Chapter 9 Maintenance, check, error

Chapter 9

Maintenance, Check, Error

Check the module dairy or regularly in order to use EH-ETH2 in best condition and keep the system run

normally.

9.1 Dairy

Check

Check the following items in operation.

AS to EH-150 series PLC, see the application manual “EH-150 application manual (NJI-280*)” or “EHV-CPU

application manual (NJI-481*)”.

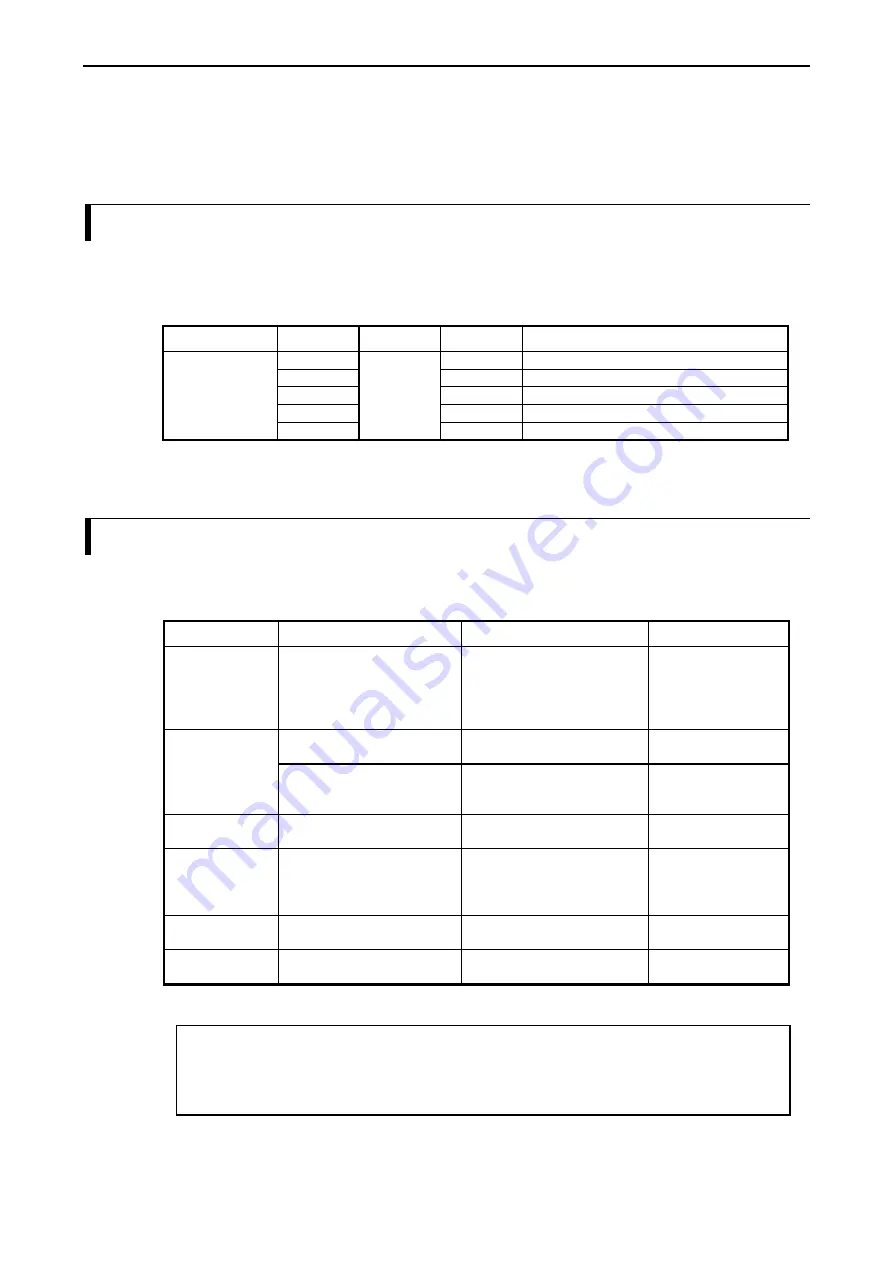

Table 9.1

Dairy check item

Check item

LED

Method

Normal

Typical cases of the problem

POW ON

Voltage

reduction

IER OFF

Ethernet

setting

ERR

OFF

Connection open error or communication error

STS

ON

Blinking : Error

(*1)

Status of LEDs

WDE

Visual check

OFF Hardware

error

*1: EH-ETH2 indicates the error content of module by the color and flash interval.

See “4.2 LED indications” for detailed information.

9.2 Regular

Check

Take the following check items with power off the PLC and external I/O circuit at least once in half of a year

or more frequently according to your condition.

Table 9.2

Regular check

Check item

Details

Measure

Action

Installation

(1) Connection between module

and base

(2) Connectors

(3) Screws

(4) Cables

Check if it is no problem.

Tighten the screws

Connect firmly

Tighten the screws

Is the cable disconnected?

Check if LINK LED of Ethernet

connector is lighting.

Change the cable.

Connection of

transmission cable

Is the cable applied irregular

weight or tension?

Check if it is no problem

Check the wiring route

and if it’s fixed

properly.

Appearance

Is the module very dusty?

Is there any unusual point?

Check if it is no problem

Cleaning up and

implement maintenance

Environment

(1) temperature

(2) humidity

(3) the others

0 to 55

°

C

20 to 90% RH (no condensing)

No dust, foreign matter,

vibration

Be sure to install in

appropriate condition

Spare module

Number of unit, storage

condition

Check if it is no problem

-

Program

Check program

The final programs in CPU and

in PC must be the same.

Check both master and

backup program.

* Be careful not to change the module setting switch by mistake when you clean the module.

CAUTION at the time of the module exchange.

・

We recommend that the module exchange is done under the connected equipment's power OFF.

MAC ID for the address resolution managed in the connected equipment side might not be updated if the

module exchange is done under the connected equipment's power ON, and therefore, the communication

cannot start.

9-1