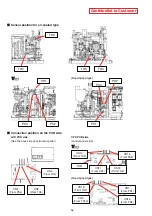

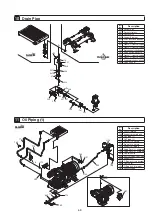

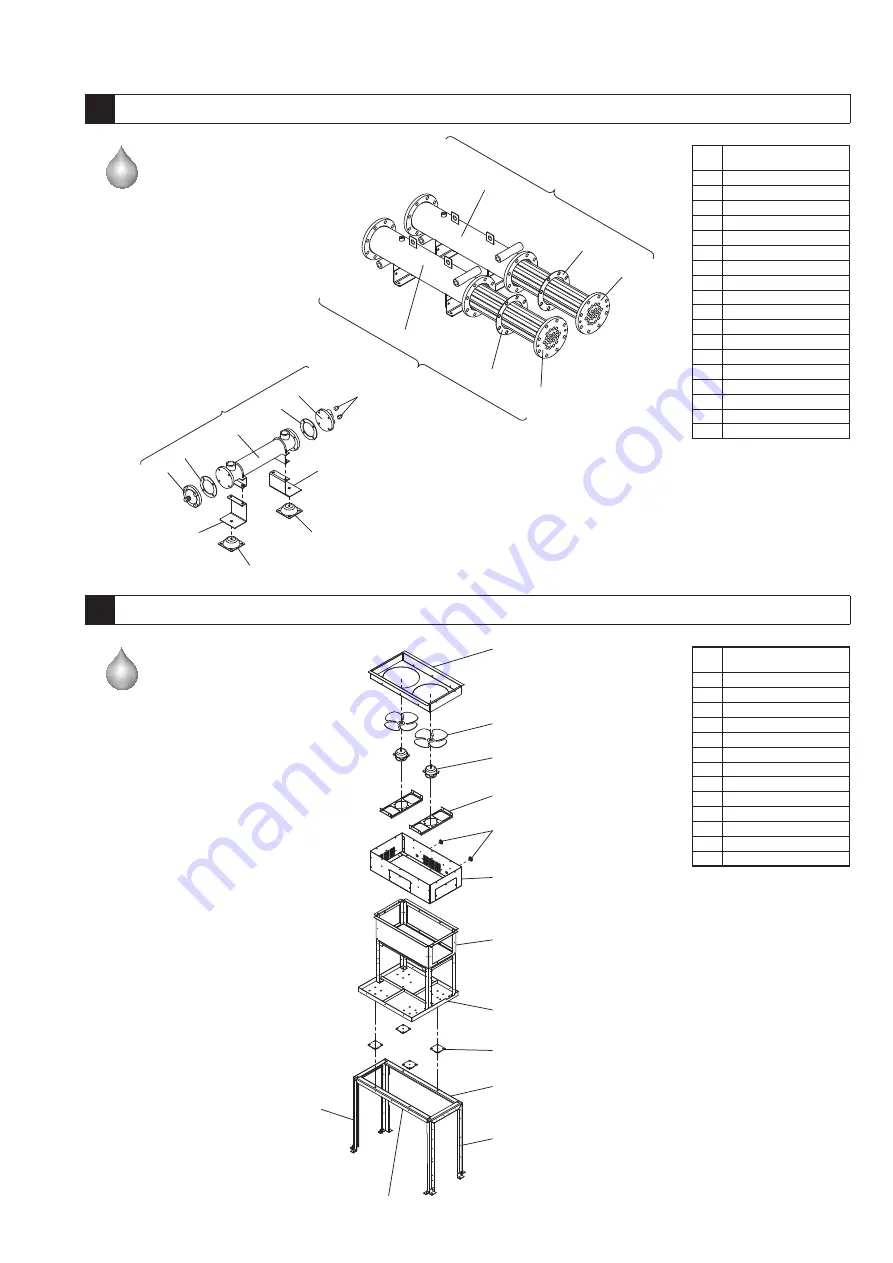

Water-Cooled

Water-Cooled

5

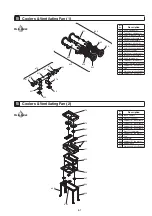

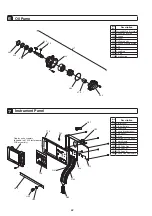

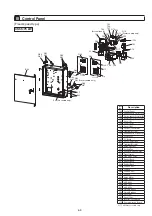

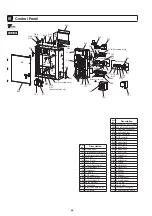

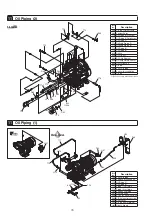

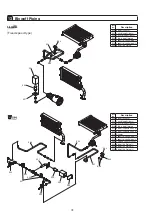

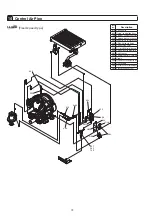

Coolers & Ventilating Fan (1)

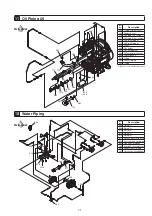

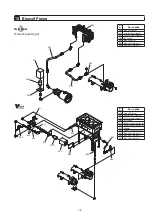

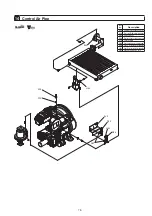

5

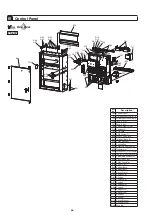

Coolers & Ventilating Fan (2)

Ref.

No.

Description

601

Shell, aftercooler

602

Tube Nest, aftercooler

605

Gasket, aftercooler tube nest

608

Aftercooler Assembly

610

Oil cooler Assembly

611

Tube Nest, oil cooler

612

Cover, oil cooler water chamber

613

Gasket, oil cooler water chamber cover

614

Cover, oil cooler

615

Gasket, oil cooler cover

623

Intercooler Assembly

624

Shell, intercooler

625

Tube Nest, intercooler

626

Gasket, intercooler tube nest

627

Support (1), oil cooler

632

Plug

E39

Vibration Isolation Rubber

E76

Support (2), oil cooler

Ref.

No.

Description

628 Base, coolers

629 Duct, air exhaust

630 Support (1), base frame

631 Support (2), base frame

633 Support (3), base frame

634 Support (4), base frame

671 Duct (1), fan motor

678 Support (2), fan motor

679 Fan

681 Fan Motor

686 Support (1), fan motor

940 Rubber Bush

F47 Vibration Isolation Rubber