MAINTENANCE

7-44

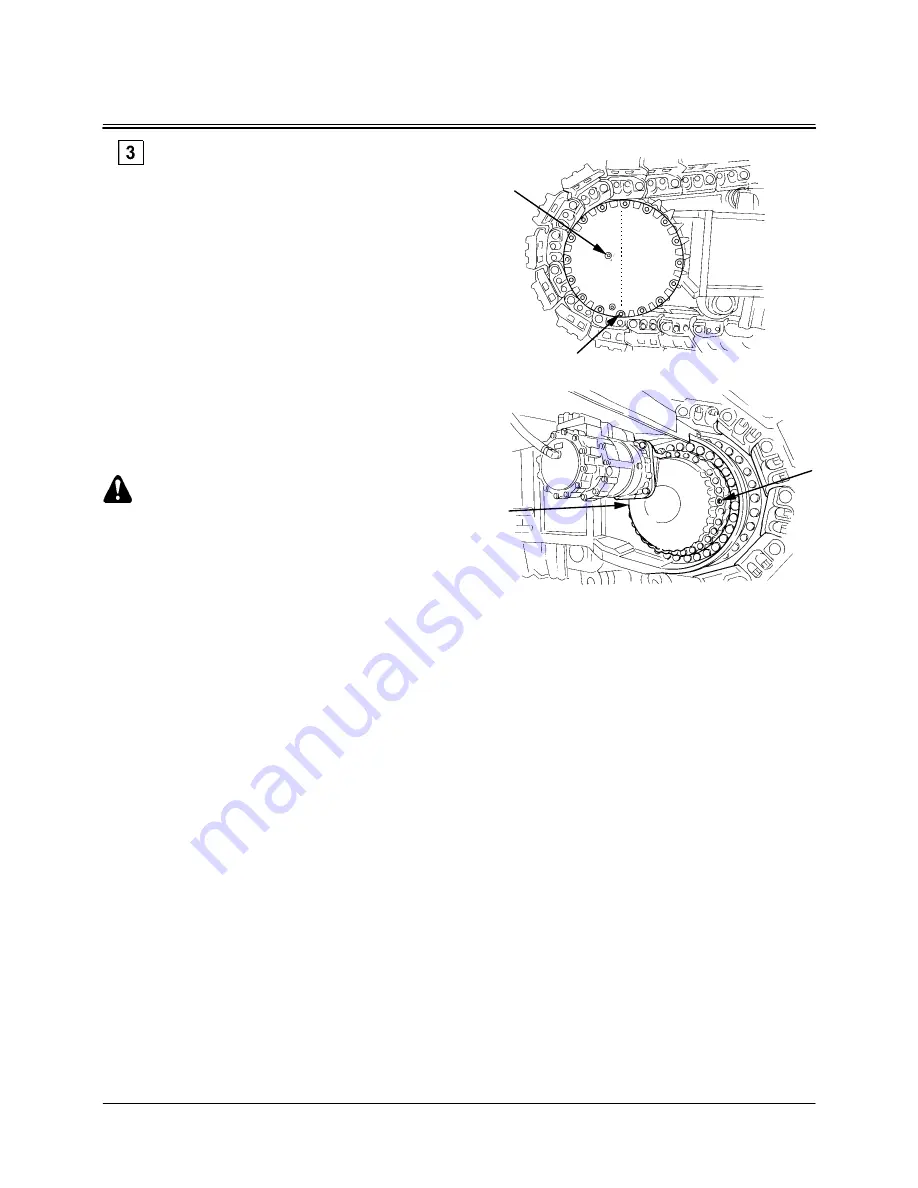

Travel Reduction Gear

Check Oil Level --- every 250 hours

1. Park the machine on a level surface.

2. Lower the bucket to the ground.

3. Turn the auto-idle switch off.

IMPORTANT: The turbocharger may be damaged if the

engine is not properly shut down.

4. Run the engine at slow idle speed without load for five

minutes.

5. Stop the engine. Remove the key from the key switch.

6. Pull the pilot control shut-off lever to the LOCK

position.

CAUTION: Keep body and face away from oil

level check plug (air release plug) (1). Gear oil is

hot. Wait for gear oil to cool and then gradually

loosen oil level check plug (air release plug) (1) to

release pressure.

7. After gear oil has cooled, slowly loosen oil level check

plug (air release plug) (1) to release pressure.

8. Remove oil level check plug (1). Oil must be up to the

bottom of hole.

9. If necessary, after oil supply plugs (2) have been

removed, add oil until oil flows out of the oil level

check plug hole. (See gear oil chart).

10. Wrap oil level check plug (1) threads with sealing-type

tape. Install oil level check plug (1).

Tighten the plug to 196 N

x

m (20 kgf

x

m, 145 lbf

x

ft).

11. Wrap oil supply plug (2) threads with sealing-type

tape. Install oil supply plug (2). Tighten oil supply plug

(2) to 69 N

x

m (7 kgf

x

m, 51 lbf

x

ft).

12. Check the gear oil level in the other travel reduction

gear.

M144-07-017

M144-12-002

1

2

2

Park the machine so that this bolt is

just at the bottom position.

Summary of Contents for EX1900-5

Page 1: ......

Page 37: ...SAFETY SIGNS S 29 SS 411 SS 691 SS 442 M18C 01 006 SS 445 M144 07 107 ...

Page 38: ...SAFETY SIGNS S 30 SS 446 SS 723 SS3076117 SS 723 SS 410 SS 723 Loading Shovel ...

Page 39: ...SAFETY SIGNS S 31 SS3091476 M146 01 035 ...

Page 40: ...SAFETY SIGNS S 32 SS 413 M18C 01 007 M18C 01 008 ...

Page 42: ...SAFETY SIGNS S 34 MEMO ...

Page 112: ...DRIVING THE MACHINE 4 12 MEMO ...

Page 140: ...MAINTENANCE 7 8 MEMO ...

Page 146: ...MAINTENANCE 7 14 Hoses Q ty in Use Transmission Oil Cooler Hose 5 2 M18C 07 062 5 ...

Page 156: ...MAINTENANCE 7 24 4 Grouped Grease Fittings 7 Arm Ñ Lubrication M144 07 079 M144 07 005 7 ...

Page 258: ...MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS 9 2 MEMO ...

Page 274: ...TROUBLESHOOTING 11 14 MEMO ...

Page 278: ...SPECIFICATIONS 12 4 MEMO ...