--- 8 ---

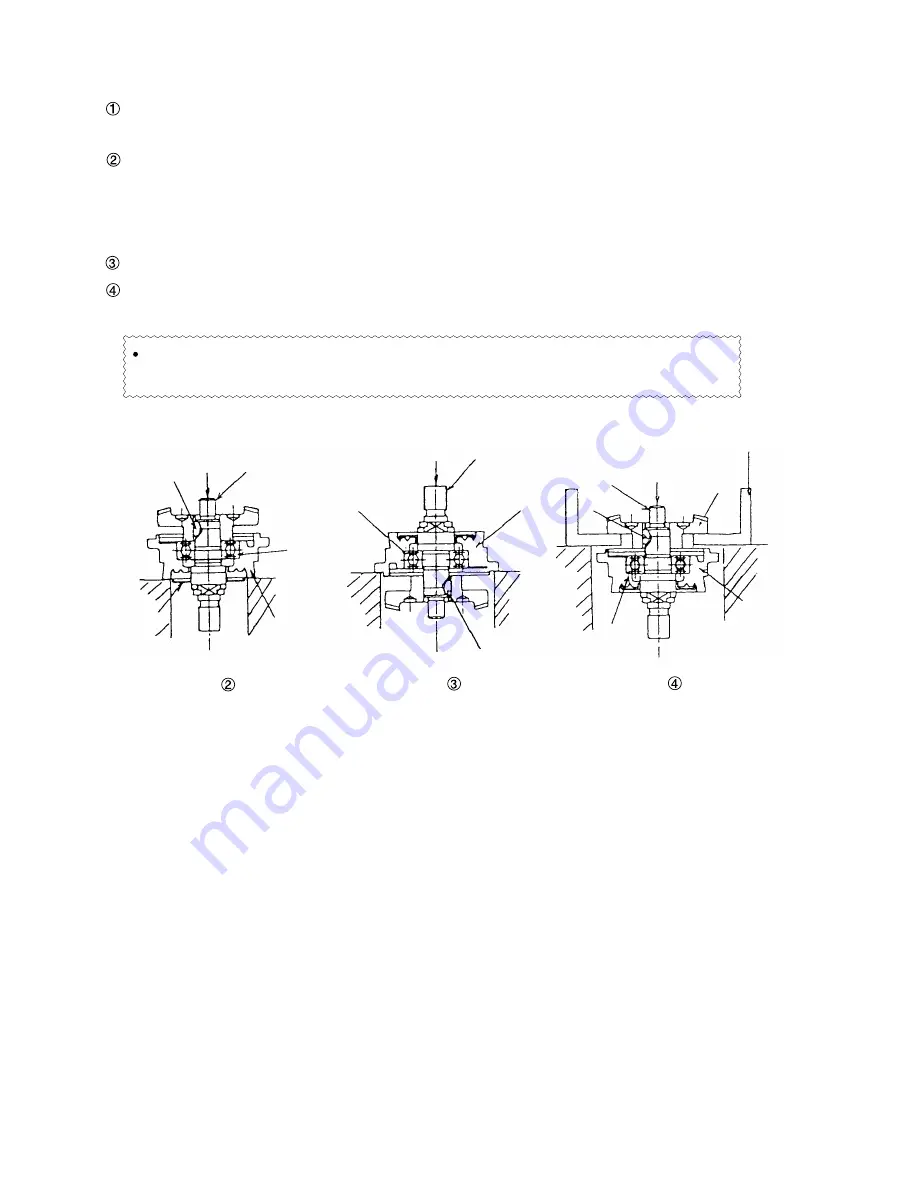

(4) Disassembly of the gear (Fig. 3)

Loosen the Seal Lock Screw (W/Sp. Washer) M4 x 12 [23] fixing the Packing Gland [22], and remove the

Packing Gland [22] from the Gear Cover Ass'y [3].

Support the button of the Packing Gland [22] with a jig, and push down on the upper portion of the Spindle

M10 x P1.5 [25] with a hand press until the end surface of the Woodruff Key 2.5 x 8 [24] contacts the Ball

Bearing 6001VVCMPS2L [20] and the Spindle M10 x P1.5 [25] cannot be pushed down any more. Be

careful not to deform the Fringer [26].

Turn the Packing Gland [22] upside down and fix it, then push down the Spindle M10 x P1.5 [25].

Insert the gear puller J-128 (use of a steel plate is permitted as a substitute) between the Gear [17]

and the Packing Gland [22], and push down the Spindle M10 x P1.5 [25] with a hand press to remove it.

[25]

[24]

[26]

Fig. 3

Replace the Ball Bearing 6001VVCMPS2L [20] with new one every time the Gear is disassembled

because the force to pull out the Gear is applied to the Ball Bearing 6001VVCMPS2L [20].

[20]

[25]

[20]

[22]

Push

Push

Push

[24]

[22]

[20]

[25]

[22]

[17]

Step

Step

Step

Gear puller J-128

(steel plate)

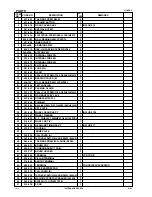

Summary of Contents for G 10SF3

Page 21: ......