ENGLISH

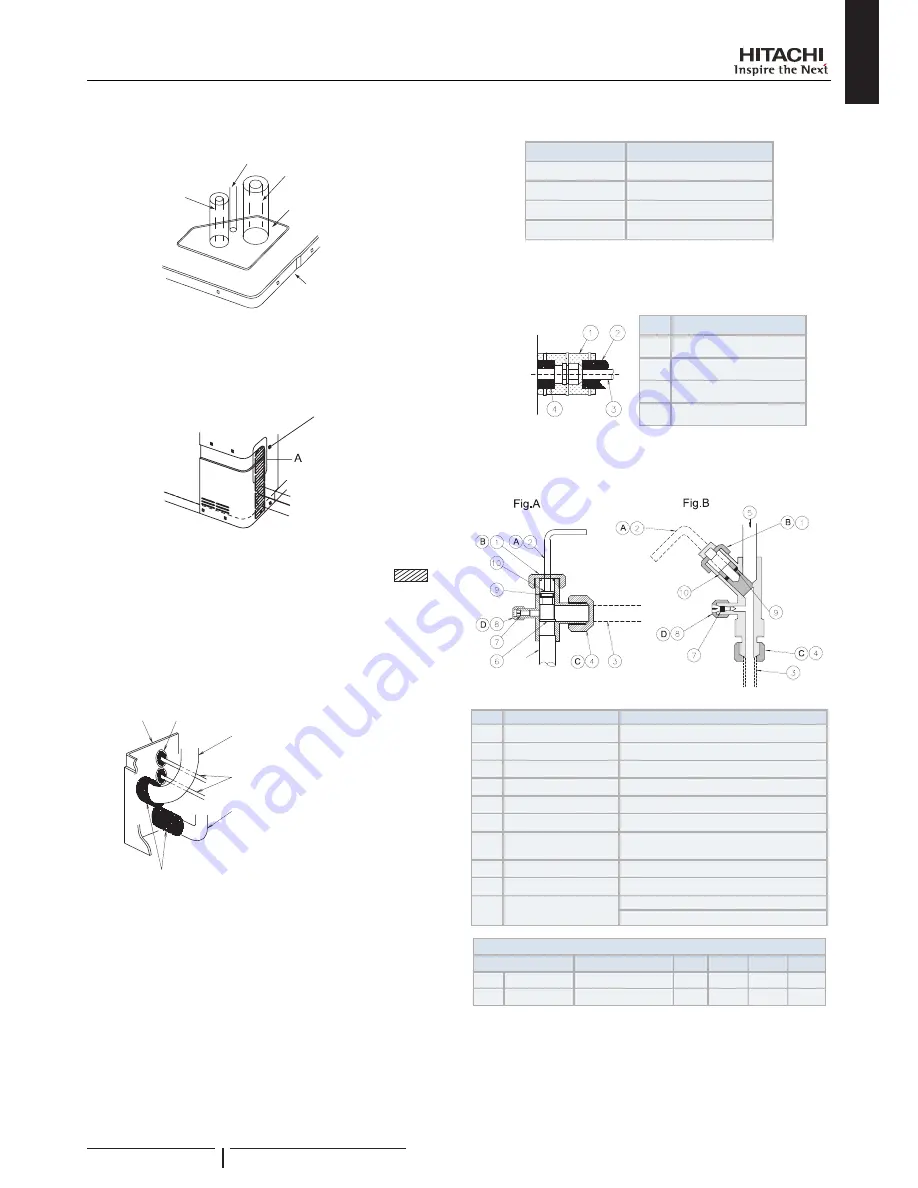

For the downward piping

Gas piping

Knock-out hole

Bottom base

Cables

Liquid piping

?

N O T E

Cables shall not contact directly to the pipes.

For the rear side piping

Rear Cover

?

N O T E

Remove the rear pipe cover under the rear cover and remove

part

following the slit.

6

Mount the piping cover in order to avoid water entering into

the unit. Seal the holes where pipes and wires are inserted,

by using a insulator and rubber bushes as shown below.

Piping

cover

Rubber bush (Accessory)

Add cross cutting to the center of the rubber bushing.

Attach rubber bushing to the hole of wiring.

In case that conduit tube is used, rubber bush is not

necessary.

Gas pipe

Power source and operating wiring

Liquid pipe

Insulation (Accessory).

Attach insulation to the pipe as shown in the figure and space shall not

exist at the piping hole.

Cut the insulation as shown in the figure when attaching work is difficult.

7

If the field-supplied piping is connected with stop valves

directly, it is recommended use a tube bender.

8

Check to ensure that the stop valves are closed completely

before connecting pipes.

9

Connect the field supplied refrigerant pipes to the indoor unit

and outdoor unit. Apply the oil thinly at the seat flare nut and

pipe before tightening.

The required tightening torque is as follows:

Pipe Size

Tightening Torque (Nm)

Ø 6.35 mm

20

Ø 9.52 mm

40

Ø 12.70 mm

60

Ø 15.88 mm

80

10

After connecting the refrigerant piping, seal the open space

between knockout hole and refrigerant pipes by using

insulation material.

Unit

side

Nº

Description

Insulation Material

Insulation Material

Field Supplied

Insulation Material

11

Operation of stop valve should be performed according to

the figure below.

Close before shipment

Nº

Description

Remarks

Cap

Allen wrench

Fig.A: Hex 4 mm / Fig.B: Hex. 8 mm

Refrigerant Piping

Field Supplied

Flare nut

Refrigerant pressure To Outdoor Unit

Seat Surface

Fully closed position

Check Joint

Only the charging those can be

connected

Cap

O-Ring

Rubber

Spindle valve

Open – Counterclockwise

Close – Clockwise

Tightening Torque (Nm)

Valve type

Model

A

B

C

D

Fig.A Liquid valve (4~6)HP

7-9

37

40

16

Fig.B Gas valve

(4~6)HP

9-11

30

60

9

REFRIGERANT PIPING & REFRIGERANT CHARGE

PMML0354A rev.1 - 03/2015

11