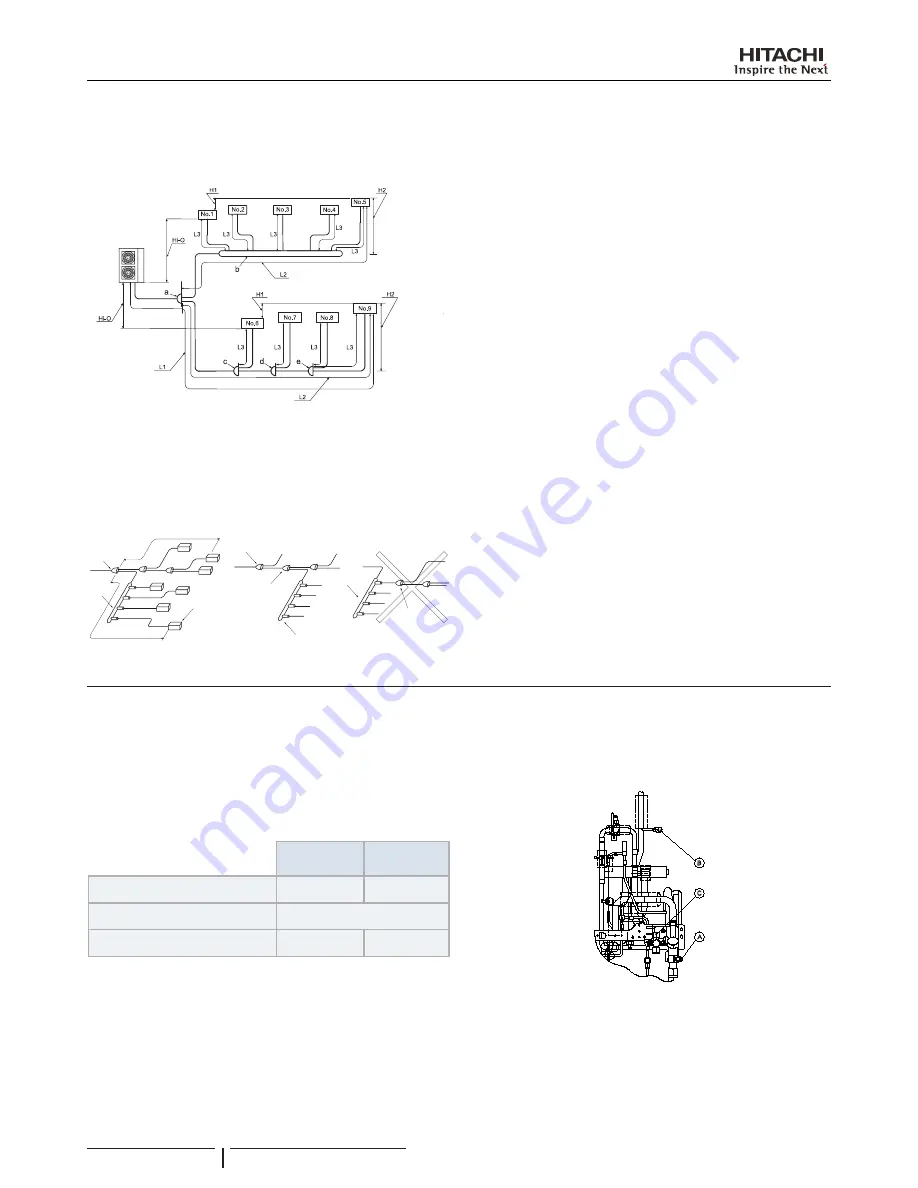

11.6.3 Combination branch piping system

Installation type

Considerations

It is possible to connect the header to the second branch, when

the first branch is also the line branch.

Do not connect a line branch to a header branch.

Header

Line

branch

Header

Indoor unit

Max. 40 m

Max. 40 m

Second branch

Line branch

(First branch)

Line branch

(First branch)

Header

11.6.4

Brazing work

!

C A U T I O N

•

Use nitrogen gas for blowing during pipe brazing. If oxygen, acetylene

or fluorocarbon gas is used, it will cause an explosion or poisonous

gas.

•

A lot of oxidation film will occur inside of tubes if no nitrogen gas blow

-

ing is performed during brazing work. This film will be flecked off after

operation and will circulate in the cycle, resulting in clogged expan

-

sion valves, etc. This will cause bad influence to the compressor.

•

Use a reducer valve when nitrogen gas blowing is performed during

brazing. The gas pressure should be maintained within 0.03 to 0.05

Mpa. If a excessively high pressure is applied to a pipe, it will cause

an explosion.

11.6.5 Refrigerant charge

!

C A U T I O N

•

Do not charge OXYGEN, ACETYLENE, or other flammable and poi

-

sonous gases into the refrigerant because an explosion can occur. It

is recommended that oxygen free nitrogen be charged for these types

of tests cycle when performing a leakage test or an airtight test. These

types of gases are extremely dangerous,

•

Insulate the unions and flare-nuts at the piping connection part com

-

pletely.

•

Insulate the liquid piping completely to avoid a decrease of perfor

-

mance; if not, it will cause sweating on the surface of the pipe.

•

Charge refrigerant correctly. Overcharging or insufficient charging

could cause a compressor failure.

•

Check for refrigerant leakage in detail. If a large refrigerant leakage

occurred, it would cause difficulty with breathing or harmful gases

would occur if a fire were being used in the room.

•

If the flare nut is tightened too hard, the flare nut may crack after a

long time and cause refrigerant leakage.

11.7 CAUTION OF THE PRESSURE BY CHECK JOINT

When the pressure is measured, use the check joint of gas stop

valve (A), and use the check joint of liquid piping (B) in the figure

below.

At that time, connect the pressure gauge according to the

following table because of high pressure side and low pressure

side changes by operation mode.

Cooling

operation

Heating

operation

Check joint for gas stop valve “A”

Low pressure

High pressure

Check joint for piping “B”

Exclusive for vacuum pump

Check joint for liquid stop valve “C”

High pressure

Low pressure

?

N O T E

Be careful that refrigerant and oil do not splash to the electrical parts at

removing the charge hoses.

REFRIGERANT PIPING & REFRIGERANT CHARGE

PMML0354A rev.1 - 03/2015

18